Anti-shift transverse H-shaped beam, self-prestress transverse H-shaped beam and self-prestress span bridge

An I-beam and prestressing technology, applied in joists, girders, trusses, etc., can solve the problems of I-beam staggering, insufficient bearing capacity, etc., to improve bearing capacity, corrosion resistance and durability. The effect of low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

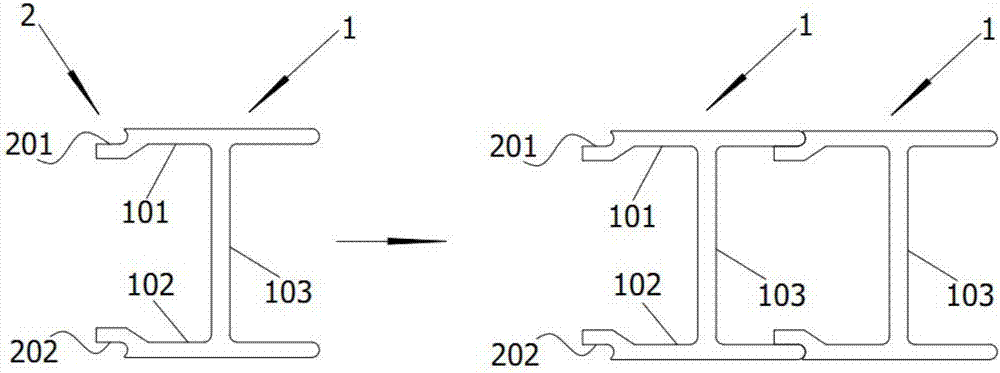

[0046] figure 1 A cross-sectional view of the anti-misalignment I-beam provided by Embodiment 1 of the present invention. Such as figure 1 As shown, the locking slot 2 includes a first locking slot 201 and a second locking slot 202 . When the profile body 1 is cut transversely, the first locking groove 201 is located on the upper surface of the left end of the upper wing 101 , and the second locking groove 202 is located on the lower surface of the left end of the lower wing 102 . In this embodiment, the first slot 201 and the second slot 202 with different positions, when a plurality of anti-slip I-beams are spliced in parallel, any anti-slip I-beam can prevent adjacent anti-slip I-beams The beam moves up and down. Since the first slot 201 and the second slot 202 are arranged on the same side of the I-beam, the I-beam presents a horizontally symmetrical structure, and the center of gravity is relatively stable for easy transportation.

Embodiment 2

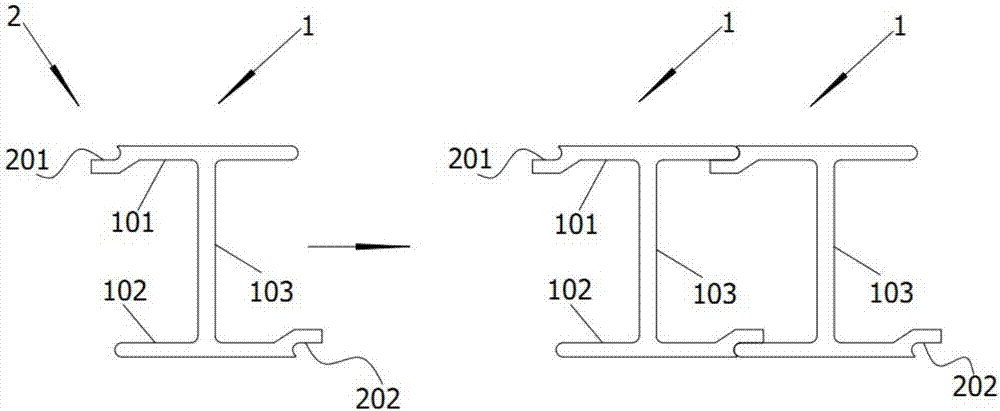

[0048] figure 2 A cross-sectional view of the anti-misalignment I-beam provided by Embodiment 2 of the present invention. Such as figure 2 As shown, the locking slot 2 includes a first locking slot 201 and a second locking slot 202 . When the profile body 1 is cut transversely, the first locking groove 201 is located on the upper surface of the left end of the upper wing 101 , and the second locking groove 202 is located on the lower surface of the right end of the lower wing 102 . In this embodiment, similarly, the first card slot 201 and the second card slot 202 with different positions, when multiple anti-stagger I-beams are spliced in parallel, any one anti-stagger I-beam can prevent adjacent anti-stagger I-beams Stagger the I-beam up and down. However, since the first clamping slot 201 and the second clamping slot 202 are arranged on different sides of the I-beam, a single I-beam is more evenly subjected to displacement force.

Embodiment 3

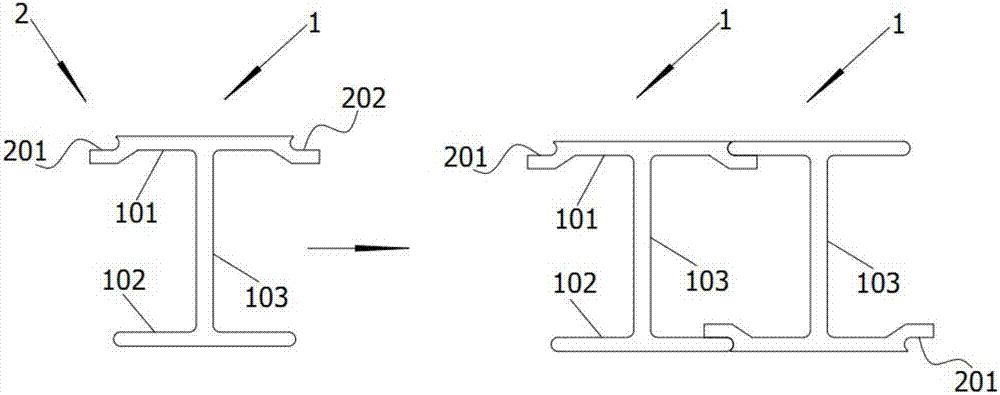

[0050] image 3 A sectional view of the anti-misalignment I-beam provided by Embodiment 3 of the present invention. Such as image 3 As shown, the locking slot 2 includes a first locking slot 201 and a second locking slot 202 . When the profile body 1 is cut transversely, the first locking groove 201 is located on the upper surface of the left end of the upper wing 101 , and the second locking groove 202 is located on the upper surface of the right end of the upper wing 101 . In this embodiment, similarly, the first card slot 201 and the second card slot 202 with different positions, when multiple anti-stagger I-beams are spliced in parallel, any one anti-stagger I-beam can prevent adjacent anti-stagger I-beams Stagger the I-beam up and down. Since the first draw-in slot 201 and the second draw-in slot 202 are both arranged on the upper wing 101 of the I-beam, the structure of the lower wing 102 remains flat, which is convenient for transportation and storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com