Patents

Literature

42results about How to "Improved drilling stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

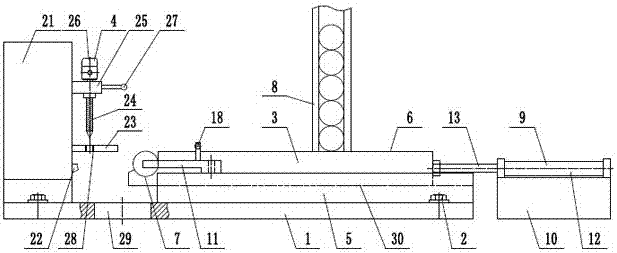

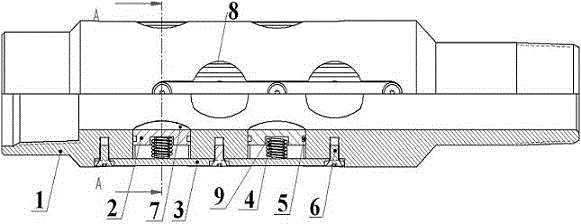

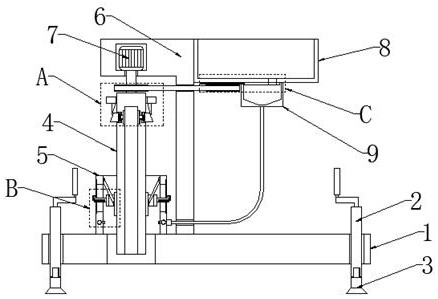

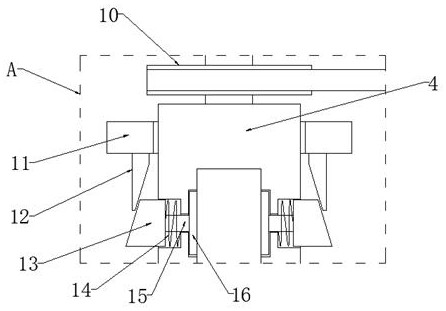

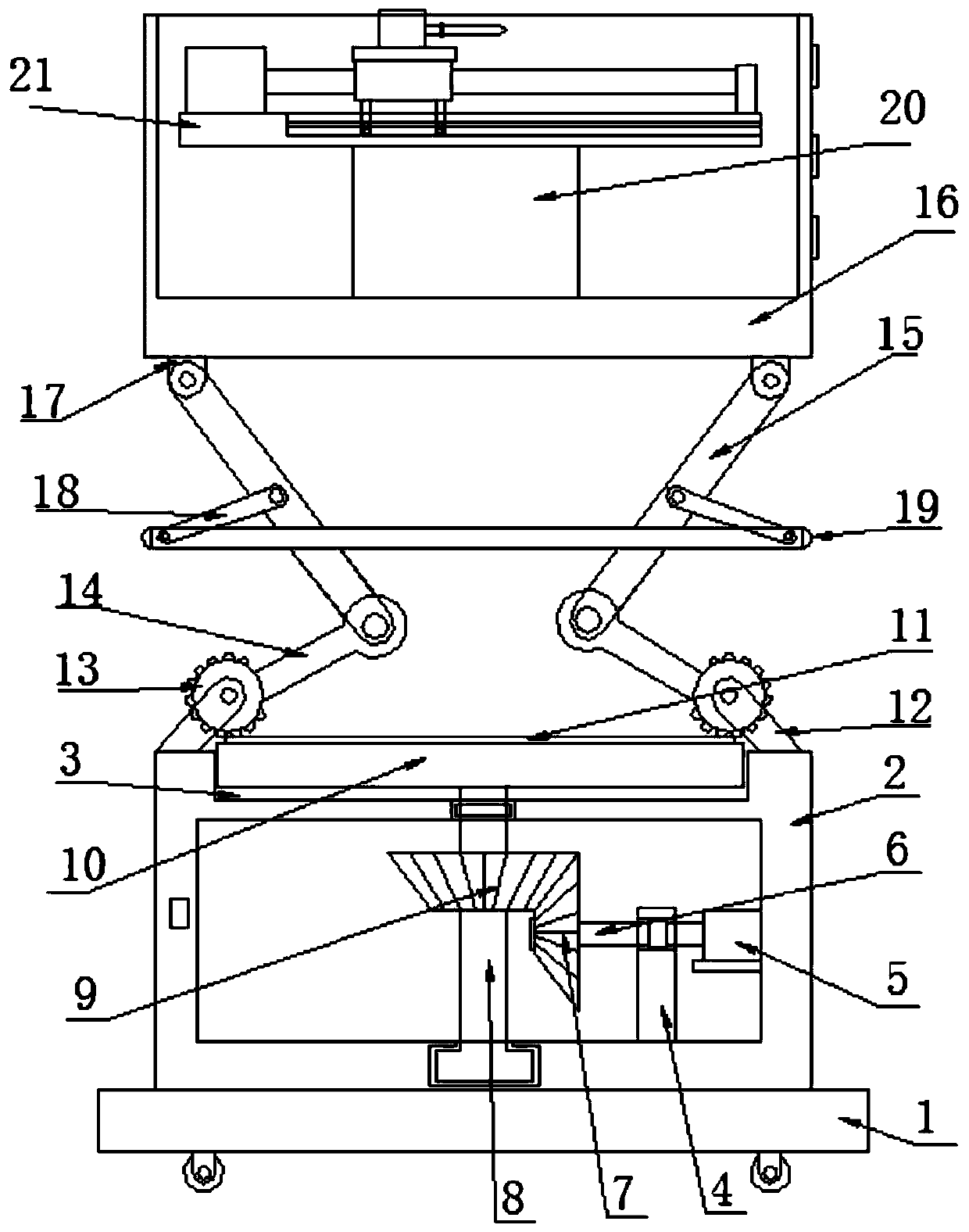

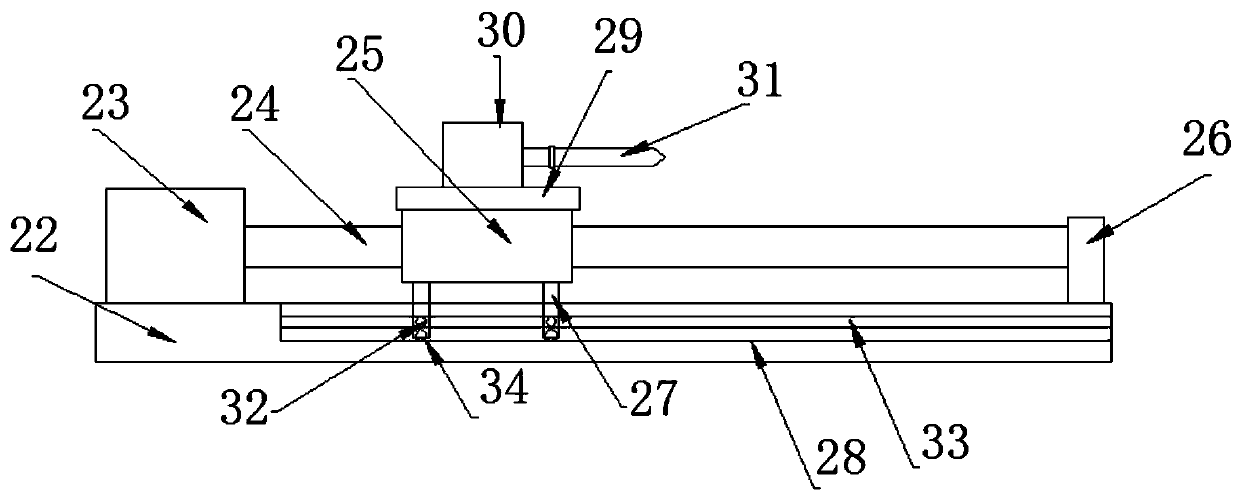

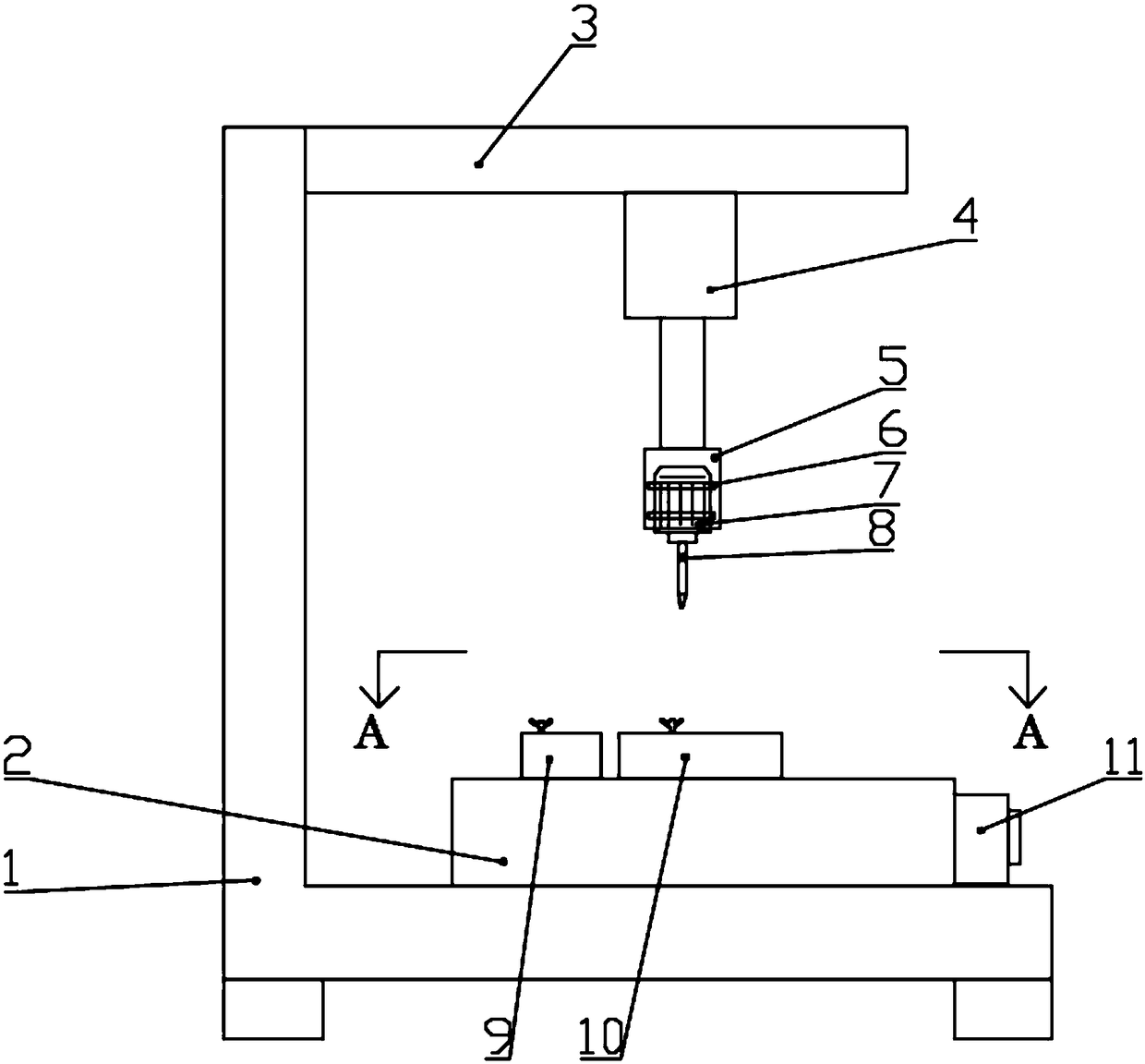

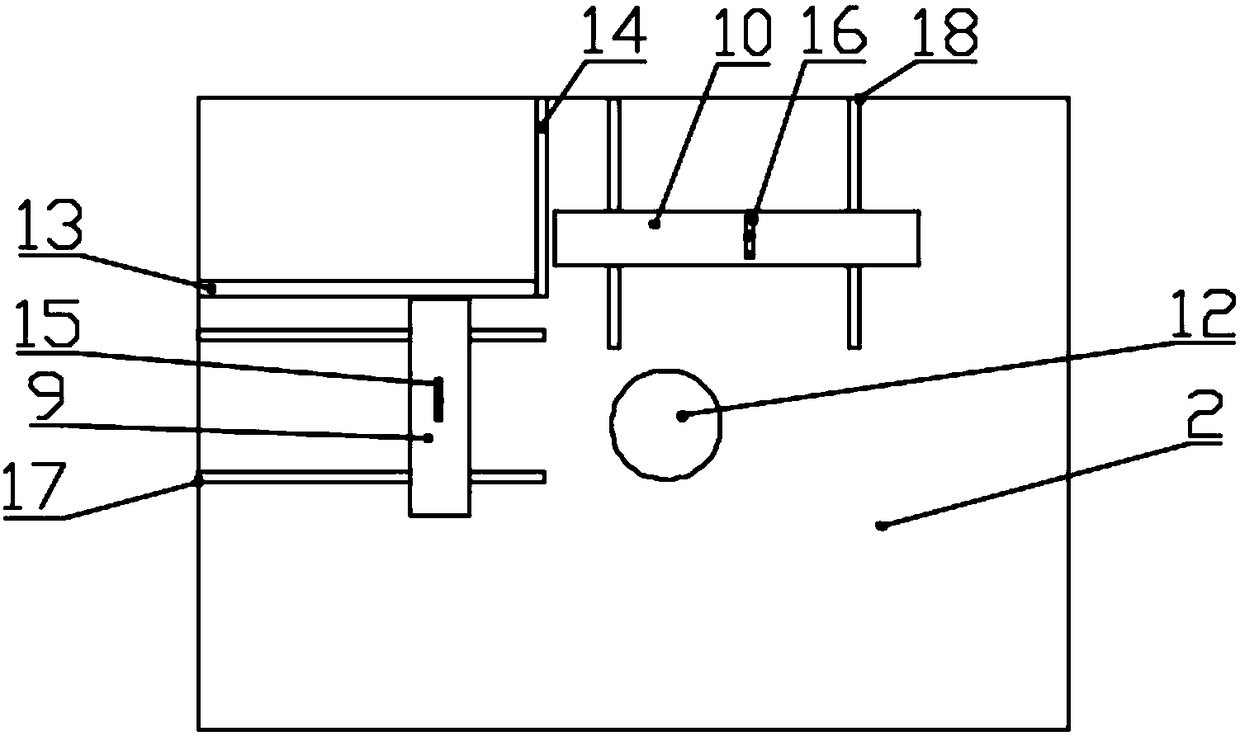

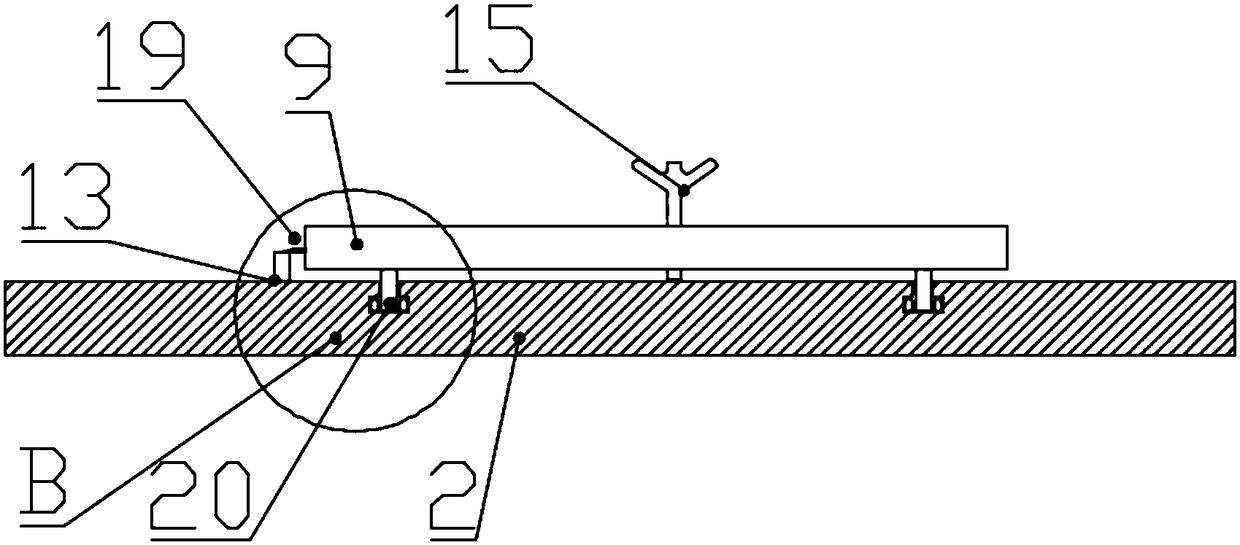

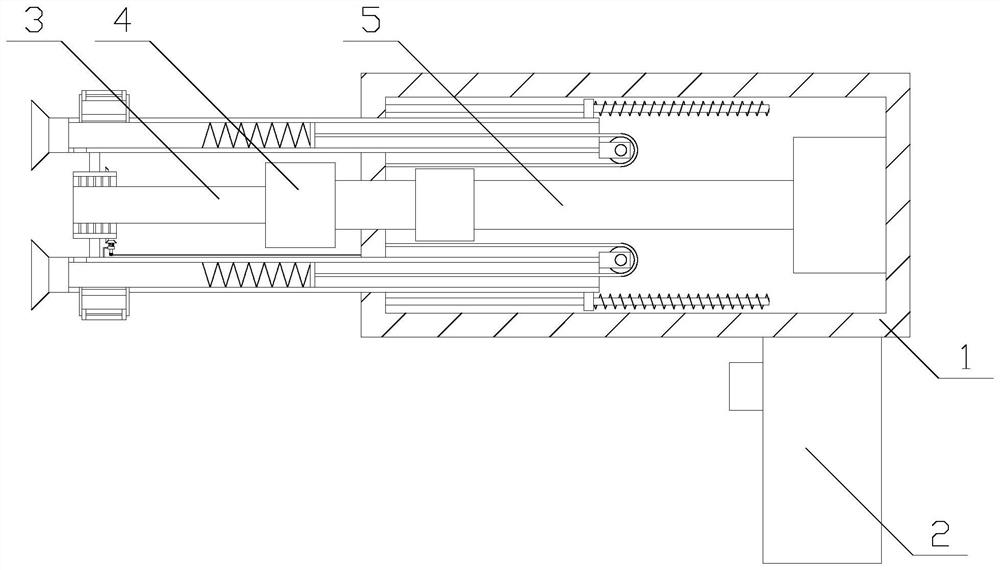

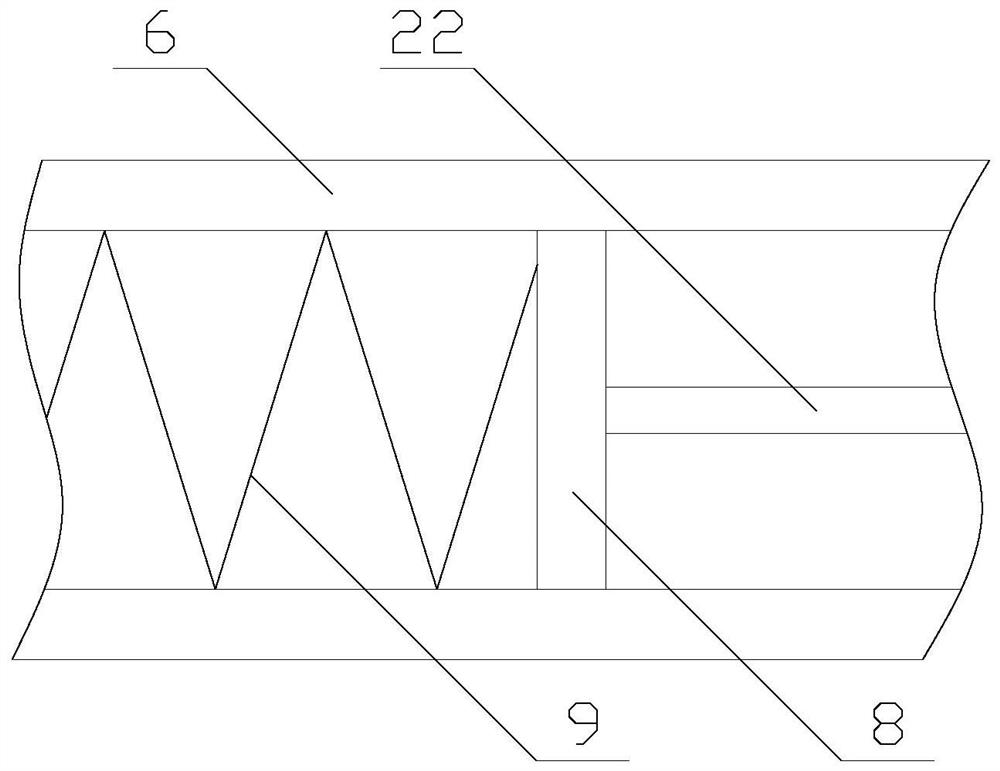

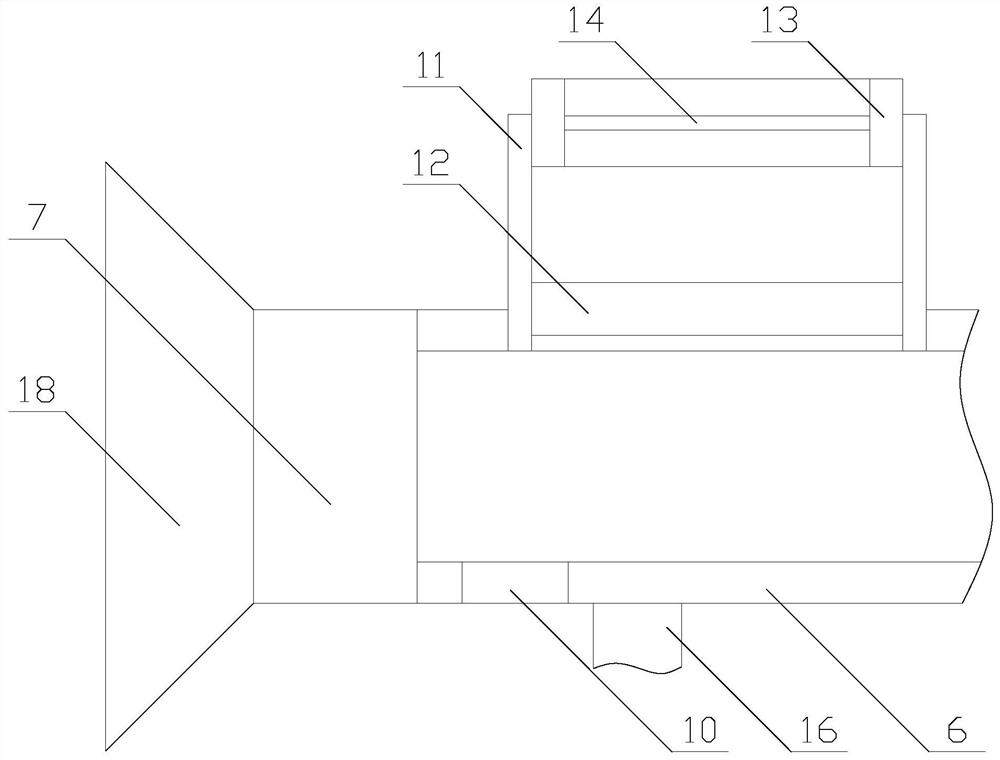

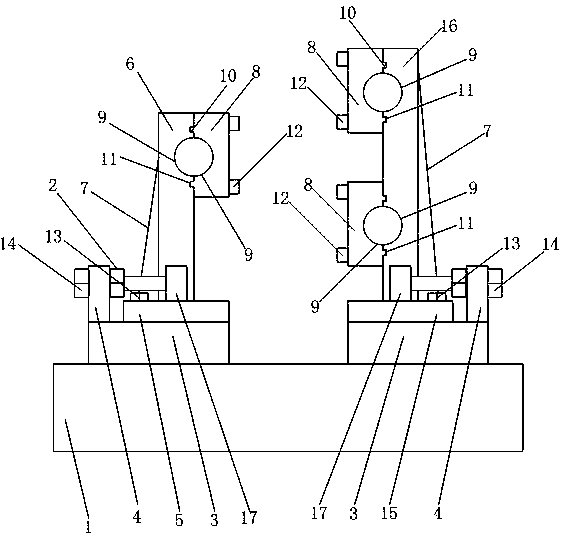

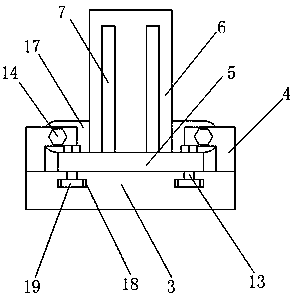

Cylindrical workpiece drilling device

ActiveCN107127369AImprove fitEasy clampingDrilling/boring measurement devicesMetal working apparatusSlide plateEngineering

The invention provides a cylindrical workpiece drilling device and belongs to the technical field of machining. The cylindrical workpiece drilling device comprises a feeding and discharging mechanism and a drilling mechanism. A feeding sliding plate of the feeding and discharging mechanism is arranged on a guiding seat in a horizontal sliding mode; a bearing groove is formed in the left end of the feeding sliding plate; a material way is located on the upper portion of the feeding sliding plate; the right end of a first pushing rod of a discharging assembly is arranged on one side of the guiding seat in a swingable mode through a first supporting pin; a second pushing rod is arranged on the other side of the guiding seat in a swingable mode through a second supporting pin; the two ends of a tension spring are connected with a first tension spring support and a second tension spring support correspondingly; a drill support of the drilling mechanism is arranged on a drilling support in a vertical sliding mode; a drill motor and a drill are coaxially connected; an operation handle is arranged on one side of the drill support; a guiding sleeve is arranged on an upper cover plate; an attaching clamping block can be attached to the left end of the bearing groove. Automatic feeding, discharging and clamping of a cylindrical workpiece are achieved, drilling machining of the cylindrical workpiece is facilitated, the structure is reasonable, and reliability is good.

Owner:爱雷德机床有限公司

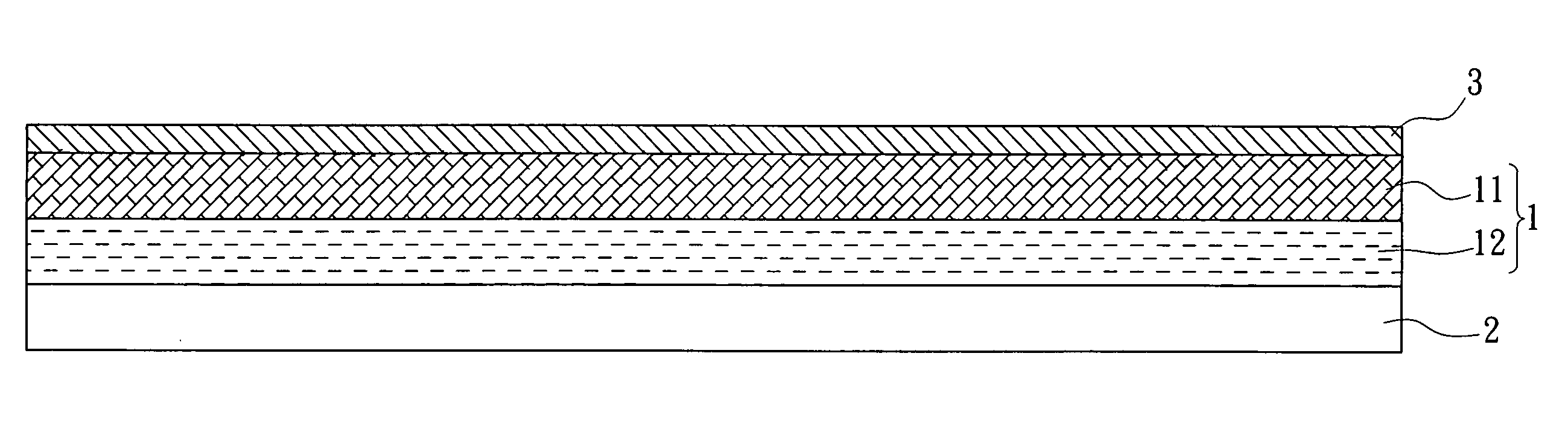

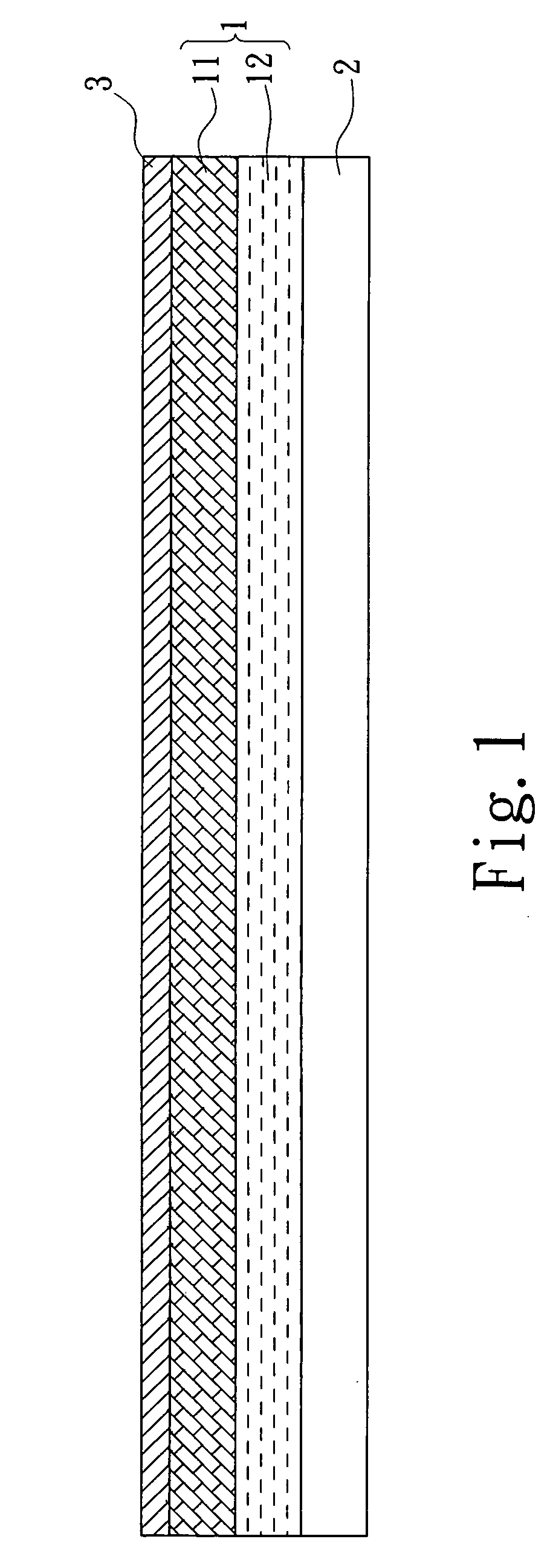

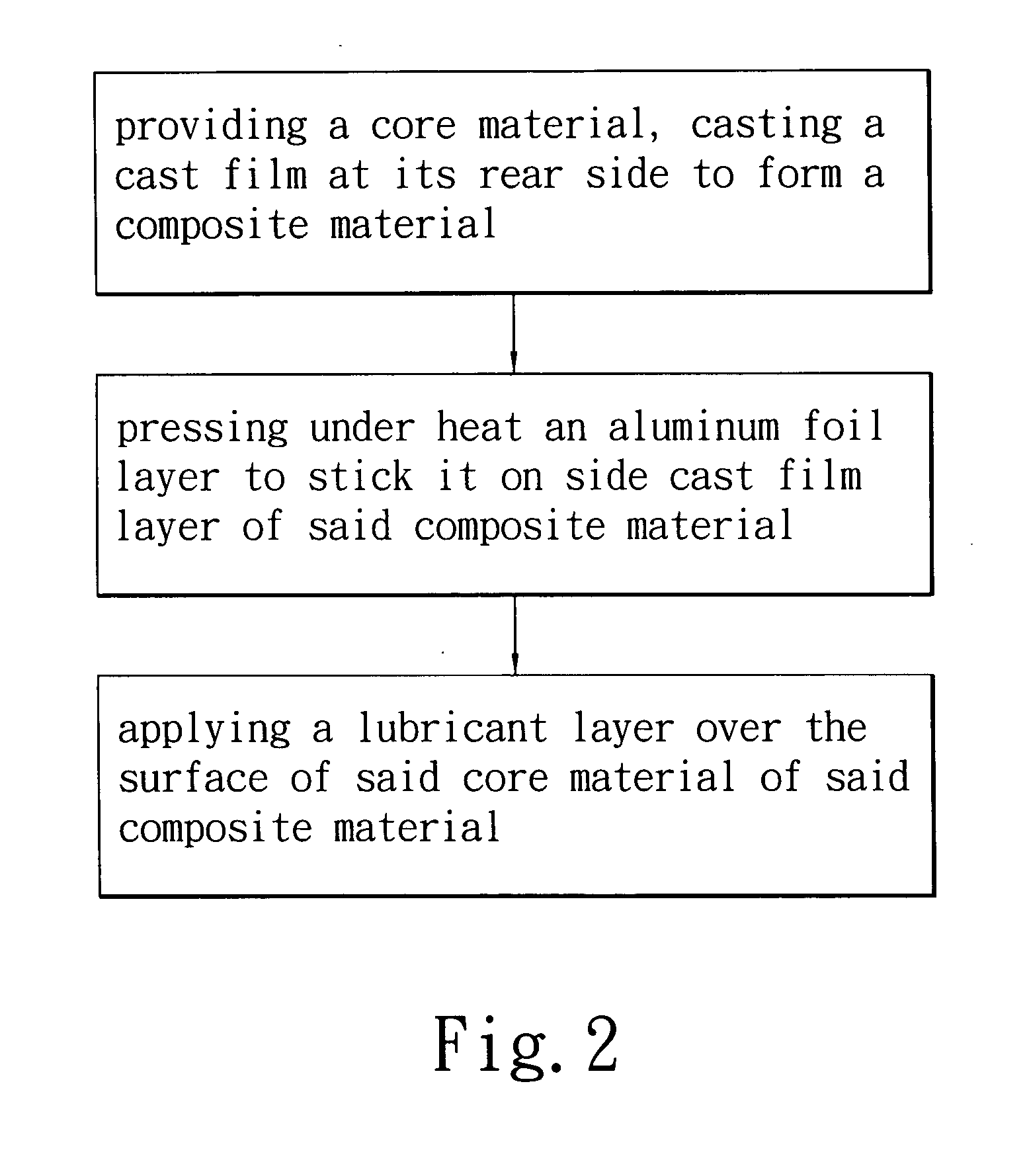

High heat-dissipating lubricant aluminum-based cover plate and production process thereof

InactiveUS20060286372A1Reduce effectively breaking incidenceImproved drilling stabilityWorkpiecesAdverse effect compensationEpoxyPHENOL LIQUID

A high heat-dissipating lubricant aluminum-based cover plate and production process thereof comprises a composite material, an aluminum foil layer and a lubricant layer, wherein said composite material is composed of a core material associated at its rear side with a cast film, said aluminum foil layer is associated by pressing under heat with said cast film of said composite material, and said lubricant layer is applied over the surface of said core material of said composite material and is one selected from nonyl phenol polyethylene glycol ether, polyethylene glycol (PEG), polyvinyl alcohol (PVA) and water soluble epoxy resin, or mixtures of equal ratio thereof; thereby, during drilling, a drilling point can be lubricated by said lubricant layer first and hence its piercing force can be buffered.

Owner:UNIPLUS ELECTRONICS

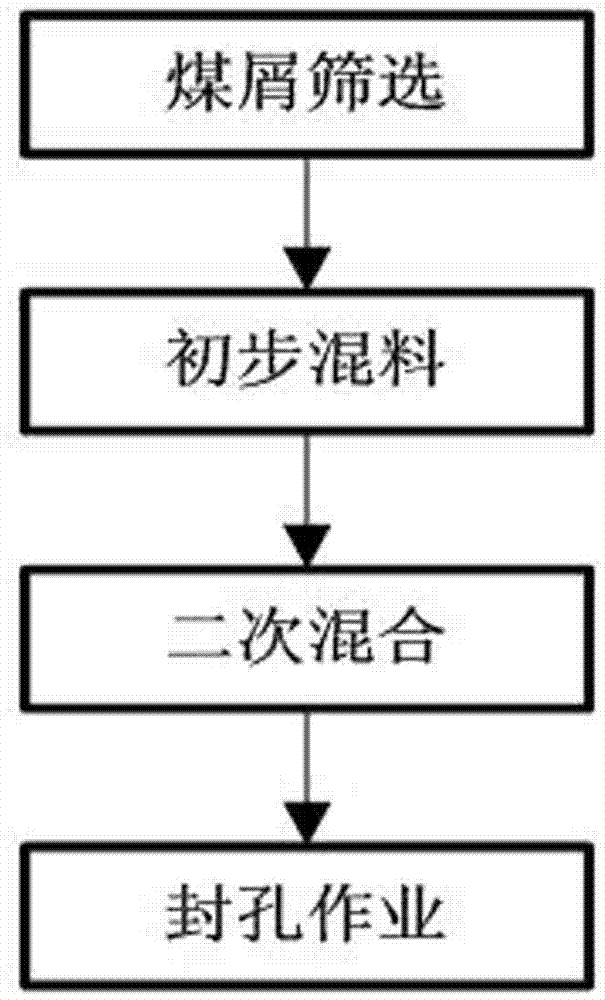

Mining coal dust based hole-sealing and grouting material, and preparation hole-sealing process

InactiveCN107011881AImprove bindingImprove compactionDrilling compositionSealing/packingAdhesiveWhole body

The invention relates to a mining coal dust based hole-sealing and grouting material. The mining coal dust based hole-sealing and grouting material consists of the following materials in parts by mass: 15.87 to 28.65 percent of coal dust, 28.65 to 31.75 percent of an adhesive, 0.48 to 0.93 percent of a crosslinking agent, 3.17 to 6.17 percent of an enhancer, 0.32 to 0.62 percent of an expanding agent, 0.14 to 0.63 percent of a flexibilizer, 0.16 to 0.57 percent of a coupling agent and the balance of water. The preparation hole-sealing process comprises four steps of screening the coal dust, mixing the materials primarily, mixing for the second time and performing hole-sealing operation. According to the grouting material, on one hand, the whole combining property of the structure, the compaction, blockage and leak blocking effects, and the weather tolerance of the grouting material are effectively improved, and on the other hand, the pulverized coal at the periphery of a drill hole can adhere to each other again to form a continuous whole body, the drilling stability is improved, the construction process of the drilling hole-sealing construction is greatly retarded while the dust pollution in the drilling construction operation field can be reduced, on-site construction operation is facilitated, the flexibility and the reliability of the drilling hole-sealing operation are improved, and wide application prospect is achieved.

Owner:HENAN POLYTECHNIC UNIV

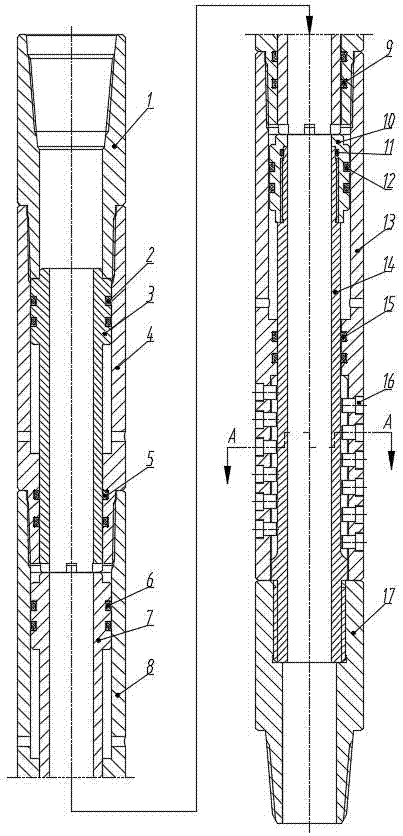

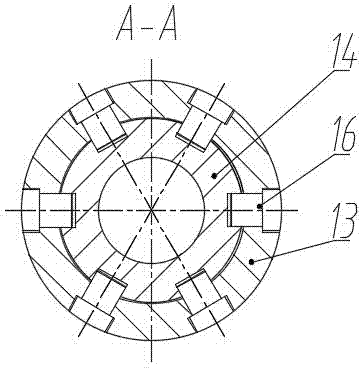

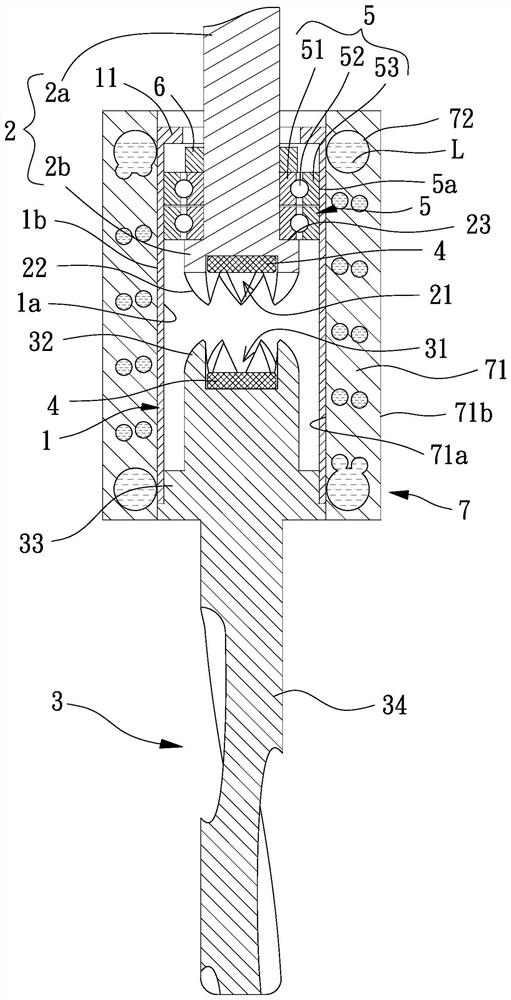

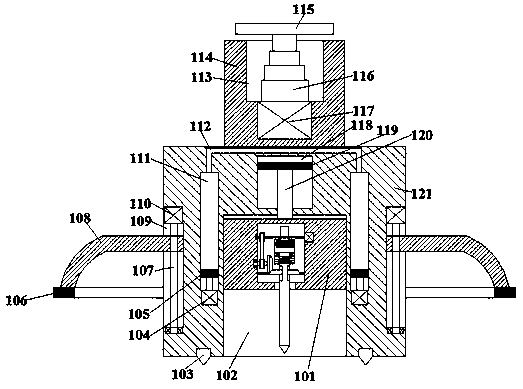

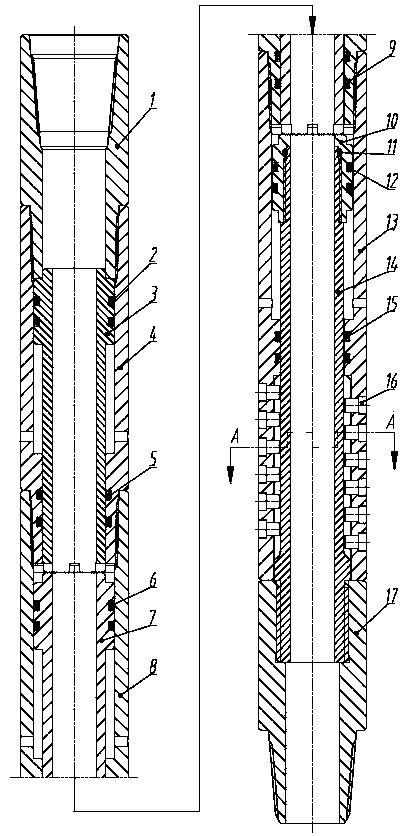

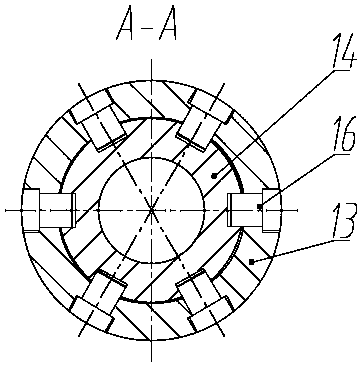

Downhole torque control tool for milling operation

InactiveCN104963639AAvoid weight-on-bit fluctuationsImprove milling efficiencyBorehole/well accessoriesControl theoryWellbore

The invention provides a downhole torque control tool for milling operation. The downhole torque control tool for the milling operation comprises a body which is a tubular body provided with through holes in the circumferential direction, each through hole is provided with a torque anchor palm which is in clearance fit with the through hole, the torque anchor palms are perpendicular to the axial direction of the body, the anchoring end of each torque anchor palm is provided with anchor teeth and a counter bore which are parallel to the axial direction of the body, a stretchable spring is arranged in each counter bore, a pressing plate is arranged at the lower ends of the stretchable springs, and the pressing plate is fixedly connected with the body; the end size of the other end of each torque anchor palm is larger than the inner diameter of the top of the corresponding through hole. According to the downhole torque control tool for the milling operation, drill pressure fluctuation brought by deformation of an operation tubular column in a shaft due to the fact that the operation tubular column bears inverted torque is effectively avoided, on the premise of not affecting the axial movement of the operation tubular column, the safety risks brought by tubular column tripping and reverse twisting of the tubular column on the shaft head are decreased, power torque output by a screw motor is stably controlled on a front section milling tool, the drilling grinding stability is improved, and the milling efficiency is improved.

Owner:PETROCHINA CO LTD

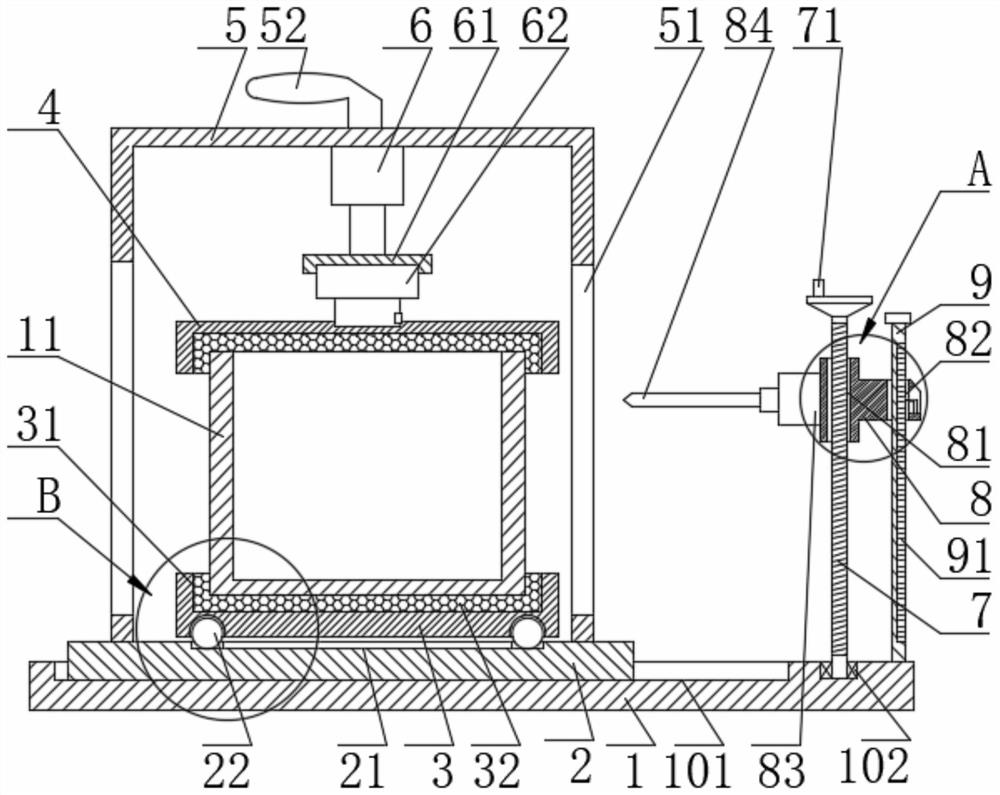

Concrete drilling and coring machine for constructional engineering quality supervision

ActiveCN112576214AEasy to take outShorten the timeConstructionsGeneral water supply conservationElectric machineryCoring

The invention discloses a concrete drilling and coring machine for constructional engineering quality supervision, and relates to the field of constructional engineering. The concrete drilling and coring machine aims at solving the problems that the coring operation of an existing drilling and coring machine during constructional engineering quality supervision is more in dust and a drilled sampleis inconvenient to take out. According to the technical scheme, the concrete drilling and coring machine comprises a bottom plate, vertically distributed threaded rods are arranged at the four corners of the bottom plate in a threaded penetrating mode, supporting legs are rotatably mounted at the bottom ends of the threaded rods, handles are fixedly connected to the top ends of the threaded rods,a mounting frame is fixedly connected to the top end of the bottom plate, and a driving motor is fixedly mounted in the mounting frame. The concrete drilling and coring machine is novel in structure,can limit and protect drill bits with different sizes, improves the drilling stability, can perform effective dust fall treatment in the drilling operation process, can conveniently take out a drilled sample after the drilling operation is completed, shortens the drilling sampling time, improves the working efficiency, and is suitable for popularization and application.

Owner:尹红文 +5

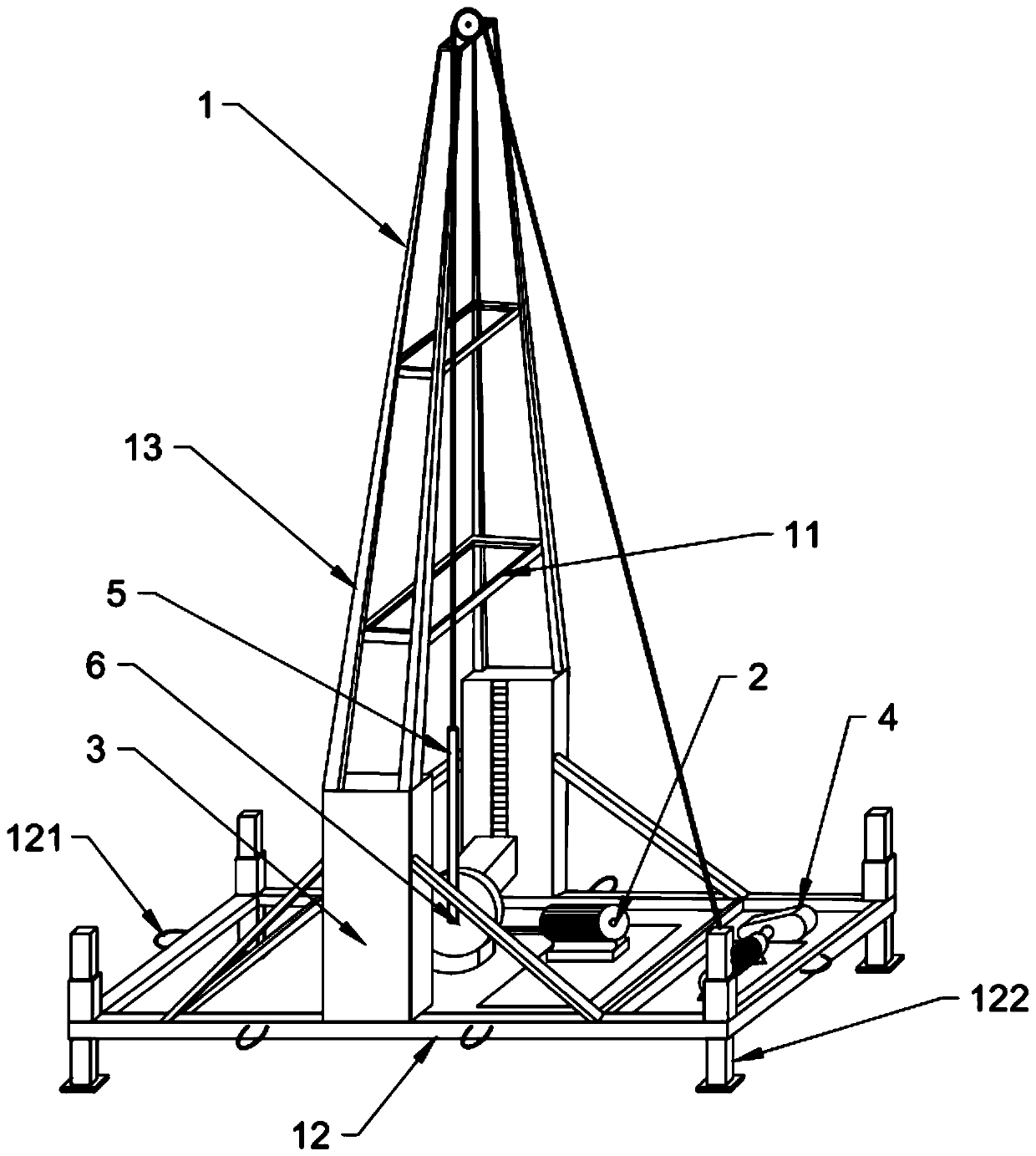

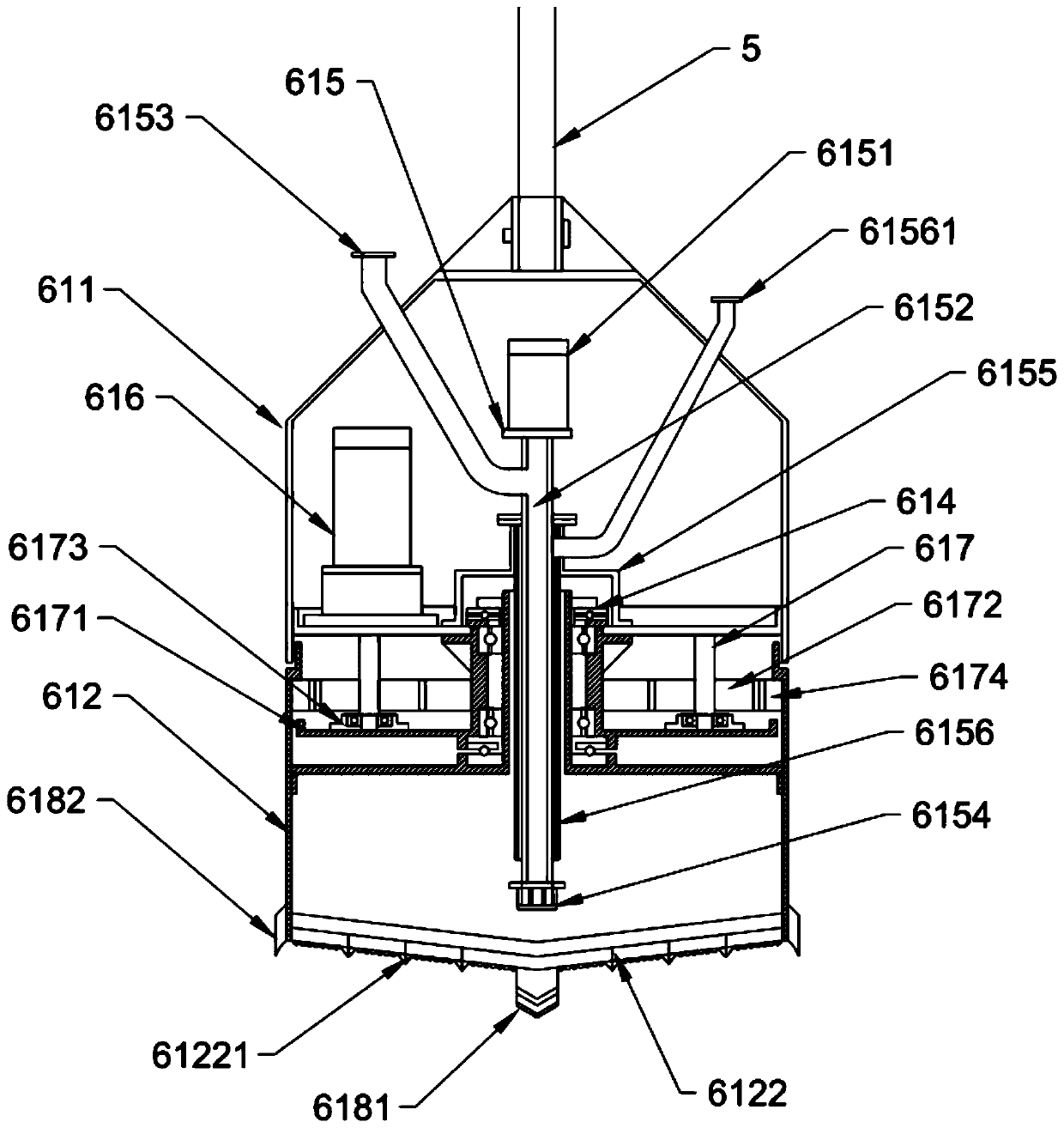

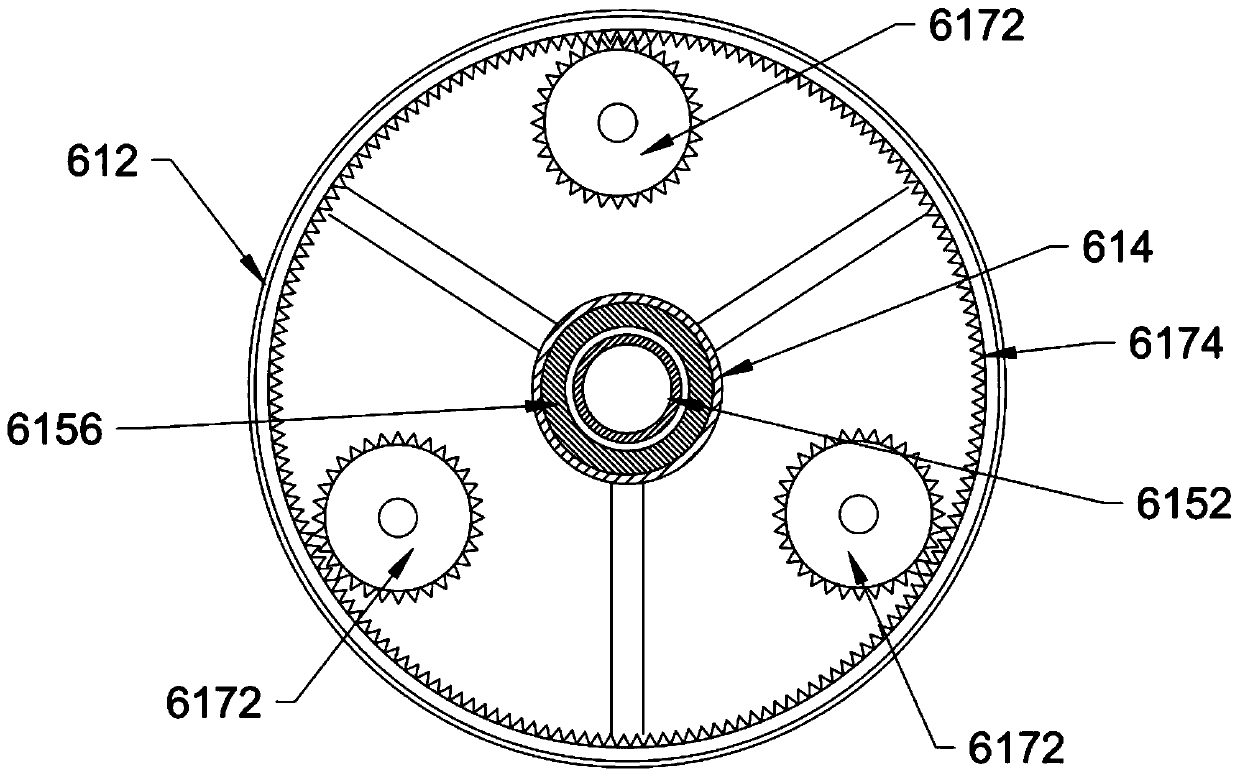

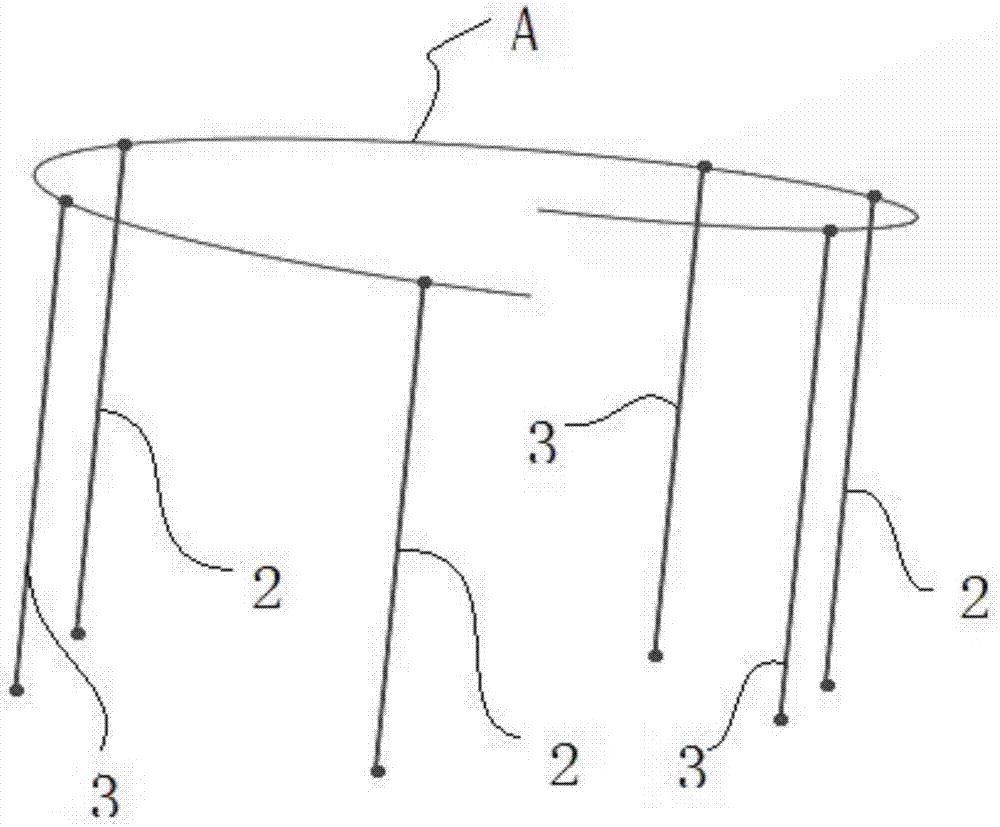

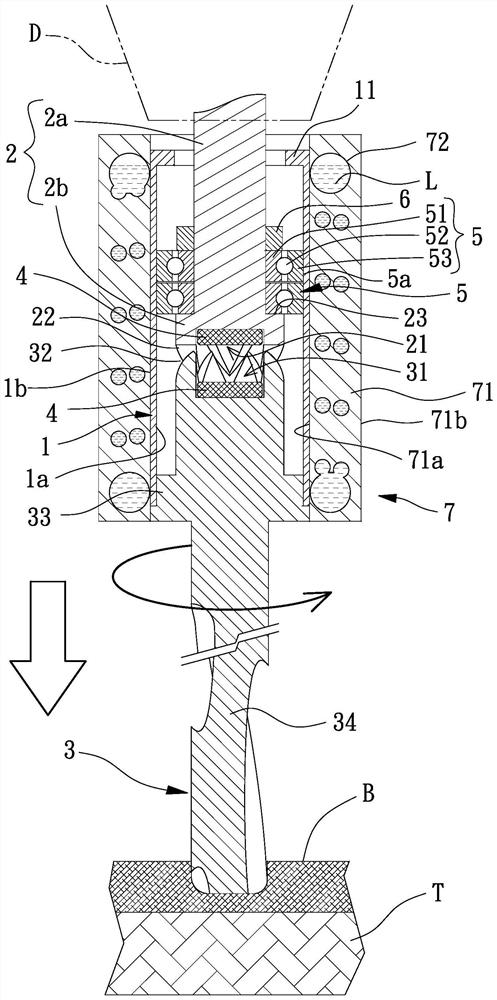

Pile foundation digging machine for building foundation engineering

PendingCN110863773AAvoid vibrationAvoid swingingEarth drilling toolsDrill bitsArchitectural engineeringWinch

The invention relates to a pile foundation digging machine for building foundation engineering. The pile foundation digging machine for building foundation engineering comprises a drill stand, a powerhead, two hydraulic vertical lifting frames, a winch, a telescopic drill pipe and a drill bit mechanism. The drill stand comprises an upper bracket ring, a lower bracket ring and diagonal struts. Thepower head, the hydraulic vertical lifting frames and the winch are arranged on the lower bracket ring, the two hydraulic vertical lifting frames are used for supporting and lifting the drill bit mechanism for the convenience of replacing the drill bit mechanism, the power head is arranged between the two hydraulic vertical lifting frames for driving a telescopic pull rod to rotate, the upper bracket ring is connected to the top ends of the hydraulic vertical lifting frames through the diagonal struts, the winch is arranged at one end of the lower bracket ring, the upper bracket ring is connected to the telescopic pull rod through a steel wire rope, and the telescopic pull rod is connected to the drill bit mechanism. The pile foundation digging machine is simple and light and convenient,low in manufacturing cost, suitable for various different pile driving environments and bore diameters, strong in chambering ability and high in drilling stability, and can lower the labor cost, avoidpotential safety hazards of a manual hole digging pile and improve the construction efficiency and the chambering efficiency greatly.

Owner:湖南鼎功岩土特种设备有限公司

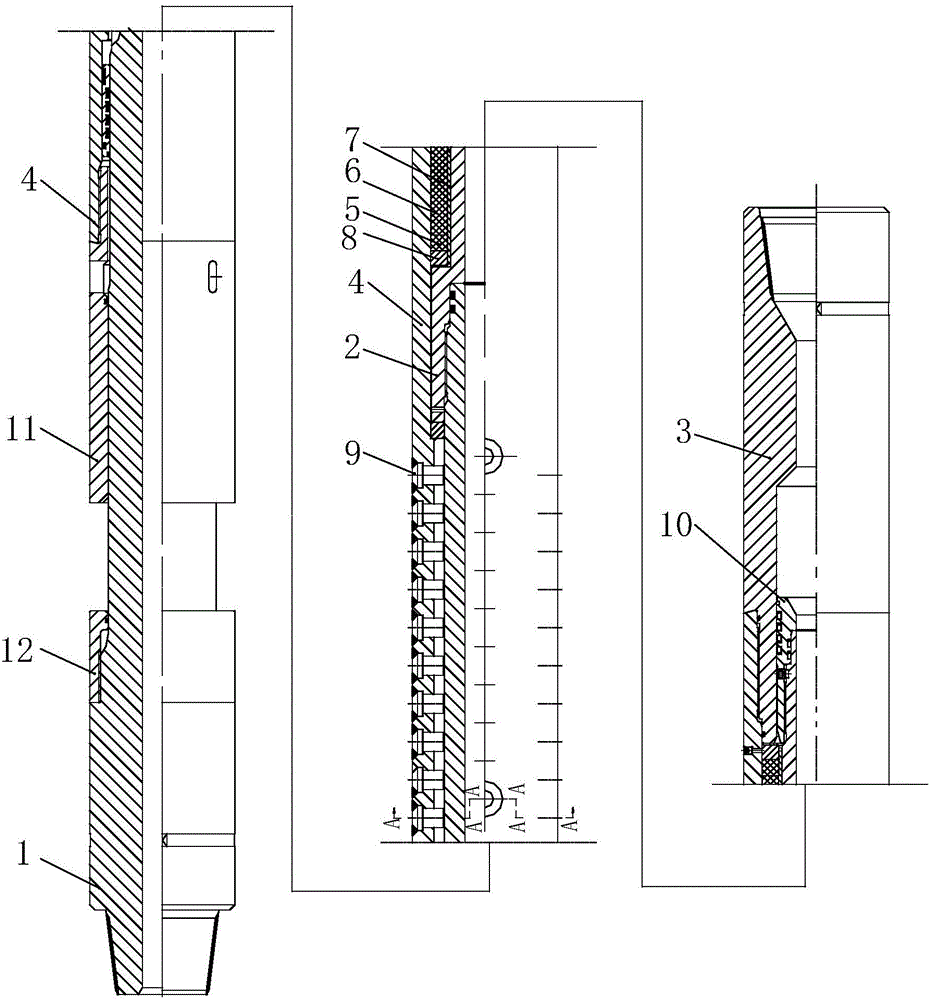

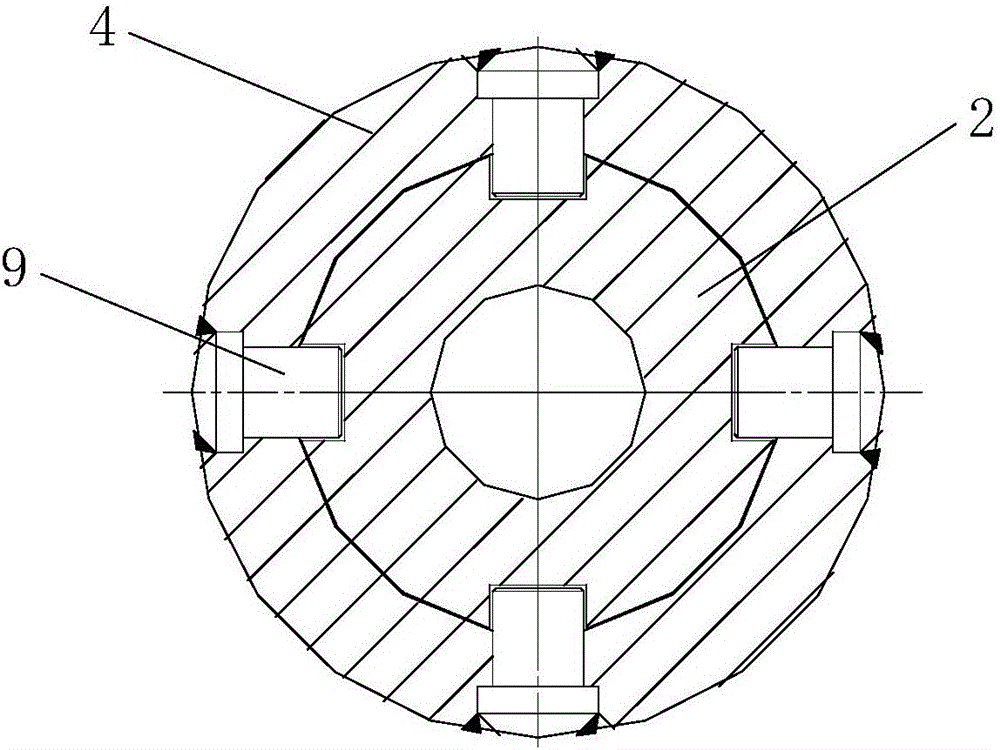

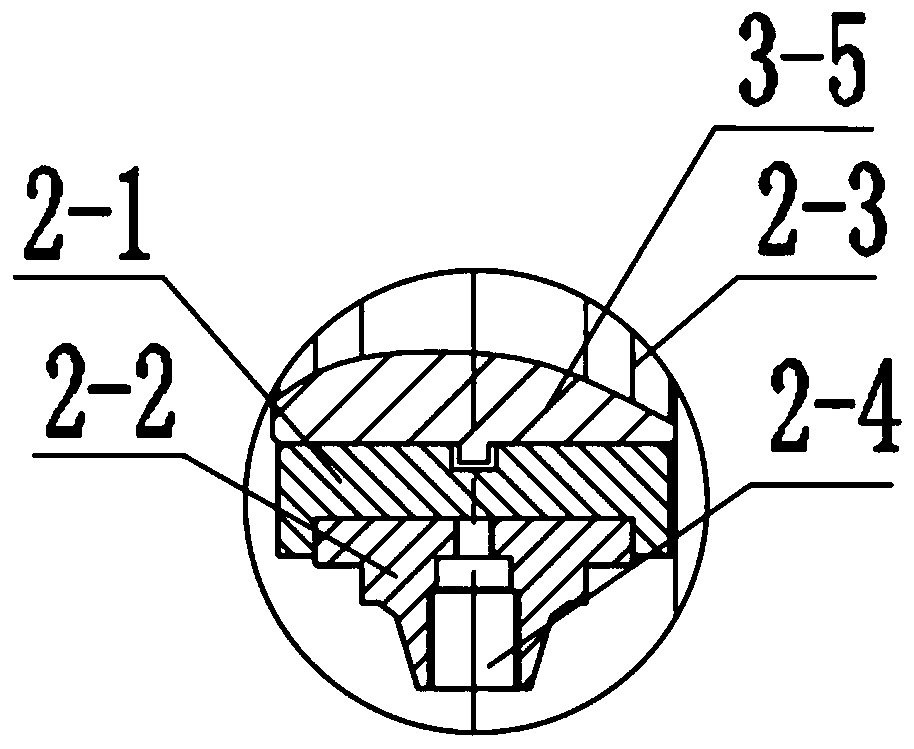

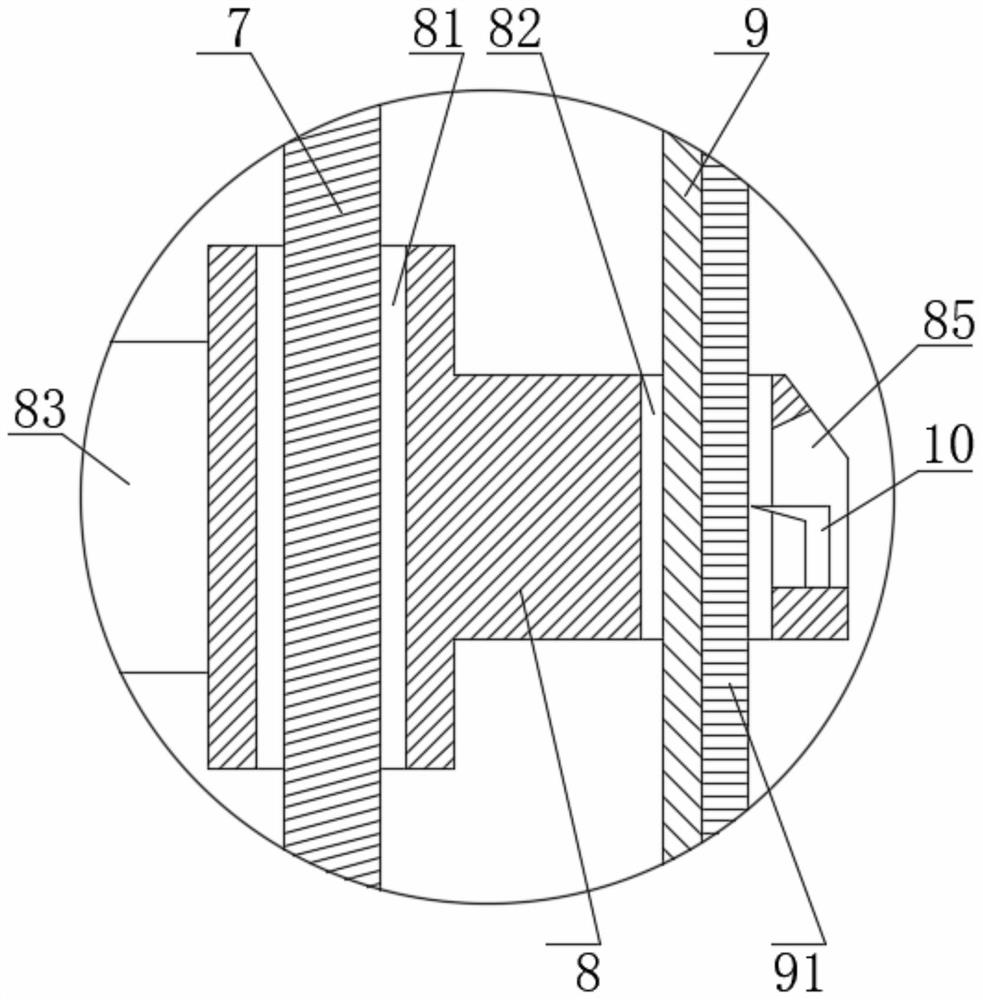

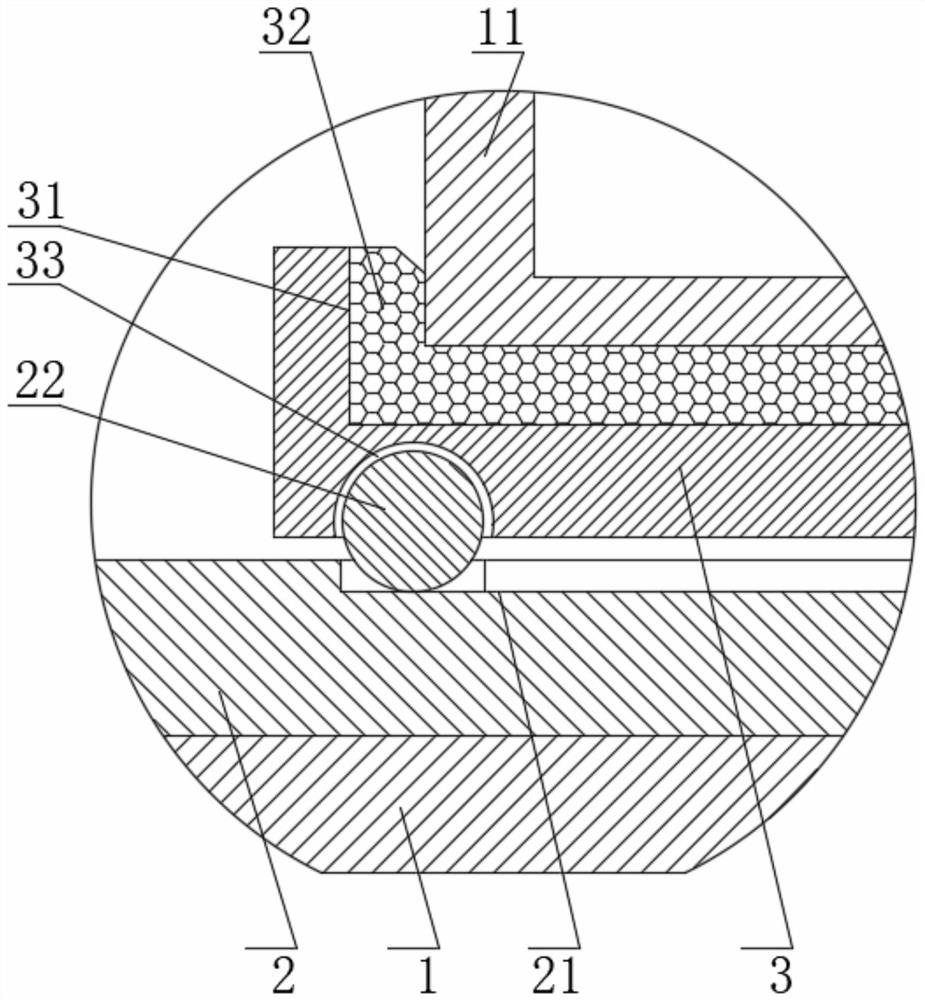

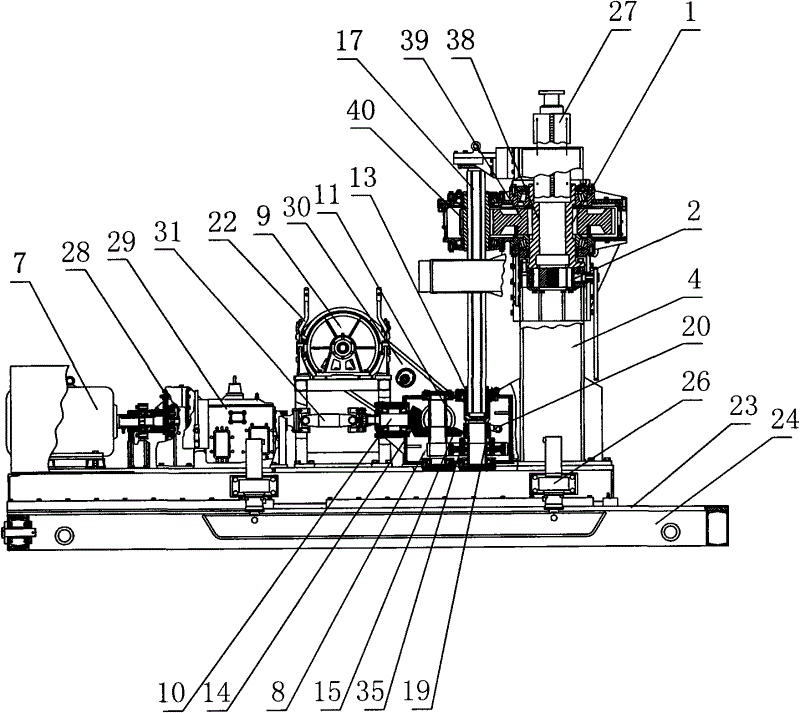

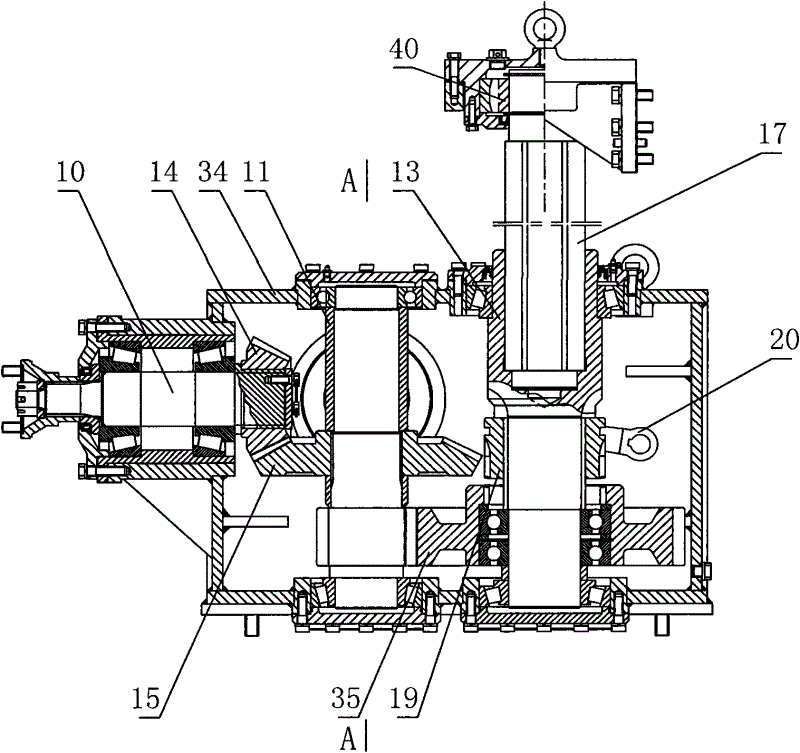

Multi-stage hydraulic pressurizer based on mechanical devices

ActiveCN107091060ASimple structureExtended service lifeDrilling rodsDrilling casingsUpper jointAxial thrust

The invention relates to a three-stage one-stroke hydraulic pressurizer applied to drilling of conventional wells, slim holes and micro-holes. The technical scheme of the three-stage one-stroke hydraulic pressurizer is that an upper joint, different stages of piston cylinders and a lower joint are connected sequentially through threads; the lower end of the upper joint of the hydraulic pressurizer is connected with a third-stage piston cylinder through threads; the third-stage piston cylinder and a second-stage piston cylinder are connected with a main piston cylinder; a third-stage piston, a second-stage piston and a main piston are mounted in the corresponding cylinder bodies respectively; the main piston cylinder and a main piston rod are flexibly connected through a roller mounted on the cylinder body and a keyway formed in the piston rod; the upper end of the main piston rod is connected with the main piston through threads, and the lower end of the main piston rod is fixed on the lower joint through threads. With adoption of the hydraulic pressurizer, mud power is converted into axial thrust, so that constant bit pressure is applied to a drill bit, the bit pressure transfer efficiency can be increased, the problems of bit jumping, backing pressure and the like are solved effectively, the service life of the drill bit is prolonged, fatigue failures of a drilling tool are reduced, and drilling efficiency is increased.

Owner:山东王晁煤电集团新能发电有限公司

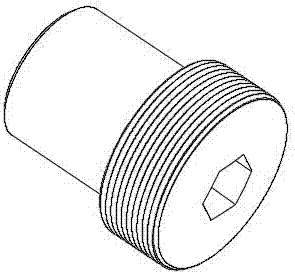

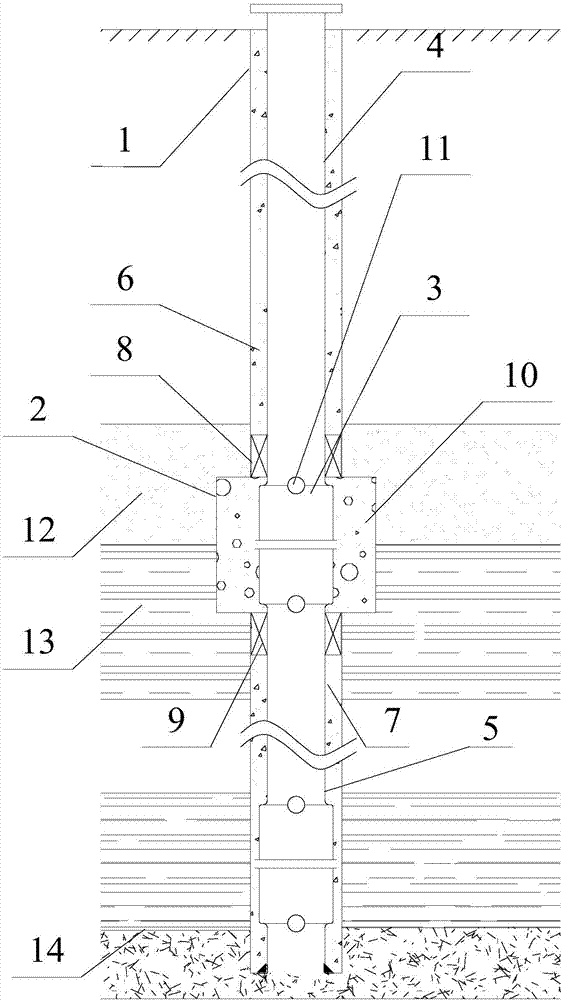

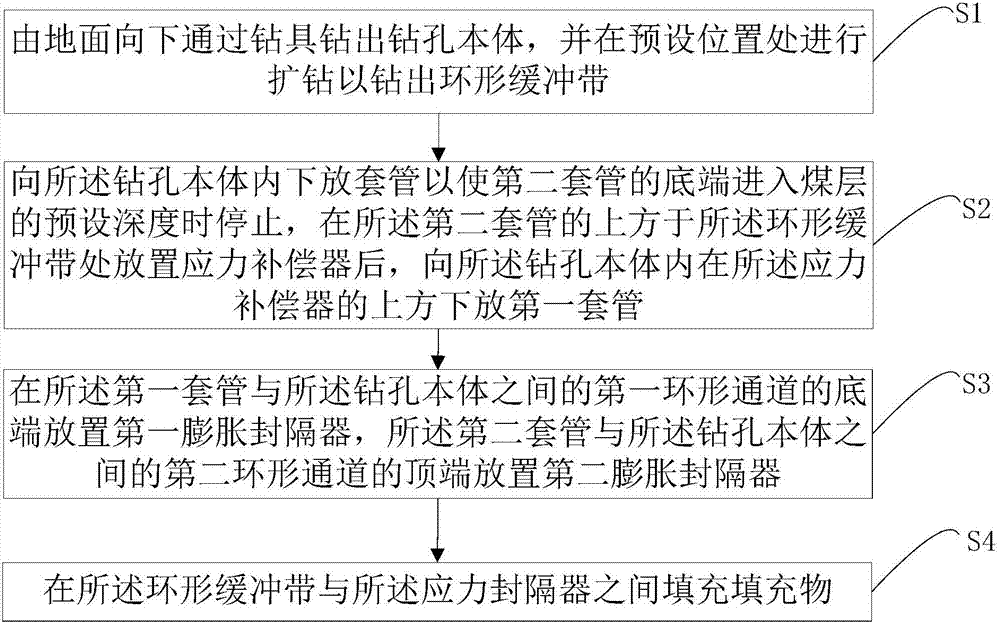

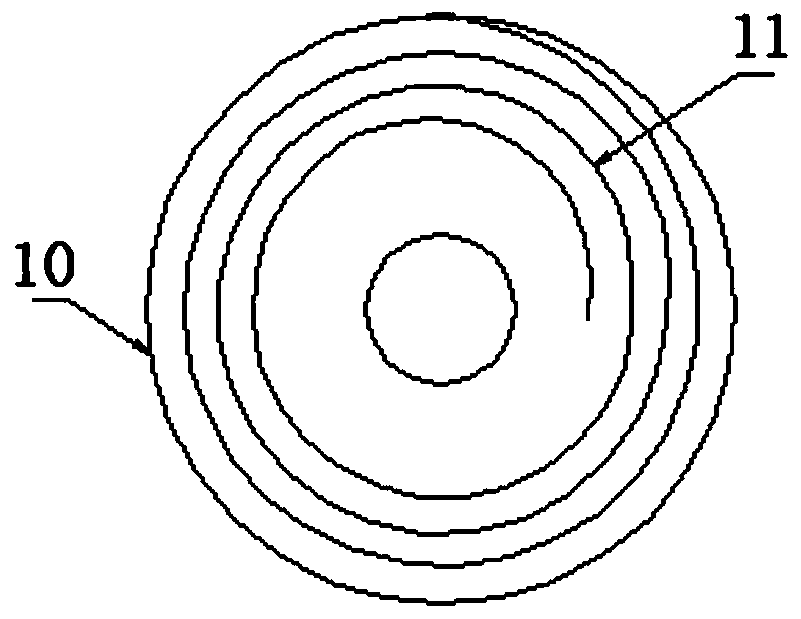

Drilling structure and construction method thereof

ActiveCN107120070AImproved drilling stabilityGasification effectDrilling rodsConstructionsDrill holeGround movement

The invention provides a drilling structure. The drilling structure comprises a drilling body, an annular buffer zone and a stress compensator, wherein the annular buffer zone is arranged on a first preset position of the drilling body, and the diameter of the annular buffer zone is bigger than the diameter of the drilling body. The stress compensator is arranged in the annular buffer zone, and a first casing pipe and a second casing pipe are correspondingly arranged at the positions, above and below the stress compensator, in the drilling body in a sleeving mode. According to the drilling structure, not only is intensity of a shear stress reduced through the arranged annular buffer zone, but also the stress compensator can be stretched to a certain length when stress exceeds the permissible value of a compensator through the arranged stress compensator, thus tensile failure to the first casing pipe and the second casing pipe from the excessive stress is compensated, stretch and shearing load caused by ground movement is counteracted by the stress compensation, the drilling is enabled to adapt to changes of rock stratum, drilling stability is improved, and the damage of drilling in the underground gasification process and further influence to coal gasification are avoided.

Owner:XINJIANG GUOLIHENG CLEAN ENERGY TECH CO LTD

Positioning drilling equipment for civil engineering buildings

ActiveCN110126098AReduce investmentImproved drilling stabilityWorking accessoriesStone-like material working toolsBevel gearRotating disc

The invention discloses positioning drilling equipment for civil engineering buildings. The positioning drilling equipment comprises a bottom plate, a supporting box is arranged at the top end of thebottom plate, a groove is formed in the top end of the supporting box, a supporting column is arranged at the bottom end inside the supporting box, a motor i is arranged on one side of the inner wallof the supporting box, an output shaft of the motor i penetrates through the supporting column and is connected with the rotating shaft, far away from the motor i, of the rotating shaft is provided with a bevel gear i, a rotating shaft is arranged in the middle of the bottom end of the supporting box, a conical gear II meshed with the bevel gear i is arranged on the rotating shaft in a sleeved mode, a rotating disc is arranged in the groove, and a threaded groove is formed in the top end of the rotating disc. The drilling device has the beneficial effects that the drilling process and the adjusting of the drilling position are effectively realized, and meanwhile, the drilling stability is improved, so that the investment of workers is reduced, the deviation of the drilling holes caused byunstable strength of workers is avoided, and misoperation of wall drilling is effectively avoided.

Owner:CCCC FOURTH HIGHWAY ENG +1

Heavy shock absorber for drilling operation

InactiveCN106050161AReduce frictionReduce connectionsDrilling rodsDrilling casingsWear resistantTorque transmission

The invention provides a heavy shock absorber for drilling operation. The heavy shock absorber comprises a mandrel, a shock absorption shaft and an upper connector which are coaxially arranged and connected in a threaded mode in sequence, and a centering sleeve is coaxially connected with the outer side of the mandrel. The heavy shock absorber further comprises a shock absorption sleeve, one end of the shock absorption sleeve is connected with the centering sleeve, and the other end of the shock absorption sleeve is connected with the upper connector; the shock absorption sleeve and the mandrel are flexibly connected through pin rollers fixed to the shock absorption sleeve and keyways formed in the mandrel; a shock absorption element is arranged between the shock absorption sleeve and the shock absorption shaft, an interval exists between the shock absorption element and the shock absorption sleeve, the shock absorption element and the shock absorption shaft are sealed through a bush, and the two ends of the shock absorption element are each provided with a set of wear-resistant ring and guide ring in direct contact with the shock absorption sleeve and the shock absorption shaft. The shock absorption sleeve and the shock absorption shaft form flexible connection through the pin rollers, the keyways and the wear-resistant rings, point contact is adopted for torque transmission, friction is reduced, torque is transmitted reasonably and effectively, and the service life is prolonged; a rubber cylinder is adopted as the shock absorption element, and the shock absorption effect is better.

Owner:周育康

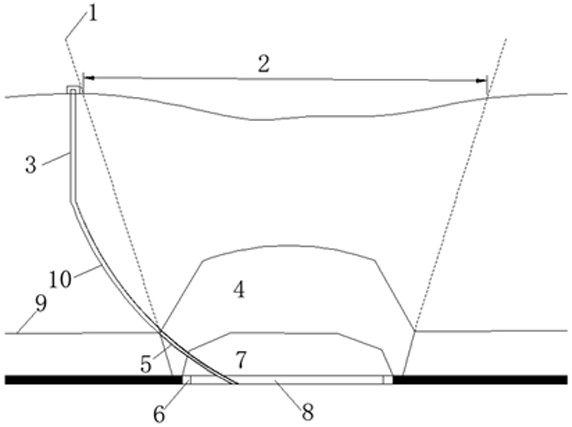

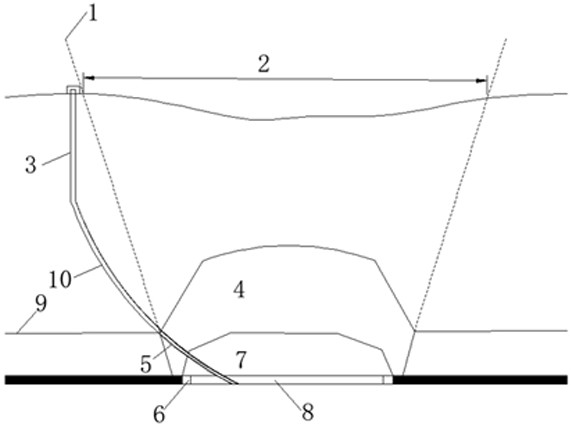

Drilling gas extraction method capable of preventing damage to ground

ActiveCN112012783AImprove the extraction effectImprove securityDrilling rodsFluid removalMining engineeringWell drilling

The invention discloses a drilling gas extraction method capable of preventing damage to the ground, and belongs to the technical field of coal mine gas extraction methods. The problems that ground vertical drilling is prone to damage due to displacement of a working face, the L-shaped drilling construction difficulty is large, and cost is high can be solved, before coal seam mining, drilling is conducted from the position 3 to 5 m away from the edge of the ground surface, of a basin, vertical downward drilling is conducted to the position 30 to 50 m away from the upper part of a fissure zone,and a vertical rigid pipe is lowered into the position; deflecting is inwards conducted in the direction away from an air return roadway by 40-60 degrees; and deflecting is started to a drilling section at the junction of the upper boundary line of a caving zone and the mining-induced stress boundary line of the air return roadway side, a flexible sleeve is lowered into the drilling section, a flexible screen pipe is lowered into a drilling section from the junction of the upper boundary line of the caving zone and the mining-induced stress boundary line of the air return roadway side to a bottom plate of the mining coal seam, and a ground wellhead is connected with a drainage pump station. The problem of damage of working face advancing to ground extraction drilling is solved to a certain extent, and the drilling stability is greatly improved.

Owner:TAIYUAN UNIV OF TECH

Method of drilling a borehole

InactiveUS6994173B2Improved drilling stabilityReduce chanceLiquid/gas jet drillingFlushingGramVolumetric Mass Density

A method for drilling a borehole employing a drilling fluid including an additive comprising a glucose derivative with pH lowering acid, buffers and surface active agents. The drilling fluid additive preferably exhibits the following properties: activity of approximately 30%–45% in water solution; pH of about 4.5 to 5.5; a light amber to clear liquid appearance and a density of approximately 1.200 grams per cubic centimeter.

Owner:ACT TECH

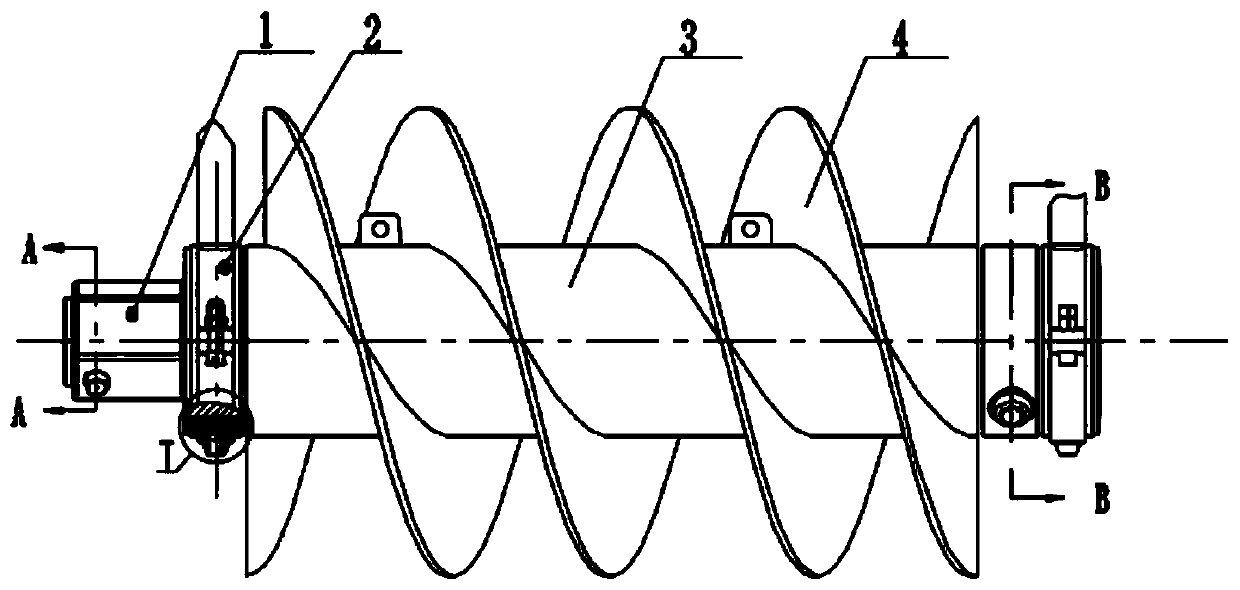

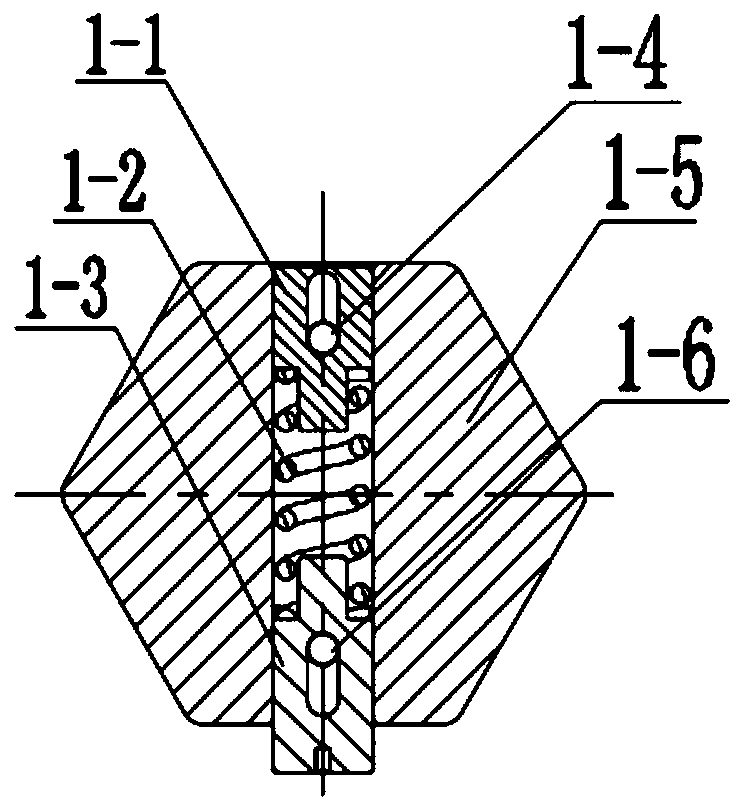

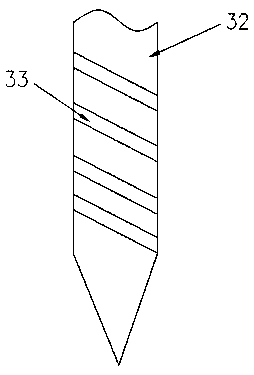

Spiral drill rod of coal mining machine

ActiveCN109854187ALarge contact surfaceHigh torque transmissionDrilling rodsDrilling casingsCoal miningBearing capacity

The invention discloses a spiral drill rod of a coal mining machine. The spiral drill rod comprises a drill rod cylinder assembly and a drill rod blade fixed to the periphery of the drill rod cylinderassembly, the drill rod cylinder assembly comprises a drill rod cylinder, unlocking devices are arranged at the end, opposite to a mounting guiding connection shaft, of the drill rod cylinder and located on the inner side of a drill rod stabilizer assembly at the end, opposite to the mounting guiding connection shaft, of the drill rod cylinder, and the pair of unlocking devices are symmetricallydistributed in the radial direction of the drill rod cylinder; and each unlocking device comprises an unlocking column, an upper ring, an unlocking spring and a lower ring, the upper ends of the unlocking columns make contact with the upper rings, the upper rings are embedded in the drill rod cylinder, the unlocking columns penetrate through the unlocking springs, the upper ends of the unlocking springs are connected with the unlocking columns, the lower ends of the unlocking springs are connected with the lower rings, the lower ends of the unlocking columns penetrate through the lower rings,and the lower rings are embedded in the drill rod cylinder. The spiral drill rod is high in bearing capacity, easy to manufacture and convenient to demount and mount.

Owner:CHINA UNIV OF MINING & TECH

Construction ground punching device and method

InactiveCN111088946AQuick punchNovel structural designDrill bitsConstructionsPunchingArchitectural engineering

The invention discloses a construction ground punching device and method. The device comprises a fixed base, a rotating platform and a punching mechanism. Supporting legs are mounted on the bottom ofthe fixed base, lifting type rollers are mounted on the supporting legs, the rotating platform is fixedly mounted on the fixed base, a supporting stand column is arranged in the middle of the upper end face of the rotating platform, a cross beam is vertically mounted on the top of the supporting stand column, a transverse sliding rail is mounted on the lower end face of the cross beam, a fixed plate assembly is mounted below the transverse sliding rail, a first oil cylinder mounting base and a second oil cylinder mounting base are in sliding connection to the transverse sliding rail, a first oil cylinder and a second oil cylinder are mounted between the first oil cylinder mounting base and the fixed plate assembly and between the second oil cylinder mounting base and the fixed plate assembly correspondingly, and the punching mechanism is mounted below the fixed plate assembly. The construction ground punching device is novel in structural design, rapid punching of a construction groundcan be achieved, meanwhile, the punching interval can be adjusted, different positions are punched, punching stability is good, and the work efficiency can be effectively improved.

Owner:南通謇辉贸易有限公司

Building drilling device convenient to use

InactiveCN108543972AIncrease temperatureAvoid jitterDrilling/boring measurement devicesPositioning apparatusHydraulic cylinderEngineering

The invention discloses a building drilling device convenient to use. The building drilling device comprises a main body. A hanging frame is arranged at the bottom of the main body. A hydraulic cylinder is arranged at the bottom of the hanging frame. A mounting plate is arranged at the bottom of the hydraulic cylinder. An electric drill is arranged on the mounting plate through a locking ring. A drill bit is arranged on the electric drill. A containing frame is arranged below the drill bit. A transverse limiting piece and a longitudinal limiting piece are arranged on the containing frame. Thetransverse limiting piece is slidably arranged on the containing frame through a first chute. A first connecting piece is arranged at the bottom of the transverse limiting piece. Pulleys are arrangedon both sides of the first connecting piece. A second scale and a second scale are arranged on the containing frame. A first pointer is arranged on the transverse limiting piece. The first pointer isclose to the first scale. The building drilling device convenient to use is simple in structure, convenient to use, low in labor intensity and high in drilling stability.

Owner:王立俊

Convenient glass drilling equipment

InactiveCN113246317AReduce shakingImproved drilling stabilityWorking accessoriesStone-like material working toolsDrive shaftStructural engineering

The invention relates to convenient glass drilling equipment. The equipment comprises a shell, a handle, a drill rod, a connector and a transmission shaft, the handle is arranged on the outer wall of the shell, a mounting hole is formed in the shell, the transmission shaft penetrates through the mounting hole, the drill rod and the transmission shaft are coaxially arranged, a driving device is arranged in the shell, the driving device is in transmission connection with one end of the transmission shaft, one end of the drill rod is mounted at the other end of the transmission shaft through the connector, at least two collecting mechanisms are arranged on the shell, the collecting mechanisms are evenly distributed in the circumferential direction with the axis of the transmission shaft used as the center, a cleaning mechanism is arranged on the drill rod, and each collecting mechanism comprises a through hole, a moving pipe, a sealing block, a moving disc, a first spring, a connecting assembly, a reset assembly and a collecting assembly. According to the convenient glass drilling equipment, the function of collecting chippings generated in the drilling period is achieved through the collecting mechanisms, and in addition, the function of automatically cleaning the drill rod is achieved through the cleaning mechanism, so that the convenience is improved.

Owner:广州星龙商业管理有限公司

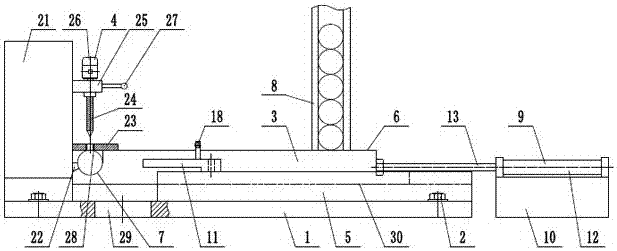

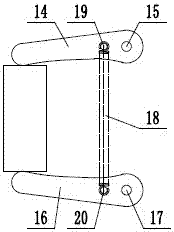

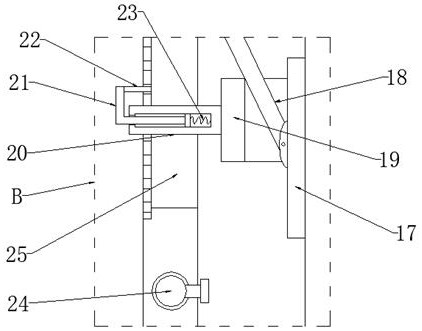

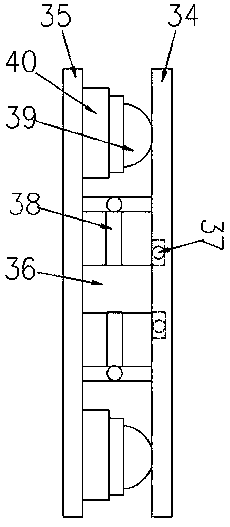

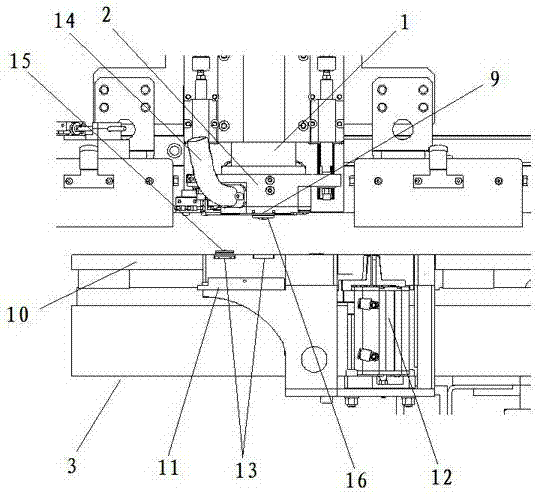

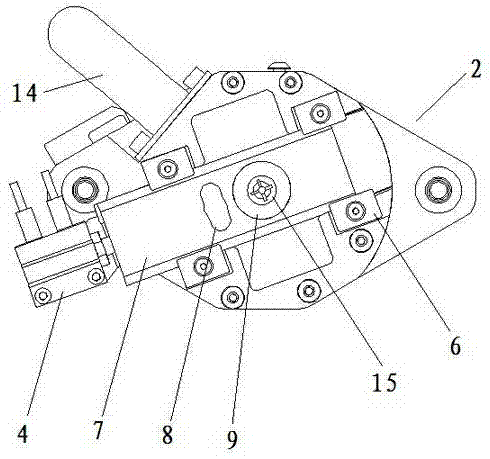

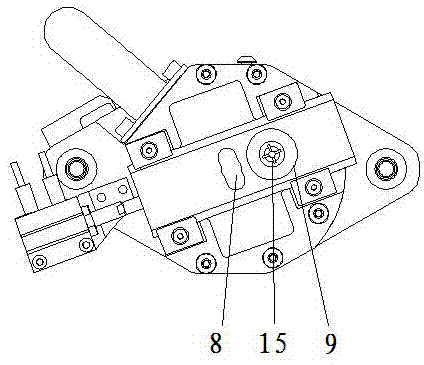

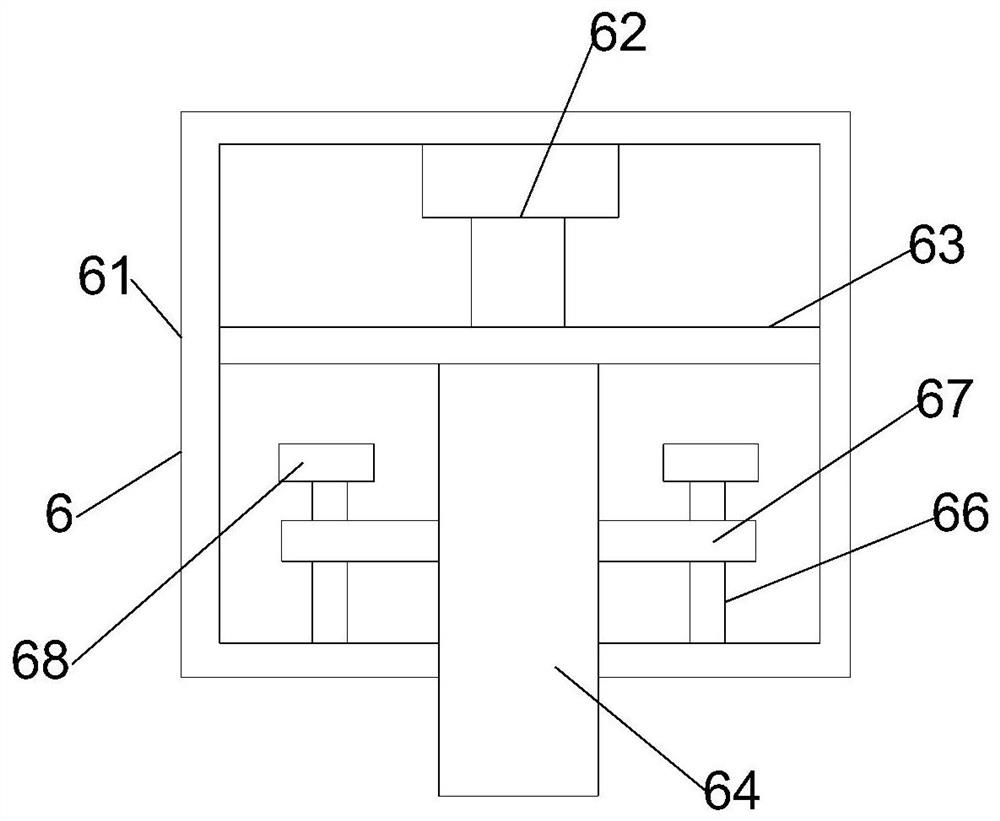

Switching method ofpress pin switching device of printed circuit board (PCB) boring machine

ActiveCN103042567BGuarantee processing qualityEasy to switchMetal working apparatusSlide plateEngineering

The invention discloses a press pin switching device of a printed circuit board (PCB) boring machine and a switching method thereof. The press pin switching device comprises a spindle unit, a scrap absorption cover unit and a worktable unit. One end of the scrap absorption cover unit is connected with the spindle unit, and the worktable unit is arranged below the scrap absorption cover unit. The scrap absorption cover unit comprises a rectilinear motion device, a sliding device and a scrap absorption cover main body. The rectilinear motion device and the sliding device are arranged on the scrap absorption cover main body. The sliding device comprises a sliding base and a sliding plate arranged on the sliding base, and one end of the sliding plate is connected with the rectilinear motion device. A tool changing position used for meeting the tool changing requirement and a press pin position used for press pins in different sizes to be placed at are arranged on the sliding plate.

Owner:SUZHOU VEGA TECH CO LTD

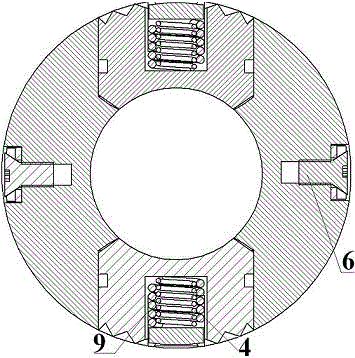

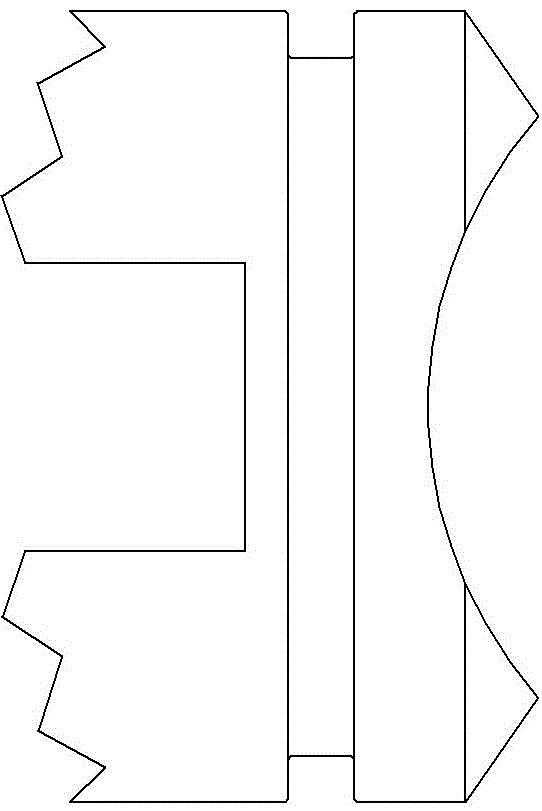

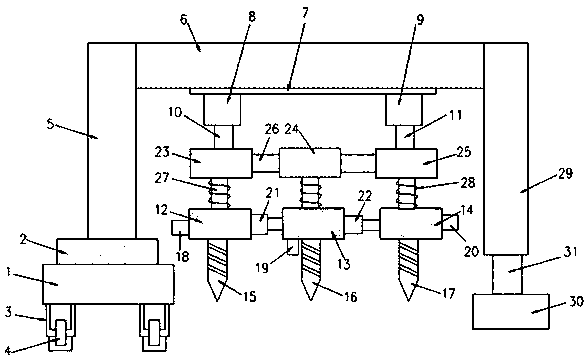

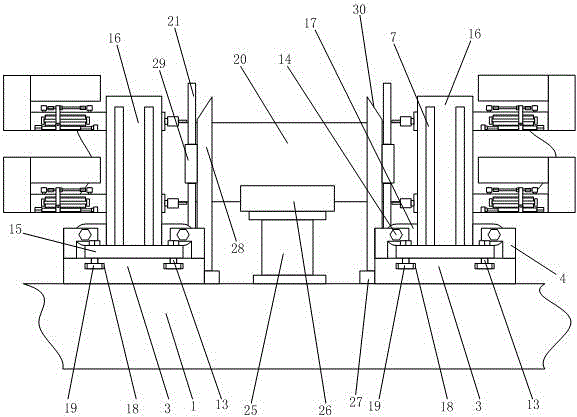

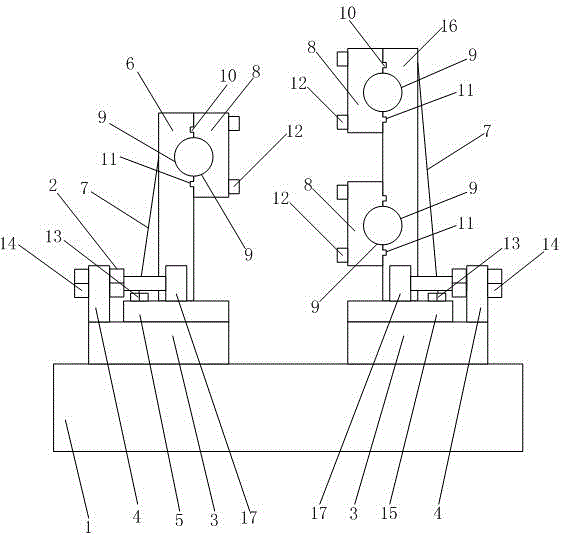

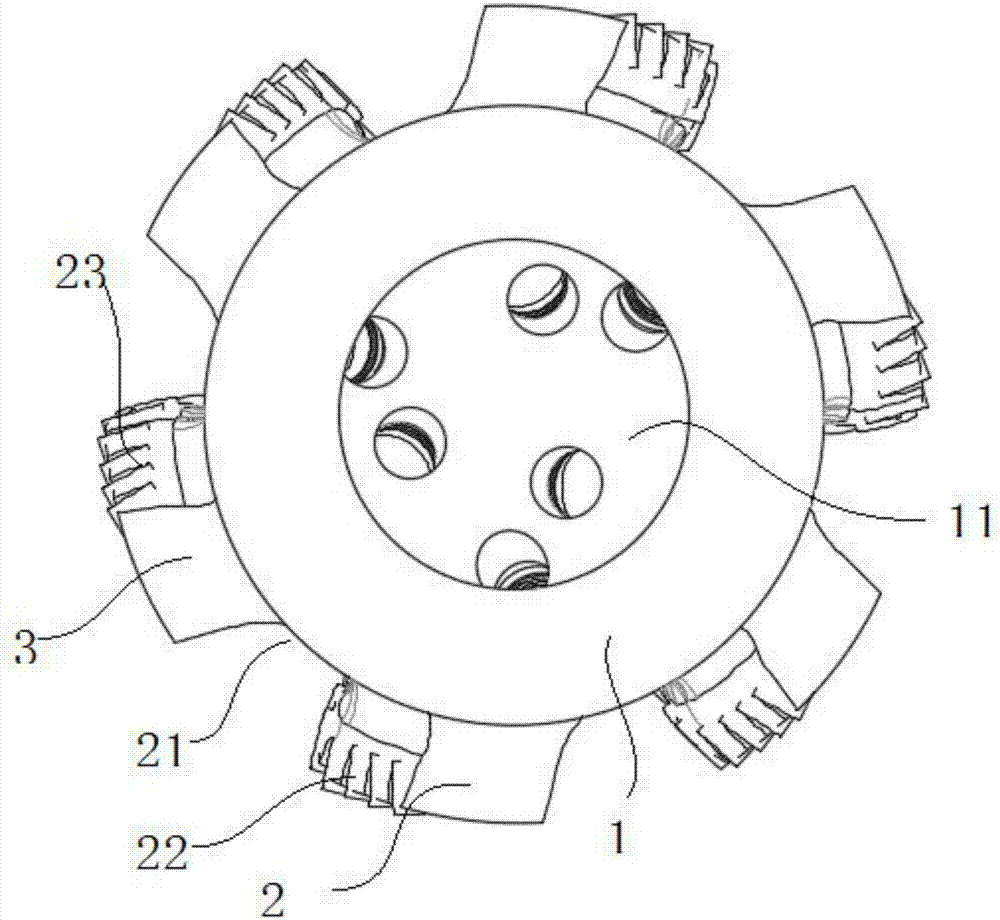

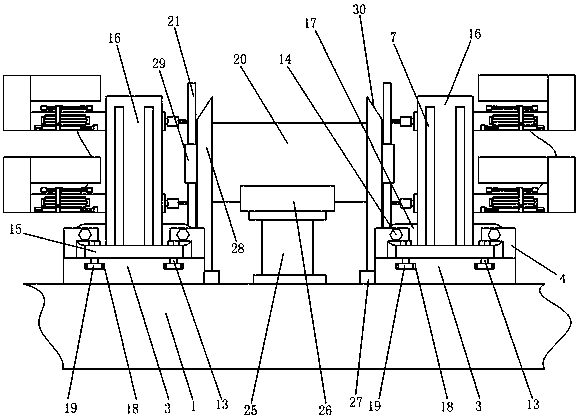

Three-hole one-time equilibrium drilling device for solar mirror bracket

ActiveCN106825675AAvoid damageServe as a balance limitSpectales/gogglesBoring/drilling machinesSolar mirrorForce balance

The invention provides a three-hole one-time equilibrium drilling device for a solar mirror bracket. The three-hole one-time equilibrium drilling device comprises a rectangular base, two double-hole drilling units, two single-hole drilling units, one mirror bracket bearing unit and two axial limiting units. The three-hole one-time equilibrium drilling device provided by the invention is symmetrically arranged on the rectangular base by adopting the two double-hole drilling units and two single-hole drilling units, so that two sides are respectively subjected to symmetrical drilling, the two sides are in force balance, not only is the drilling efficiency high, but also higher drilling stability is obtained, and the drilling accuracy is ensured.

Owner:江苏锐达科技有限公司

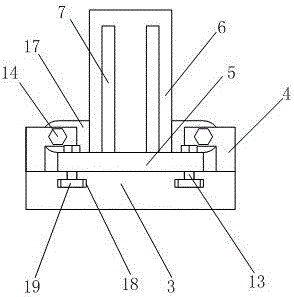

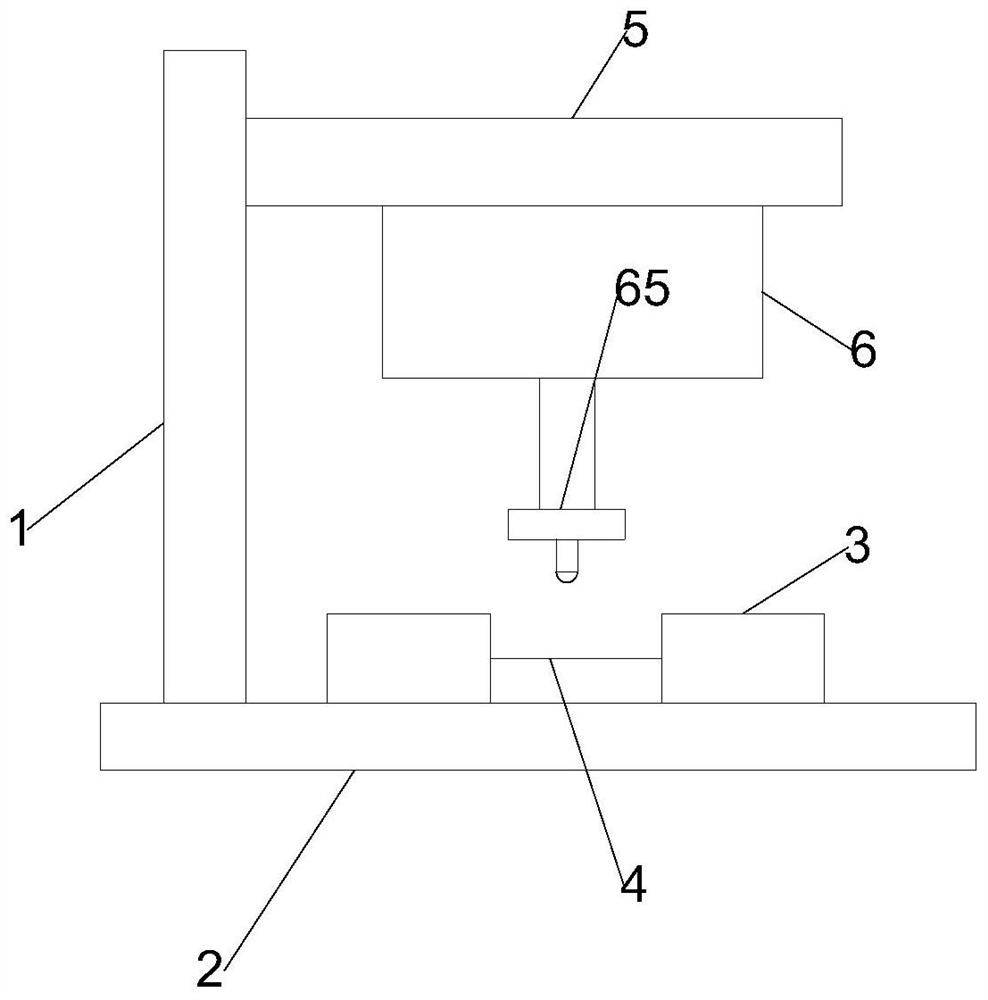

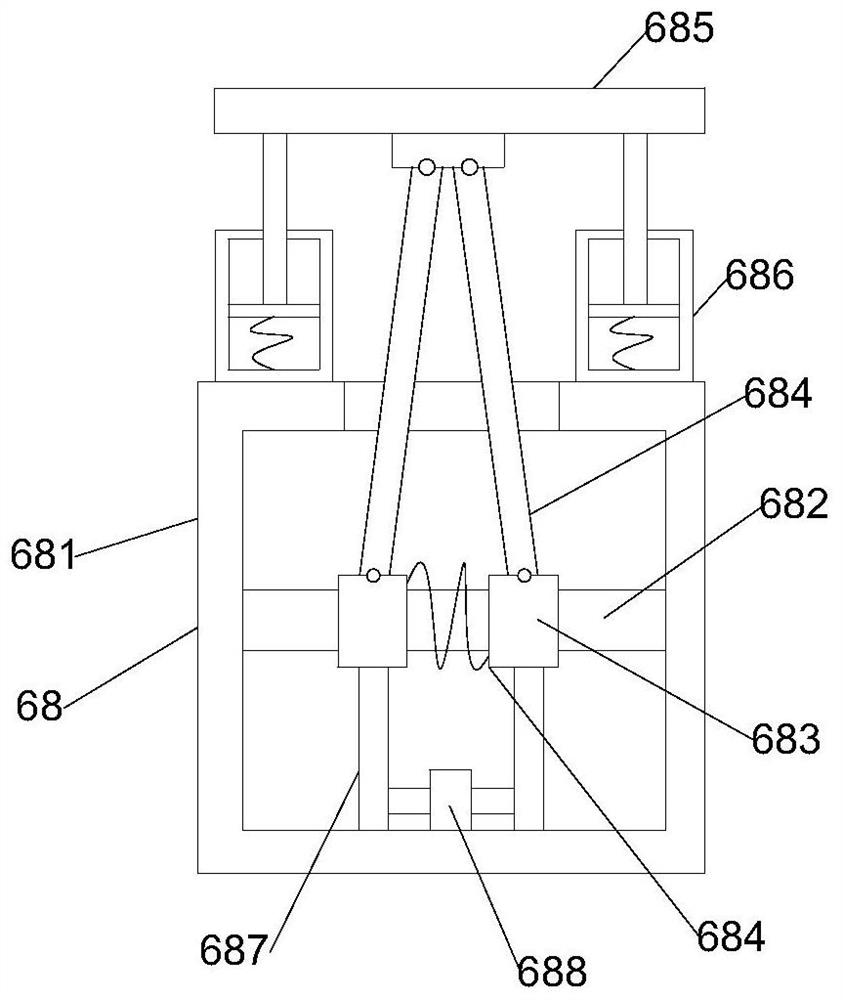

Complex industrial detection device based on data-driven modeling and model-free adaptive control

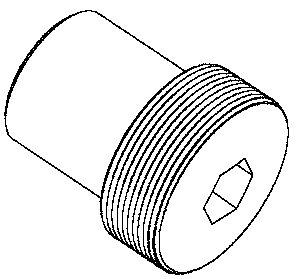

InactiveCN112650178AImproved drilling stabilityPlay a buffering effectTotal factory controlProgramme total factory controlControl engineeringScrew thread

The invention provides a complex industrial detection device based on data-driven modeling and model-free adaptive control. The complex industrial detection device comprises a machining column and a base, wherein fasteners are symmetrically arranged on the base and used for fixing a device body, a mounting seat is arranged on the upper portion of the machining column, and a power device is arranged at the bottom of the mounting seat. According to the invention, the two ends of the device body are inserted into the fasteners, the handle is rotated, the power shaft rotates, the threaded sleeve rotates, then the threaded movable rod drives the trapezoidal base to move, the two coordination blocks and the trapezoidal base are arranged in a matched mode, the hinged inclined rod rotates downwards so as to jointly clamp the device body through the two clamping heads, the winding rope contracts to drive the mounting transverse column to move, then the angle of the mounting inclined rod is changed so as to drive the mounting sleeve block to slide on the mounting vertical column, and the movable contact sheet and the static contact sheet make contact with the alarm to give an alarm, so thatthe device body is reminded of fixing completion.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

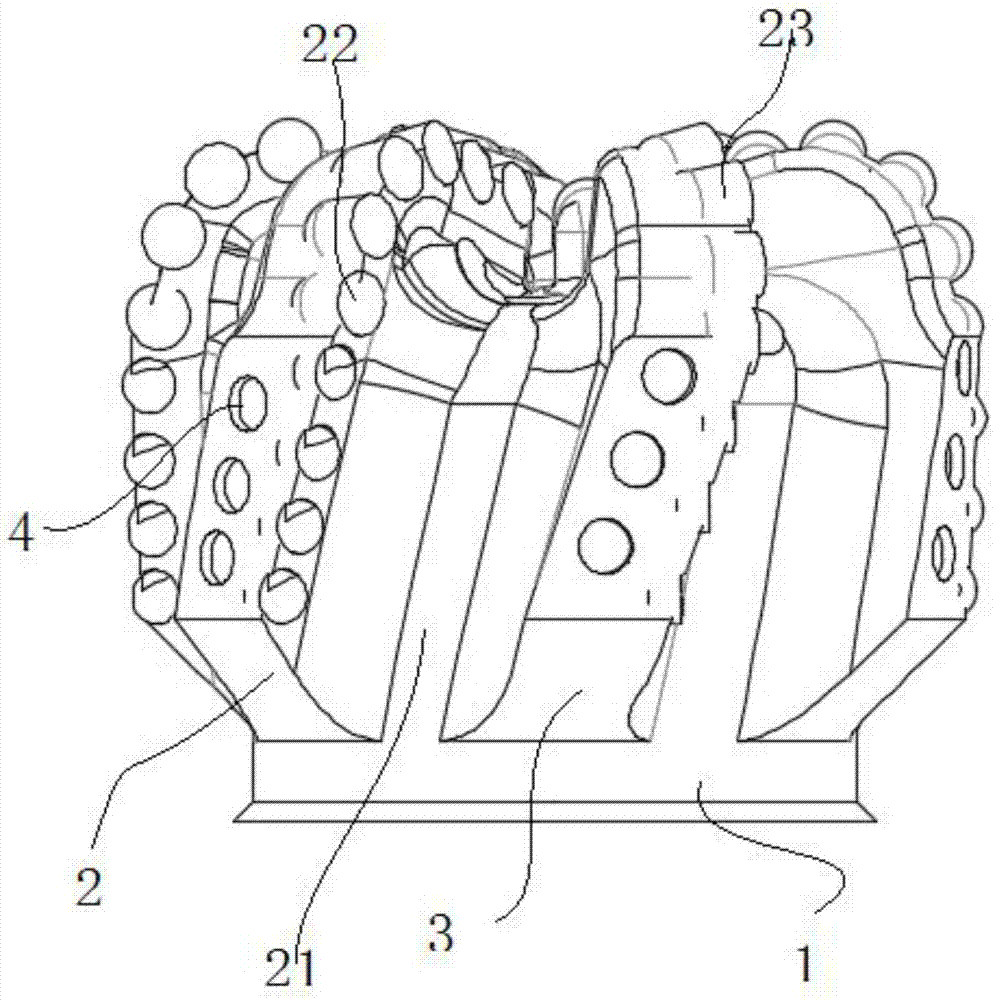

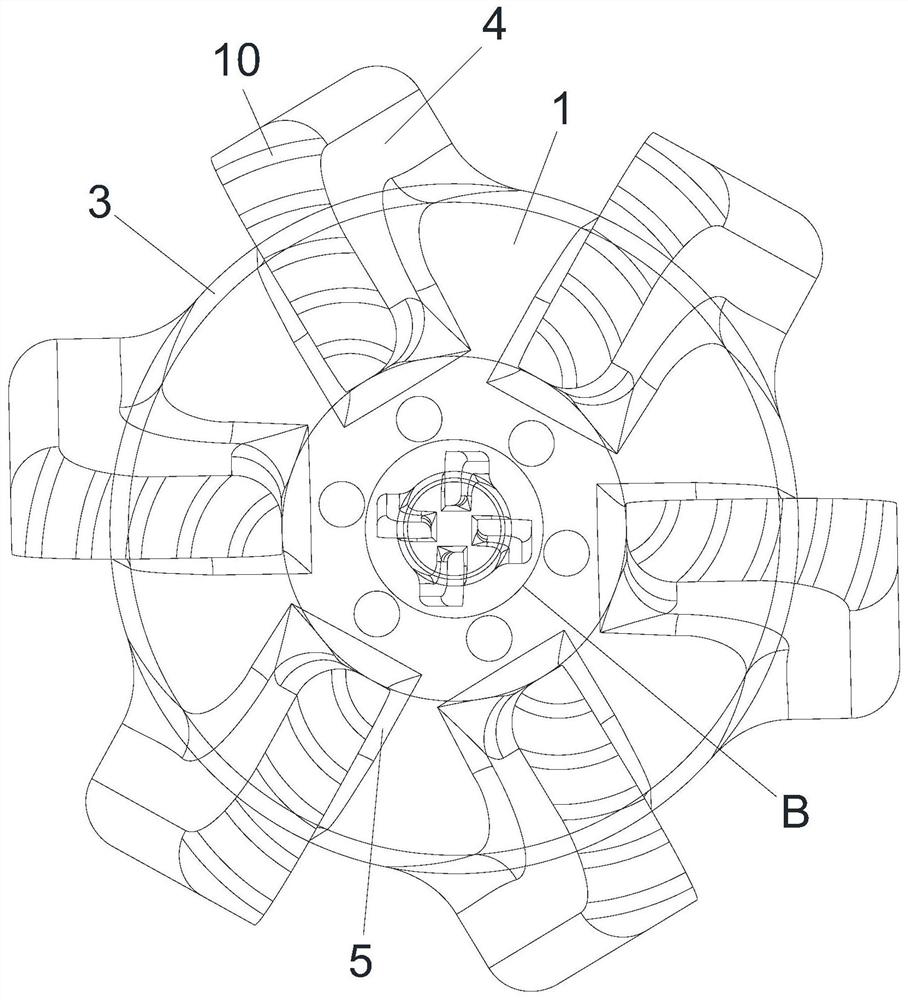

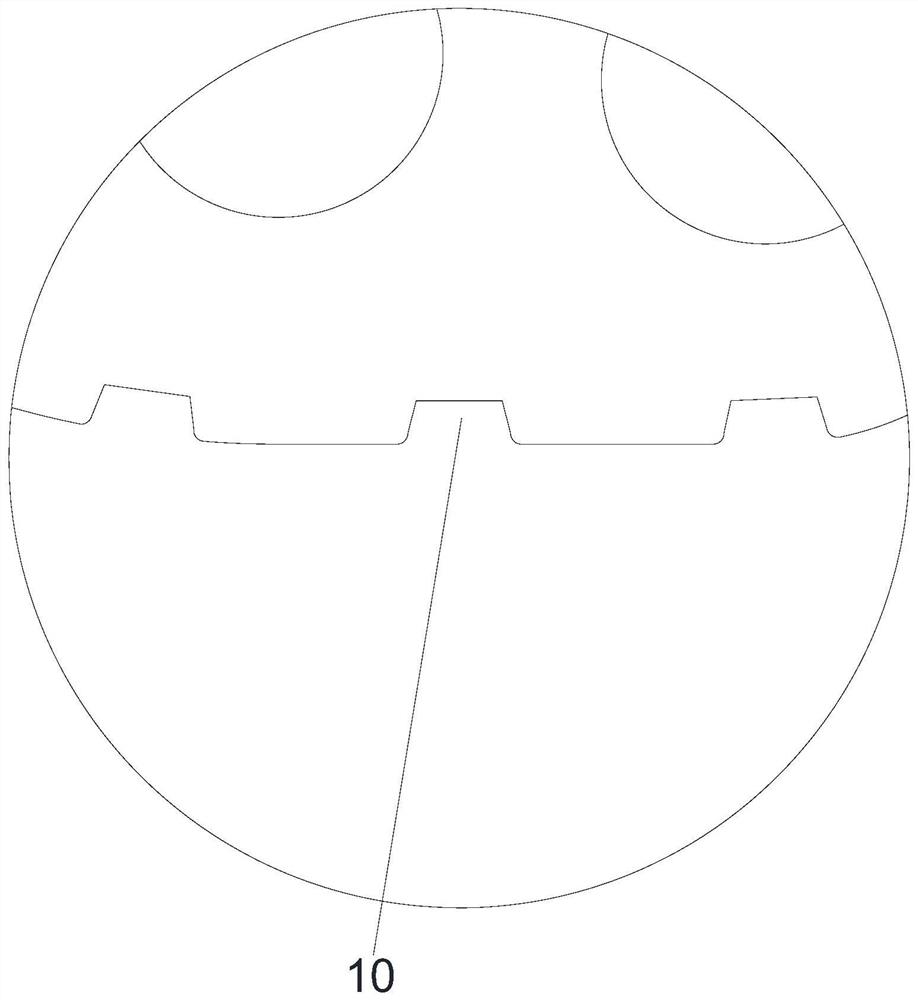

PDC drill bit for well drilling

ActiveCN106907112APrevent guide deflectionUnbalance reliefDrill bitsConstructionsMining engineeringWell drilling

The invention discloses a PDC drill bit for well drilling. The PDC drill bit comprises a drill bit body, a plurality of cutting edges and a plurality of flushing openings. A flushing cavity is formed in the drill bit body; the top ends of the cutting edges are reduced in sequence to form a spiral line structure, the cutting edges are arranged at a crown part of the drill bit body in a protruding mode, the angles formed between the adjacent cutting edges are different, a discharging groove is formed between any two adjacent cutting edges, a plurality of cutting tooth and a plurality of auxiliary cutting edges are arranged on the same sides of the cutting edges, the auxiliary cutting edges are arranged in the centers of the discharging grooves in a protruding mode and have the number equal to that of the discharging grooves, the tops of the auxiliary cutting edges are located at the midpoints of the connecting line of the top of the highest cutting edge and the top of the lowest cutting edge, and a plurality of auxiliary cutting teeth are arranged on the auxiliary cutting edges in the direction of the same sides of the cutting edges. The flushing openings are communicated with the flushing cavity. The problem that when a drill bit generates unbalanced force at the bottom of a well, the drill bit deflects is solved, and hole drilling stability is greatly improved.

Owner:YICHANG SHENDA PETROMACHINE

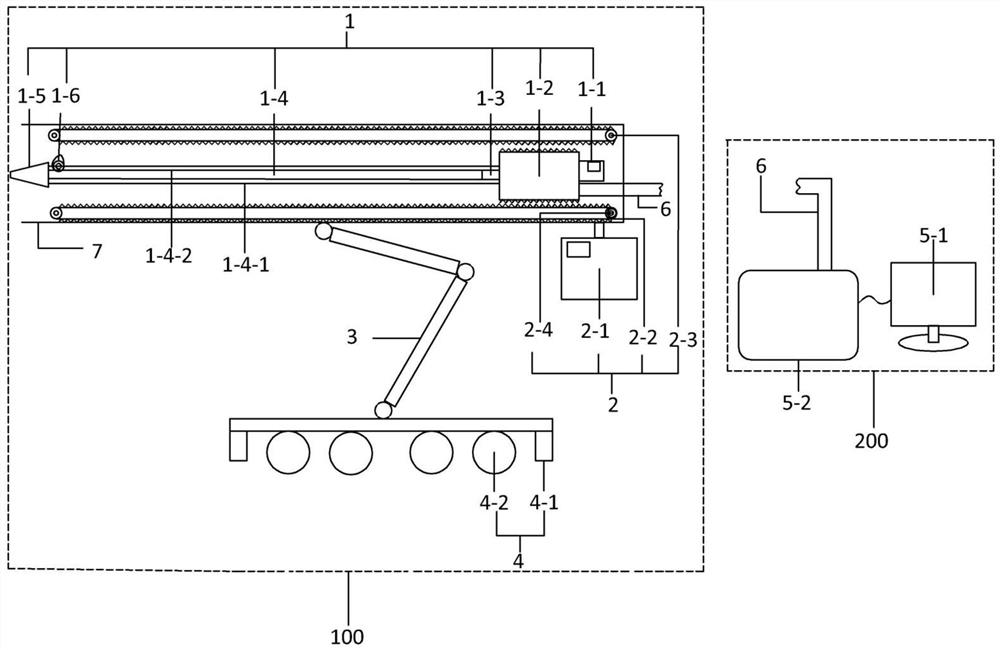

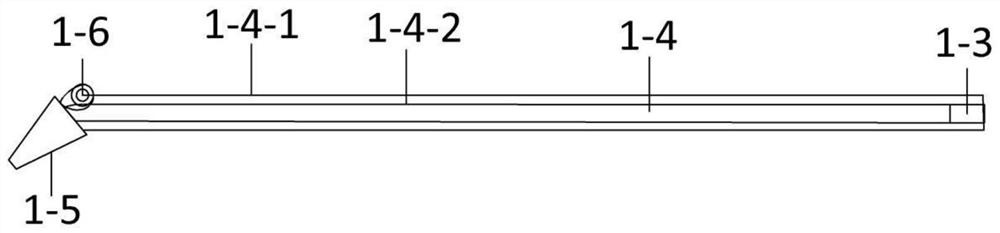

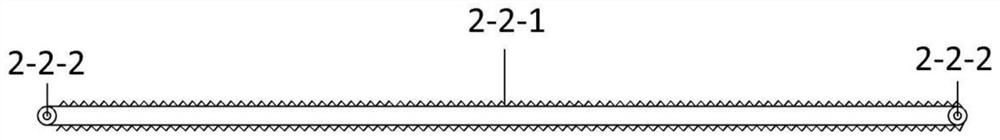

A high-pressure water jet drilling equipment and construction method for bolt construction in mines

ActiveCN112901078BImprove construction efficiencyHigh borehole alignmentLiquid/gas jet drillingAnchoring boltsMicrocomputerWater flow

The present invention proposes a high-pressure water jet drilling equipment and construction method for bolt construction in mines. The equipment includes a working part and a control part, and the working part includes a casing and an injector arranged inside the casing and a propeller, the injector is used to inject high-pressure water flow to the target area to realize drilling, the propeller is connected with the injector in transmission, and is used to drive the injector to move back and forth, and the control part includes a water pump microcomputer and a high-pressure water pump , the water pump microcomputer is connected with the high-pressure water pump, and the high-pressure water pump is connected with the injector through the water inlet pipe. The invention synchronizes the drilling and hole cleaning, which improves the efficiency of anchor rod construction. Compared with the traditional metal drill bit drilling, the high-pressure water jet has the advantages of high drilling alignment, low drilling temperature, and drilling stability. Advantages of high quality and high security.

Owner:NANJING TECH UNIV +2

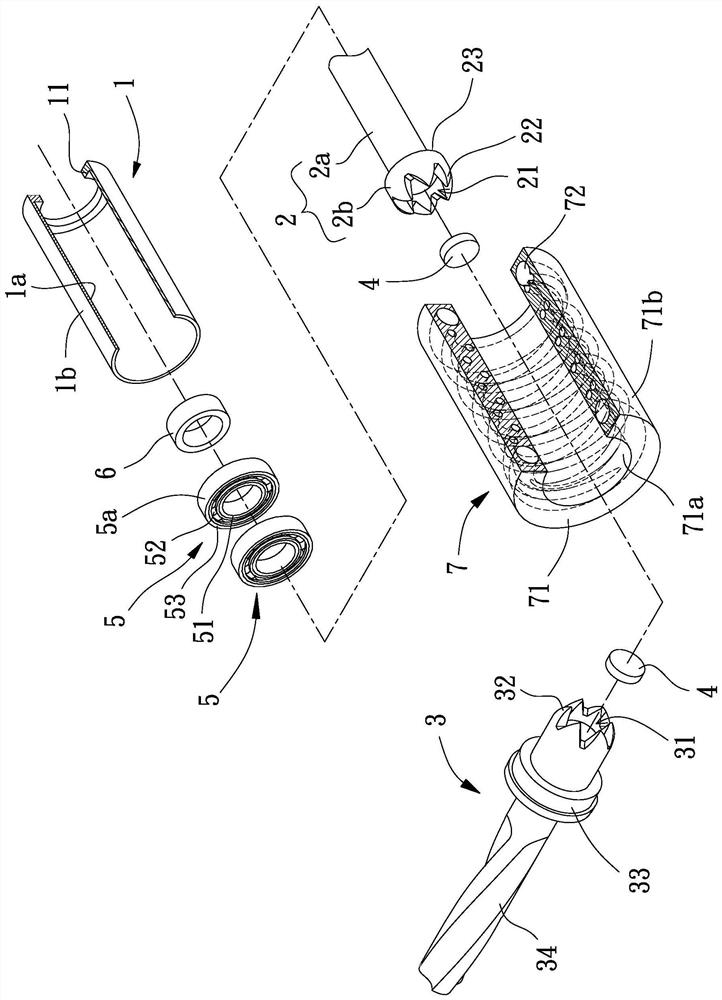

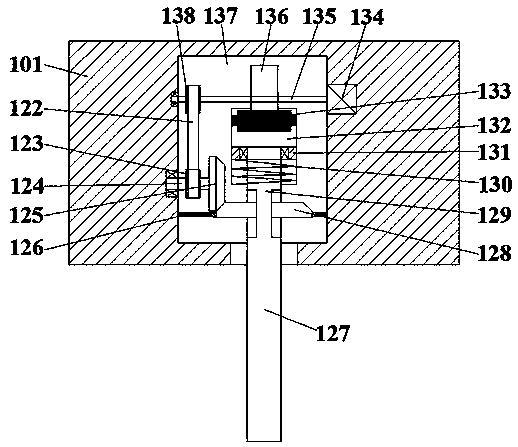

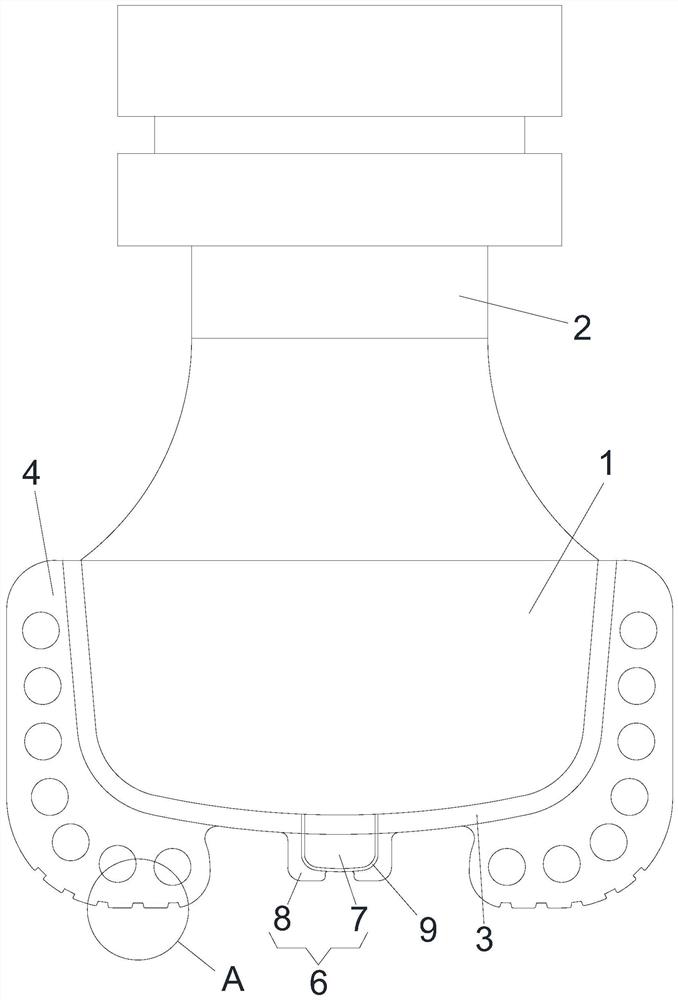

Orthopedic implant instrument

PendingCN114469244AAvoid damageReduce frictionSurgeryPermanent magnetsOrthopedic departmentMechanical engineering

The invention provides an instrument for an orthopedic implant. The instrument is used for solving the problem that an existing orthopedic drilling tool is prone to causing soft tissue injury. Comprising a sleeve; the transmission rod is provided with a transmission piece located at one end of a rod body, the transmission piece is located in the sleeve and provided with a first containing groove, and a plurality of first meshing teeth are arranged around the first containing groove; the drilling rod is provided with a plurality of second meshing teeth which are arranged around a second containing groove, a combination part is located between the second containing groove and a blade part, the combination part is combined with the sleeve, and the blade part is located outside the sleeve; and the two magnets are respectively arranged in the first accommodating groove and the second accommodating groove, and the same poles of the two magnets are opposite to each other.

Owner:METAL INDS RES & DEV CENT

A three-hole one-time balanced drilling device for solar mirror frames

ActiveCN106825675BImprove structural strengthImprove structural stabilitySpectales/gogglesBoring/drilling machinesSolar mirrorForce balance

The invention provides a three-hole one-time equilibrium drilling device for a solar mirror bracket. The three-hole one-time equilibrium drilling device comprises a rectangular base, two double-hole drilling units, two single-hole drilling units, one mirror bracket bearing unit and two axial limiting units. The three-hole one-time equilibrium drilling device provided by the invention is symmetrically arranged on the rectangular base by adopting the two double-hole drilling units and two single-hole drilling units, so that two sides are respectively subjected to symmetrical drilling, the two sides are in force balance, not only is the drilling efficiency high, but also higher drilling stability is obtained, and the drilling accuracy is ensured.

Owner:江苏锐达科技有限公司

Oil content exploration equipment

InactiveCN110259372AReduce pollutionSimple structureReciprocating drilling machinesConstructionsEnvironmentally friendlyOil content

The invention discloses oil content exploration equipment. The oil content exploration equipment comprises an operating machine body, wherein an extending and pressing machine body is fixedly mounted at the top of the operating machine body, and the operating machine body is internally provided with a receding groove with a downward opening; and the oil content exploration equipment further comprises a drilling power machine body and a hydraulic driving mechanism, the drilling power machine body is slidably mounted in the receding groove, and the hydraulic driving mechanism can maintain the outward pressure at any time. The oil content exploration equipment has simple structure and convenient operation, the hydraulic driving mechanism is used for being mutually matched with the drilling power machine body, the extending and pressing machine body and an impact mechanism are further arranged in the drilling power machine body, so that stable impact drilling is achieved, the design is ingenious, matching is close, the function is comprehensive, and the drilling efficiency is high; a hydraulically driven stabilization mechanism is arranged at the top of the operating machine body to achieve stable drilling positioning, the drilling stability is improved, straightness of drilling is high; and an ash-receiving cover mechanism which can be freely stored is arranged on the outer side of the operating machine body, so that dust pollution is reduced, environmentally friendly operation is apposite, safety hazards are further reduced, and the practicability is high.

Owner:嘉兴纳创生物科技有限公司

Drilling apparatus for music box production

InactiveCN111958006AGuaranteed pronunciation effectImproved drilling stabilityFeeding apparatusPositioning apparatusElectric machineryEngineering

The invention discloses a drilling apparatus for music box production. The drilling apparatus for music box production comprises a fixed base, a sliding chute and a bearing are arranged on the fixed base, a lower end of a sliding base is in sliding and clamping connection with the sliding chute, a ring-shaped guide groove is arranged on the sliding base, the lower end of a first chuck is providedwith a guide ball, the guide ball is in sliding and clamping connection with the ring-shaped guide groove, a threaded rod is in cup joint on the bearing, a bracket is arranged on the sliding base, anair cylinder is arranged on the bracket, a telescopic rod of the air cylinder is provided with a first motor thereon, a motor shaft of the first motor and a second chuck are arranged fixedly, and upper and lower ends of a support column are in clamping connection with the first chuck and the second chuck. Drilling stability is improved, drilling quality uniformity is improved greatly, thereby, drilling quality of a column surface of the support column and a later sound production effect of a music gift box can be guaranteed, stability and drilling stability of a time when the sliding base is pushed manually are improved, and an operator is enabled to conveniently observe quality of a through hole drilled on the surface of the support column and a drilling state through an operation openingin real time.

Owner:QUANNAN LIXIN TECH CO LTD

Multi-stage hydraulic pressurizer based on mechanical device

ActiveCN107091060BSimple structureExtended service lifeDrilling rodsDrilling casingsUpper jointThree stage

Owner:山东王晁煤电集团新能发电有限公司

PDC drill bit with stable tool face for directional drilling

ActiveCN113294096APrecise drilling directionLess prone to deviationDrill bitsConstructionsStructural engineeringEngineering physics

The invention relates to the technical field of PDC drill bits, in particular to a PDC drill bit with a stable tool face for directional drilling. The drill bit can effectively prevent a drilling direction from deviating, is provided with the stable tool face, and comprises a drill bit base body, a drill handle is arranged at the top end of the drill bit base body, first hard layers are arranged on the surfaces of the bottom end and the side face of the drill bit base body, several first blades are evenly arranged at the bottom end and the side face of the drill bit base body, a positioning drill is arranged in the middle of the bottom end of the drill bit base body and comprises a positioning drill base body and several second blades, each second blade is arranged between the bottom end and the side face of the positioning drill base body, a second hard layer is arranged on the surface of each positioning drill base body, several chip grooves are formed in the bottom end of each first blade, each chip groove is in an arc shape, and the radius of each chip groove away from the middle of the drill bit base body is larger than that of the chip groove close to the middle of the drill bit base body.

Owner:河北锐石钻头制造有限公司

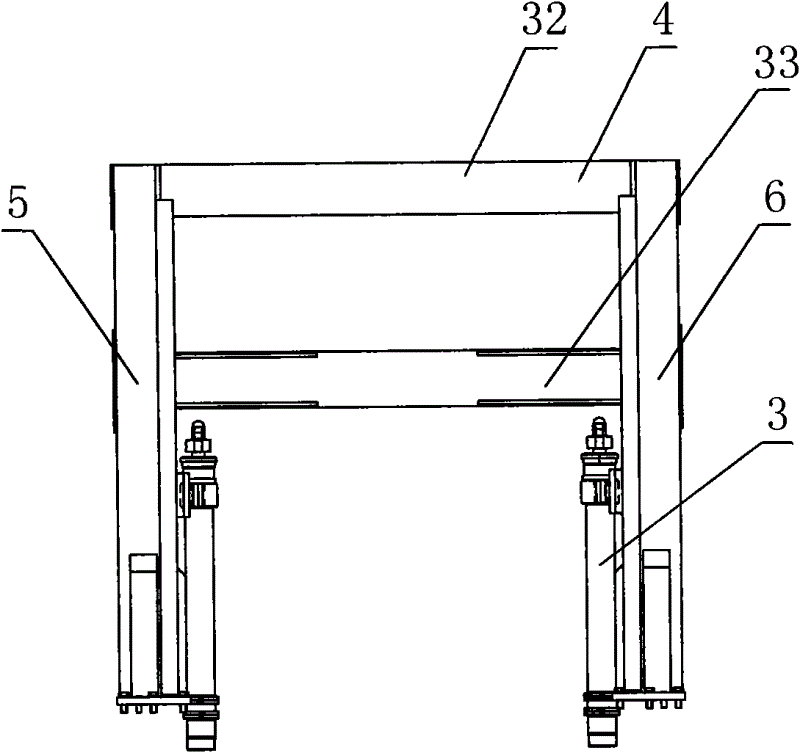

Engineering driller

InactiveCN101812966BRealize moving up and downIncrease the itineraryDrilling drivesBulkheads/pilesArchitectural engineeringRisk stroke

The invention discloses an engineering driller comprising a power head, a driving drill rod, two feeding oil cylinders, a portal frame and a chuck for vertically fixing the driving drill rod opposite to a stand, wherein the driving drill rod vertically passes through a main shaft of the power head, the portal frame comprises a left vertical post and a right vertical post, and both sides of the power head are respectively clamped on the left vertical post and the right vertical post and are in single-freedom sliding fit with vertical posts at the corresponding side; and the two feeding oil cylinders are respectively fixed and arranged at the bottoms of the left vertical post and the right vertical post, piston rods of the feeding oil cylinders are vertically and upwards fixed with the power head below which the chuck is arranged, and the driving drill rod is clamped in the chuck. A power head support frame of the engineering driller adopts a portal vertical post structure, both sides of the power head are respectively clamped on the left vertical post and the right vertical post of the portal frame, the power head moves up and down through the feeding oil cylinders, the stroke can be about 1 meter, and therefore, the engineering driller has high precision of vertical movement; because the chuck is arranged below the power head, an operator can directly operate the engineering driller without climbing the driller; and the engineering driller has the advantages of safety, convenience and high efficiency.

Owner:CHONGQING EXPLORATION MACHINER FACTORY

A kind of anti-destructive ground drilling gas drainage method

ActiveCN112012783BImprove the extraction effectImprove securityDrilling rodsFluid removalMining engineeringWell drilling

An anti-destructive ground drilling gas drainage method belongs to the technical field of coal mine gas drainage methods, which can solve the problems that the ground vertical drilling is easily damaged due to the movement of the working face, and the construction of L-shaped drilling is difficult and costly. Before coal seam mining, Spud drilling from 3‑5 m outside the edge of the surface mobile basin, drill vertically downward to stop at 30‑50 m above the fractured zone, and then go down into a vertical rigid pipe; inwardly stagger the direction of 40‑60° return airway Deviation; the drilling section from the beginning of deflection to the junction of the upper boundary line of the collapse zone and the mining stress boundary line on the side of the return airway is run into the flexible casing, and the upper boundary line of the collapse zone and the mining stress boundary on the side of the return airway The flexible screen pipe is lowered into the drilling section from the junction of the line to the floor of the mining coal seam, and the surface wellhead is connected with the pumping station. The invention solves to a certain extent the problem of damage to surface drainage drilling caused by advancement of the working face, and greatly improves drilling stability.

Owner:TAIYUAN UNIV OF TECH

Loose rock body drilling device and method

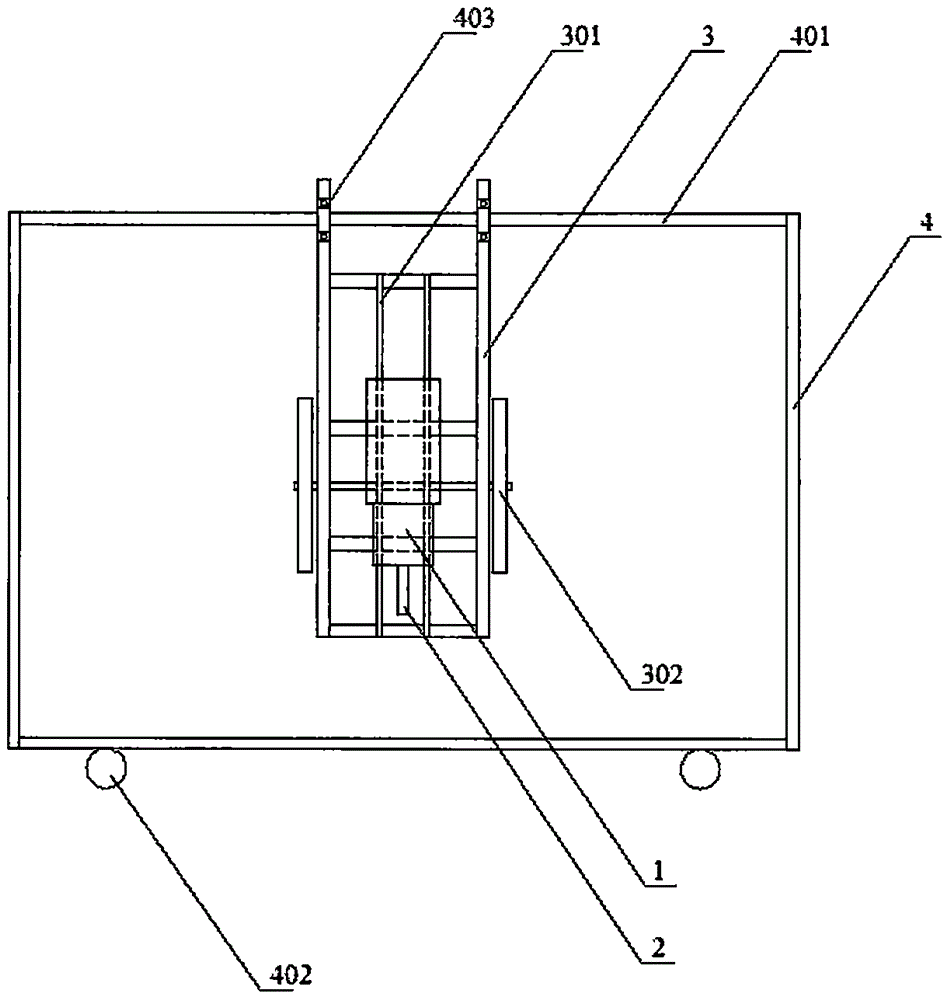

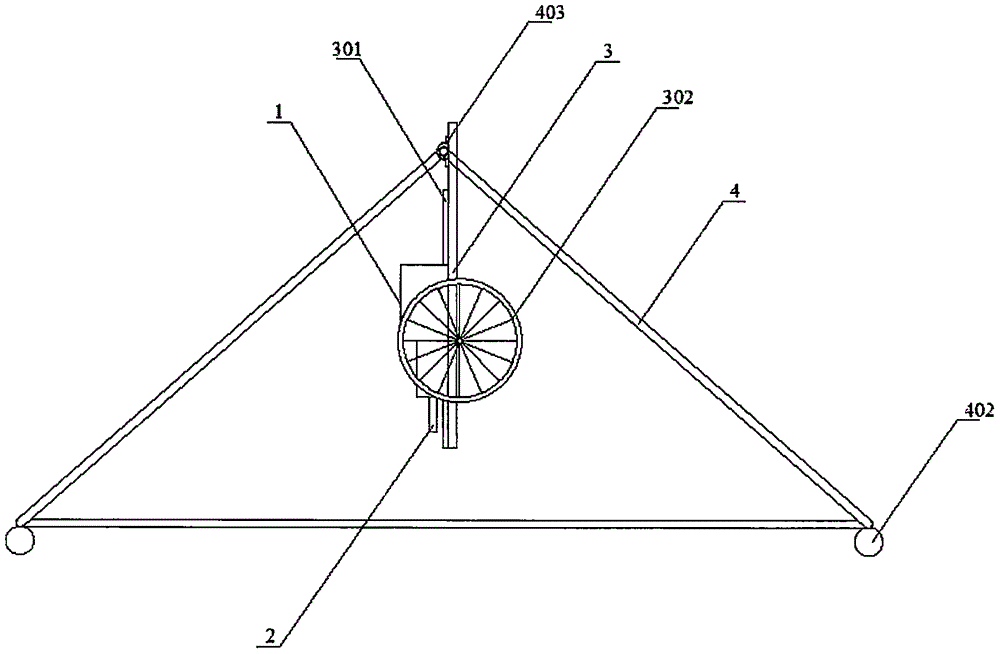

ActiveCN106089077ASolve the problem of easy drilling when drilling,Solve the problem of low porosityDerricks/mastsDrilling machines and methodsReciprocating motionDrilling machines

The invention provides a loose rock body drilling device. The loose rock body drilling device comprises a drilling machine, a drilling rod, a positioning vertical platform and a supporting truss; the drilling machine and the drilling rod are fixed on the positioning vertical platform and the drilling rod is vertical to the ground; the positioning vertical platform is fixed on the supporting truss; guide rails are mounted on the positioning vertical platform; under a working state of the drilling machine, the drilling machine does reciprocating motion on the guide rails; the supporting truss is of a herringbone shape and comprises a transverse beam; rolling wheels are mounted at the bottom of the supporting truss and the transverse beam is used for fixing the positioning vertical platform; and the rolling wheels are used for moving the supporting truss together with the drilling machine to a pre-set position when the drilling machine needs to work at other places. The loose rock body drilling device is simple in structure and easy to operate; and the problems that the drilling efficiency is low, the hole forming rate is low and the safety is poor when drilling and grouting work is carried out in a loose rock body can be effectively solved.

Owner:CCTEG CHINA COAL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com