Low-cost intelligent chip carrier band and manufacturing method therefor

A smart chip, low-cost technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of cavity deformation, low mold coverage rate, high price, etc., to reduce manufacturing cost and material cost , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

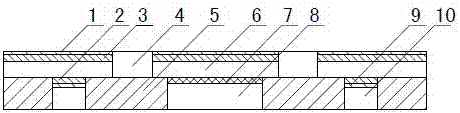

[0034] Figure 1~11 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~11 The present invention will be further described.

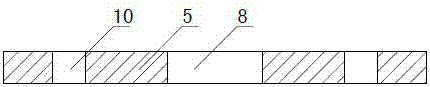

[0035] Such as figure 1 As shown, a low-cost smart chip carrier tape includes a carrier tape base material 5, and a plurality of contact blocks are formed on the upper surface of the base tape base material 5 through insulating grooves 4. The combined copper foil layer 6 and the contact nickel layer 3 and the contact gold layer 1 above the copper foil layer 6. A cavity 8 is opened in the middle of the lower surface of the carrier tape substrate 5, and a welding hole 10 corresponding to the contact block is provided on the outer ring of the cavity 8, and the copper foil layer corresponding to the corresponding position is covered in the welding hole 10. The welded nickel layer 2 bonded to 6 and the welded nickel layer 2 are covered with an insulating layer 7 bonded to the copper foil layer 6 at the corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com