Stirring machine for shredded sweet potato candy

A technology of blender and saccharide, which is applied in confectionery, confectionery industry, food science and other directions, can solve the problems of increasing the stirring time, not easy to mix evenly, and unable to realize continuous feeding and stirring of sweet potatoes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below by means of specific embodiments:

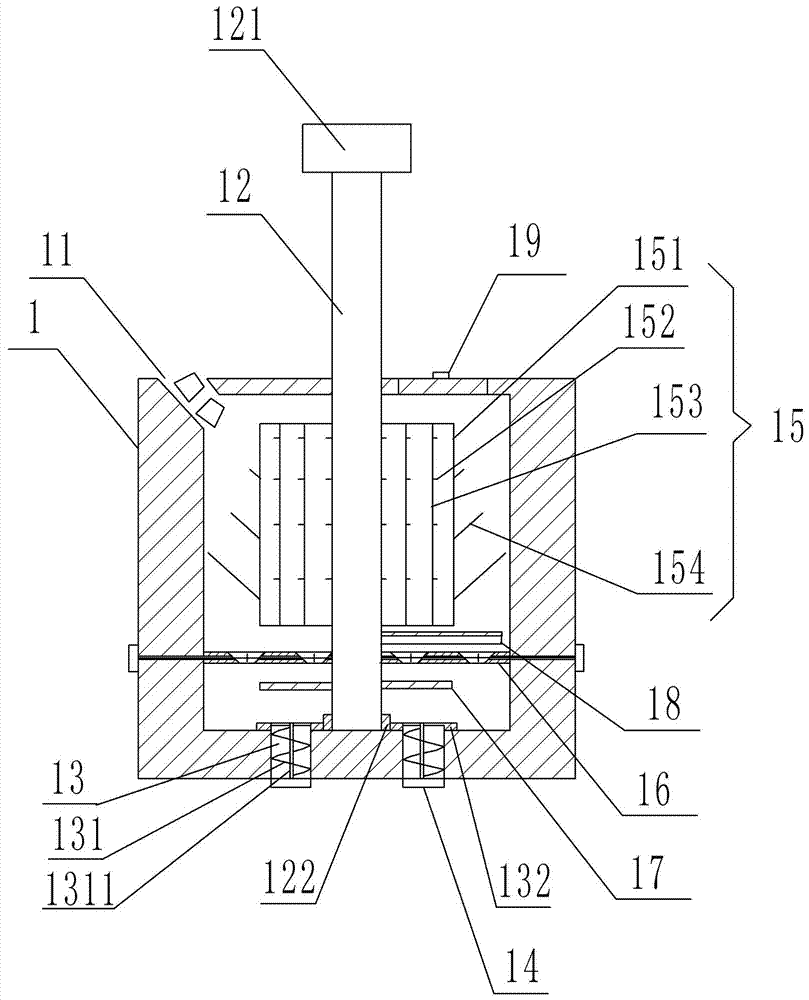

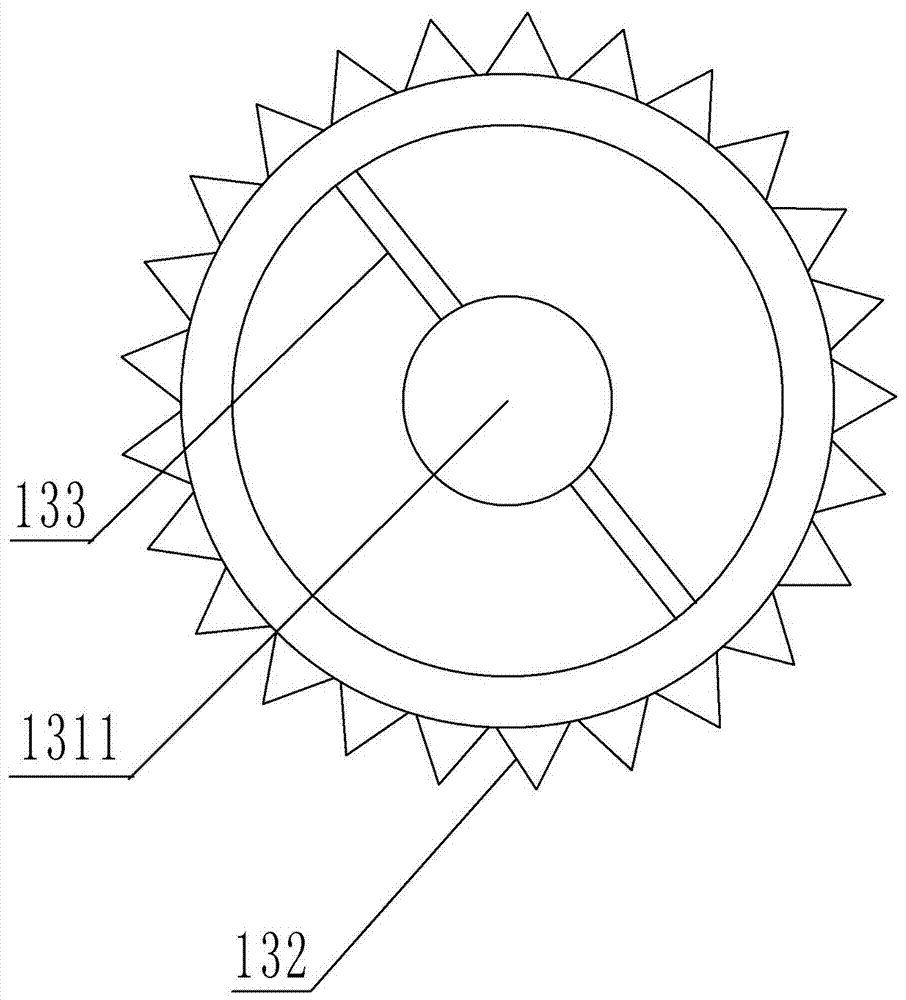

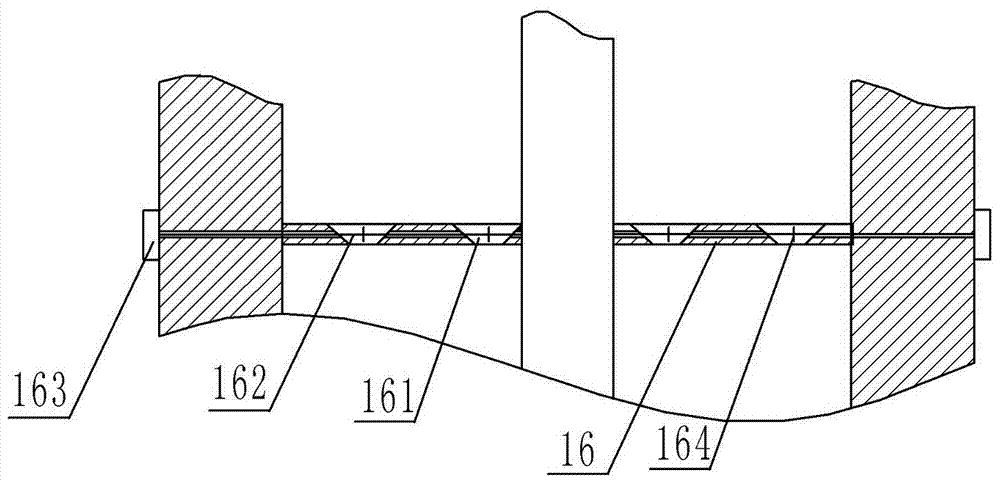

[0028] The reference signs in the accompanying drawings of the specification include: cutting barrel 1, feed hole 11, rotating shaft 12, motor 121, driving gear 122, discharge hole 13, blade 131, fixed shaft 1311, outer ring gear 132, connecting rod 133, Sieve basket 14, cutter 15, knife rest 151, horizontal blade 152, vertical blade 153, stirring rod 154, dividing plate 16, extruding hole 161, dial shaft 162, rotary button 163, driving rod 164, stirring rod 17, Pressing plate 18, cover 19.

[0029] Such as figure 1 with figure 2As shown, the silk sugar mixer includes a closed cutting barrel 1, and the upper part of the cutting barrel 1 is inclined to be provided with a feed hole 11; The upper end is connected with motor 121; The bottom surface of the cutting barrel 1 is provided with a discharge hole 13, and a spiral blade 131 is connected with rotation in the disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com