An embroidery machine and its cloth rolling frame

A technology of cloth rolling and cloth rolling roller, which is applied in the field of embroidery machines, which can solve the problems of pattern deformation, overall aesthetic impact, and inability to complete tension, etc., to achieve the effect of convenient connection, ensuring aesthetics and quality, and avoiding low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

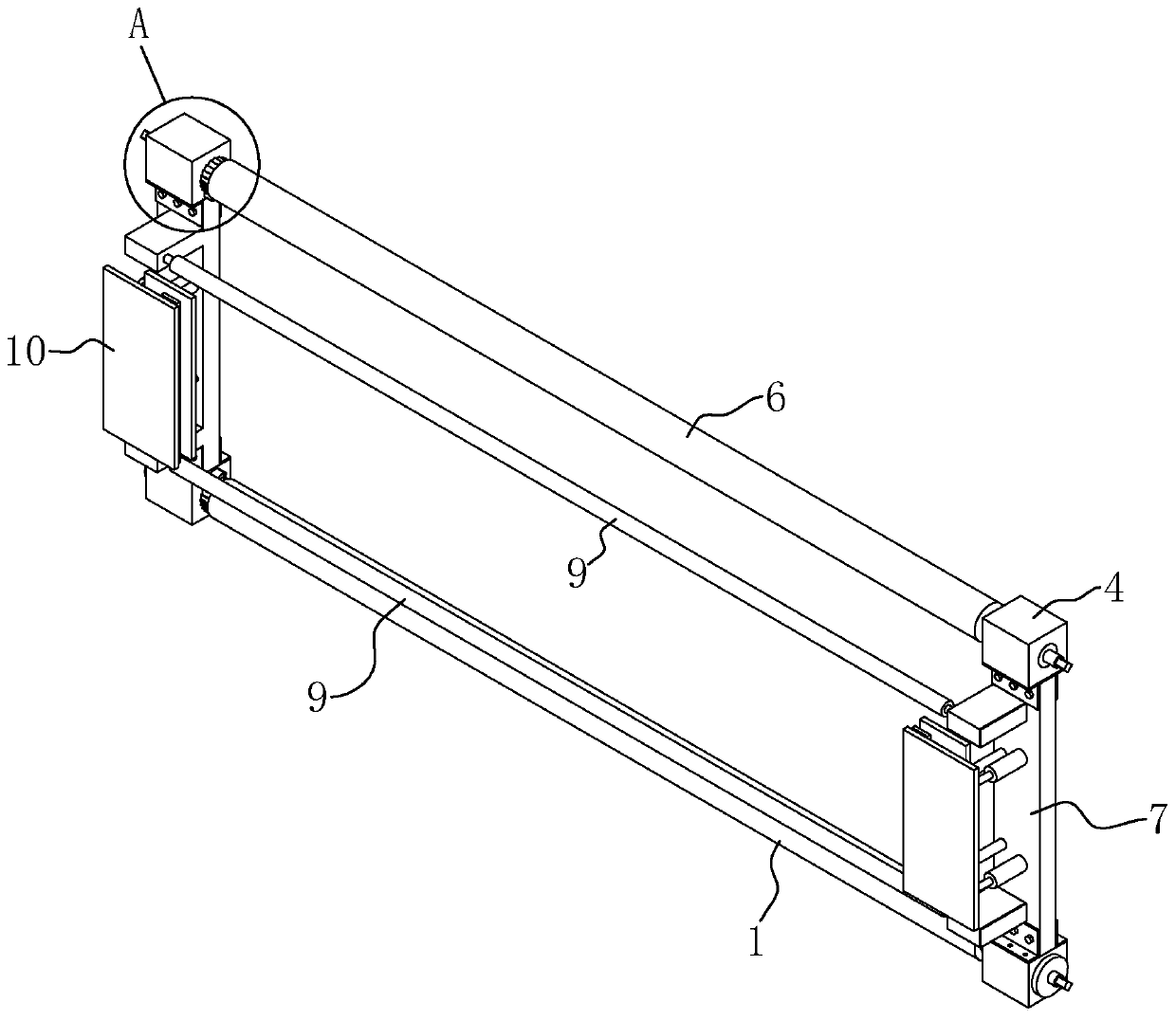

[0047] Embodiment 1: a kind of cloth rolling frame, such as figure 1 As shown, it includes: a winding roller 6, a cloth rolling roller 1, and two poles, the two poles connect the winding roller 6 and the cloth rolling roller 1 to form a frame structure, and the cloth rolling roller 1 is arranged on the winding roller 6 Carry out the conveyance of base cloth from cloth winding roller 1 to winding roller 6 below.

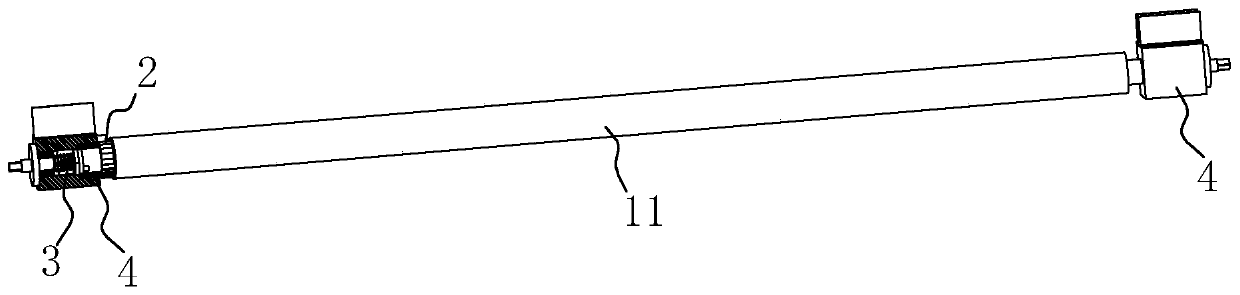

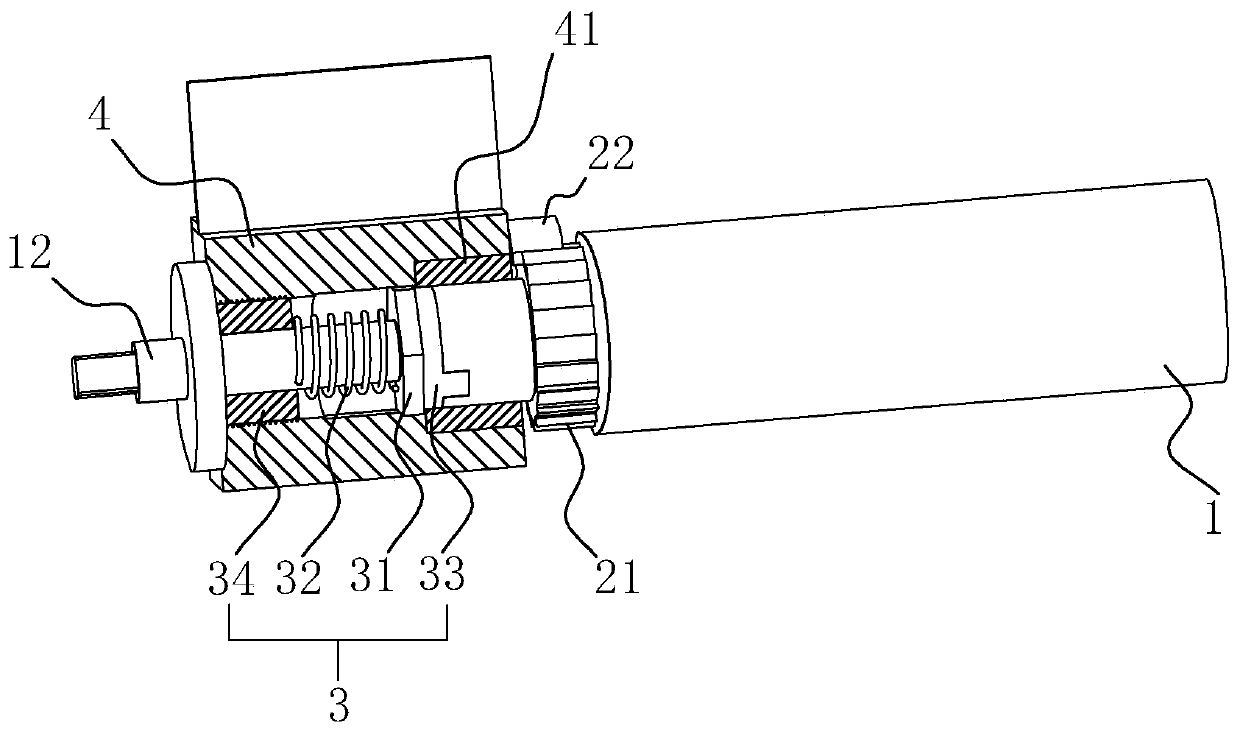

[0048] refer to figure 2 and image 3 The cloth rolling roller 1 includes a roller shaft 11, a pawl mechanism 2 and a damping mechanism 3. The pawl mechanism 2 is one in number and is arranged at one end of the roller shaft 11. The pawl mechanism 2 includes a ratchet 21 and a pawl 22. The ratchet 21 is fixed on the roller shaft 11; two damping mechanisms 3 are arranged on the two ends of the roller shaft 11 respectively.

[0049] Such as image 3 As shown, the end of the roller shaft 11 is rotatably connected to a sliding block 4 through a bearing 41, and an inse...

Embodiment 2

[0059] Embodiment 2: An embroidery machine, on which the cloth rolling frame in the embodiment is arranged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com