Multi-stage hydraulic pressurizer based on mechanical device

A mechanical device and hydraulic pressurization technology, applied in the direction of drill pipe, casing, drill pipe, etc., can solve the problems of easily damaged nozzles, difficult WOB transmission, easy to get stuck, etc., to achieve long service life and improve drilling stability. , the effect of reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

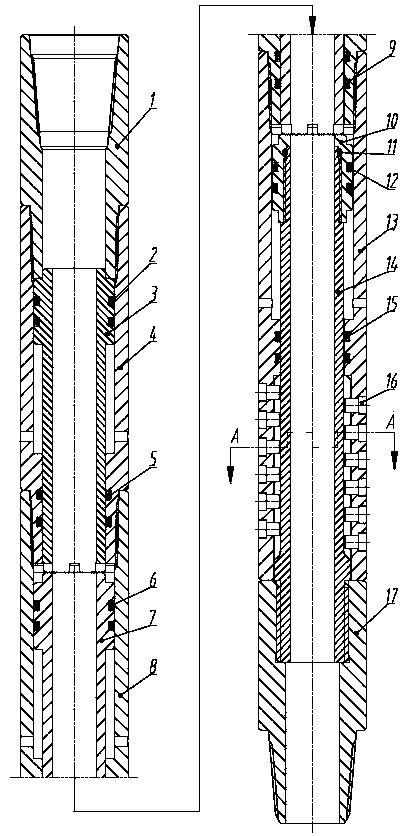

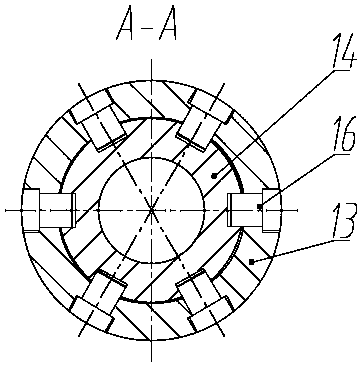

[0014] Below in conjunction with figure, the present invention will be further described:

[0015] According to the drawings, the multi-stage hydraulic pressurizer based on mechanical device is composed of an upper joint 1, a seal ring a2, a three-stage piston 3, a three-stage piston cylinder 4, a seal ring b5, a seal ring c6, a two-stage Composed of piston 7, secondary piston cylinder 8, sealing ring d9, main piston 10, sealing ring e11, sealing ring f12, main piston cylinder 13, main piston rod 14, sealing ring g15, roller 16 and lower joint 17, its characteristics That is: the three-stage piston cylinder 4 is connected to the lower end of the upper joint through threads, and the seal ring a2, the three-stage piston 3, and the seal ring b5 are sequentially installed inside the three-stage piston cylinder 4; then the seal ring c6, the two-stage piston 7 , sealing ring d9 is installed in the secondary piston cylinder 8; the main piston cylinder 13 is located between the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com