Switching method ofpress pin switching device of printed circuit board (PCB) boring machine

A switching device and drilling machine technology, which is applied in metal processing and other directions, can solve problems such as unsatisfactory board surface compression state, unsatisfactory vacuum negative pressure, and influence on the quality of micro-hole processing, so as to achieve fast and reliable tool change , The switching operation is simple and convenient, and the effect of improving the drilling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

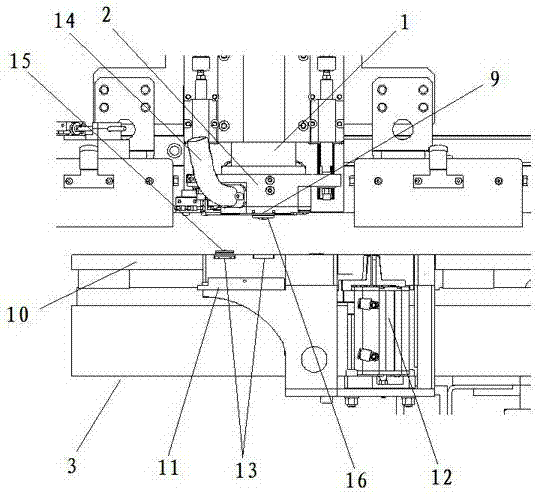

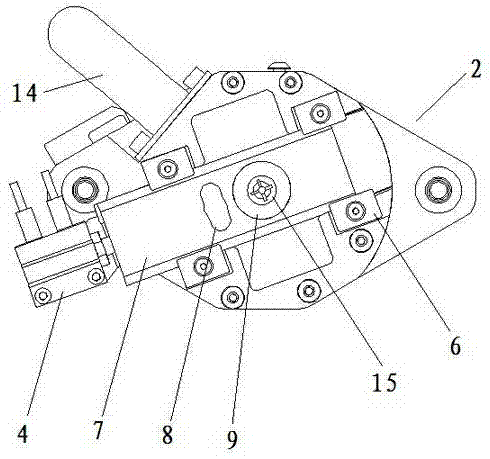

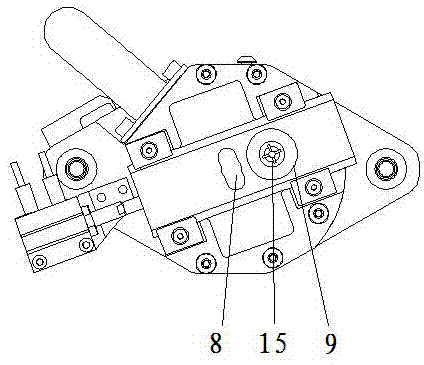

[0023] Such as figure 1 and 2 As shown, an embodiment of the present invention includes a main shaft unit 1, a dust suction hood unit 2 and a workbench unit 3, one end of the dust suction hood unit 2 is connected to the main shaft unit 1, and the workbench unit 3 is arranged on the dust suction hood unit 2 below. The dust hood unit 2 includes a linear motion device 4, a sliding device and a dust hood main body 5, the linear motion device 4 and the sliding device are arranged on the dust hood main body 5, the sliding device includes a slide seat 6 and a slide plate 7, and the slide plate 7 is arranged on On the slide seat 6, one end of the slide plate 7 is connected with the linear motion device 4; the slide plate is provided with a tool changing position 8 for meeting tool changing requirements and a presser foot position 9 for placing presser feet of different sizes. The chip suction hood unit 2 is also provided with a dust suction pipe 14 for removing dust and chips gener...

Embodiment 2

[0028] The rest are the same as in Embodiment 1, except that the fixing device 11 is provided with at least two presser foot transfer positions 13 for the transfer of the presser foot. The number of indexing positions in the placed presser foot can meet the processing of various holes with different diameters and sizes.

Embodiment 3

[0030] The rest is the same as that of Embodiment 1, the difference is that the linear motion device 4 is a hydraulic cylinder or a linear motor, and different work requirements can be met by setting different power sources.

[0031]The beneficial effects of adopting this technical solution are: meeting the needs of drilling and tool changing during small-diameter machining, fast and reliable tool changing, avoiding penetration of different presser feet, improving drilling stability, and effectively reducing the negative pressure caused by micro-hole drilling. The phenomenon of plate bulge around the micro-hole is affected, ensuring the processing quality of the micro-hole, the presser foot switching operation is simple and convenient, the reliability is good, and the practicability is strong.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com