Loose rock body drilling device and method

A drilling device and drilling location technology, applied in drilling equipment and methods, support devices, drilling equipment, etc., can solve problems such as difficulties in grouting drilling, reddening and softening of drill bits, and stuck drill, so as to avoid high temperature Steam injury accident, low cost, and the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

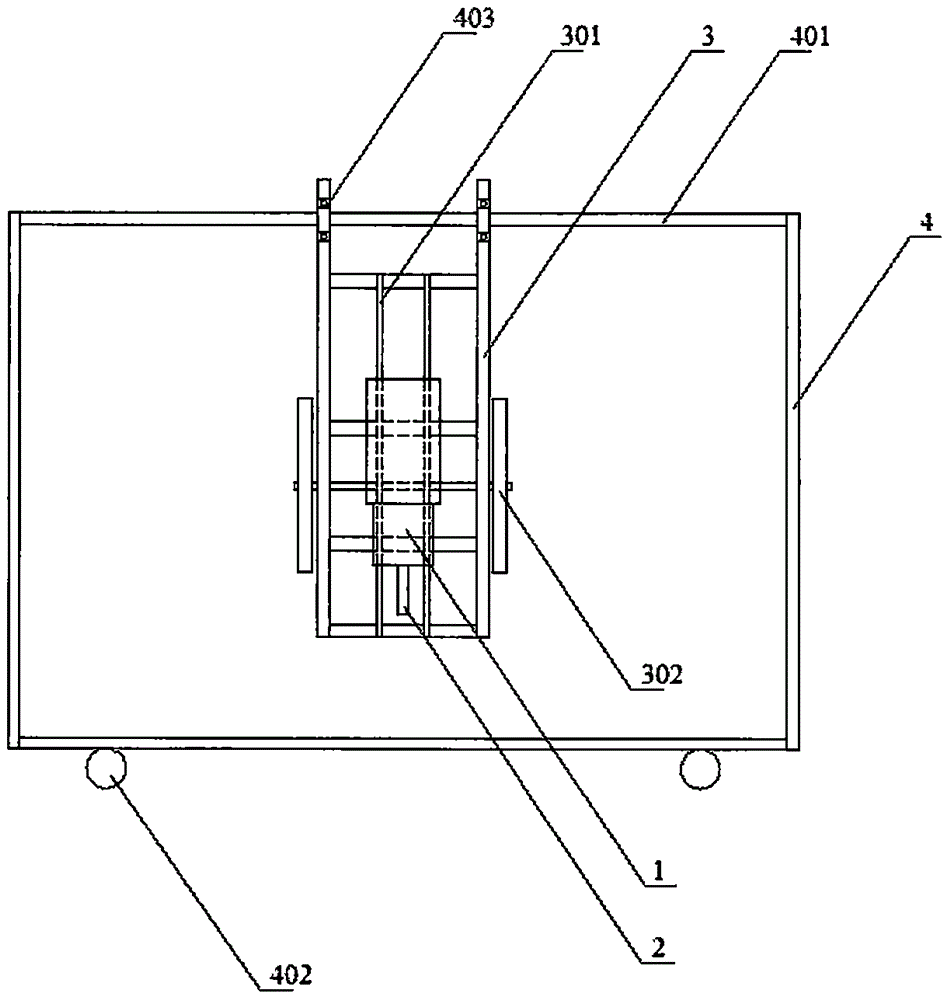

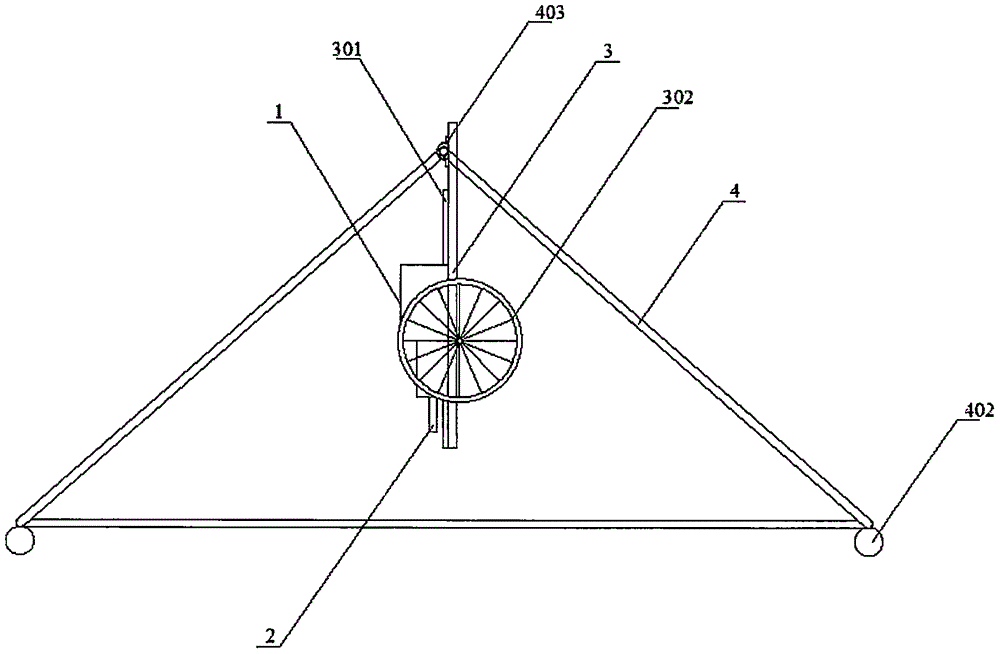

[0025] The loose rock drilling device includes a drilling rig 1, a drilling rod 2, a positioning vertical platform 3 and a support truss 4; the drilling machine 1 is fixed on the positioning vertical platform 3 together with the drilling rod 2, and the drilling rod 2 perpendicular to the ground; the positioning vertical platform 3 is fixed on the supporting truss 4; the positioning vertical platform 3 is equipped with a guide rail 301; the supporting truss 4 is a herringbone structure, including a beam 401, and rollers 402 are installed at the bottom , the beam 401 is used to fix the positioning stand 3, and the roller 402 is used to move the support truss 4, together with the drilling rig 1, to a predetermined position when the drilling rig 1 changes locations.

[0026] In this embodiment, the drilling machine 1 is a down-the-hole drilling machine.

[0027] In this embodiment, the roller 402 is a universal wheel.

[0028] The method for drilling in loose rock body using the ...

Embodiment 2

[0033] The loose rock drilling device includes a drilling rig 1, a drilling rod 2, a positioning vertical platform 3 and a support truss 4; the drilling machine 1 is fixed on the positioning vertical platform 3 together with the drilling rod 2, and the drilling rod 2 perpendicular to the ground; the positioning vertical platform 3 is fixed on the supporting truss 4; the positioning vertical platform 3 is equipped with a guide rail 301; the supporting truss 4 is a herringbone structure, including a beam 401, and rollers 402 are installed at the bottom , the beam 401 is used to fix the positioning stand 3, and the roller 402 is used to move the support truss 4, together with the drilling rig 1, to a predetermined position when the drilling rig 1 changes locations.

[0034] In this embodiment, the positioning stand 3 is also equipped with wheels 302, and the positioning stand 3 is connected to the support truss 4 through a connecting piece 403. After the operation of the drilling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com