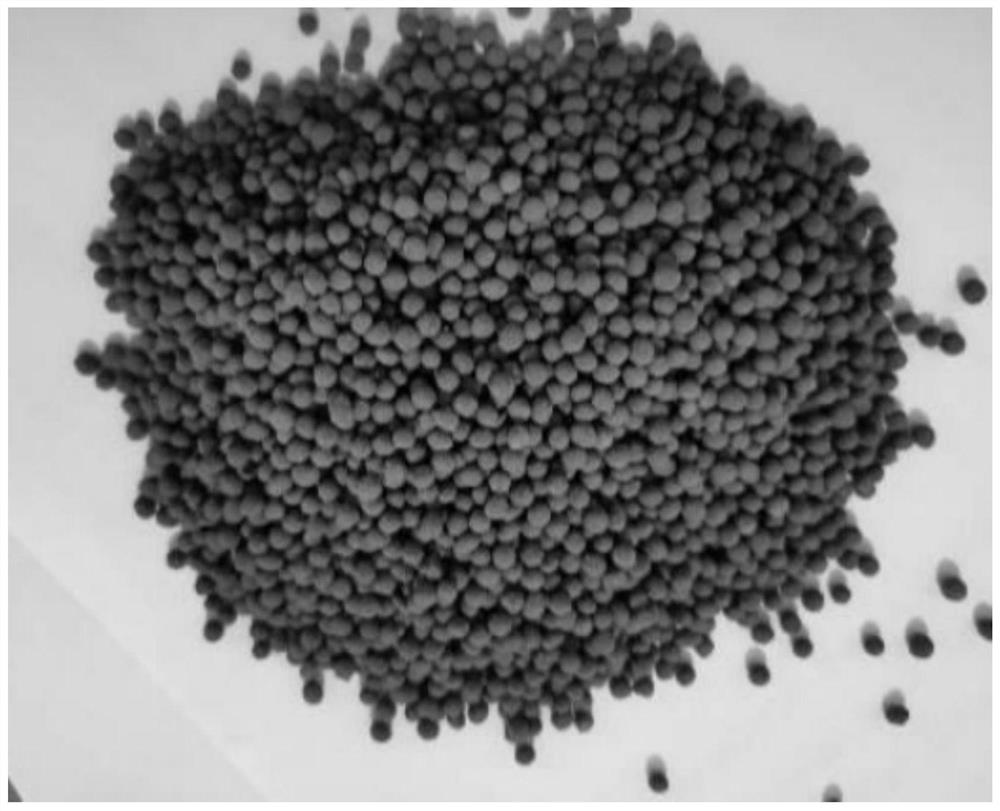

Biological ceramsite and preparation method thereof

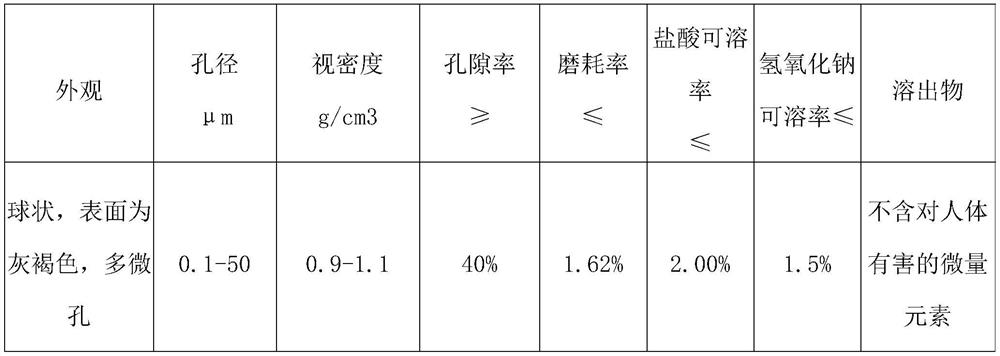

A technology of biological ceramsite and mixture, which is applied in ceramic products, sustainable biological treatment, chemical instruments and methods, etc., can solve the problem of low porosity of filter materials, and achieve the effect of high flexural strength, strong plasticity and not easy to break.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

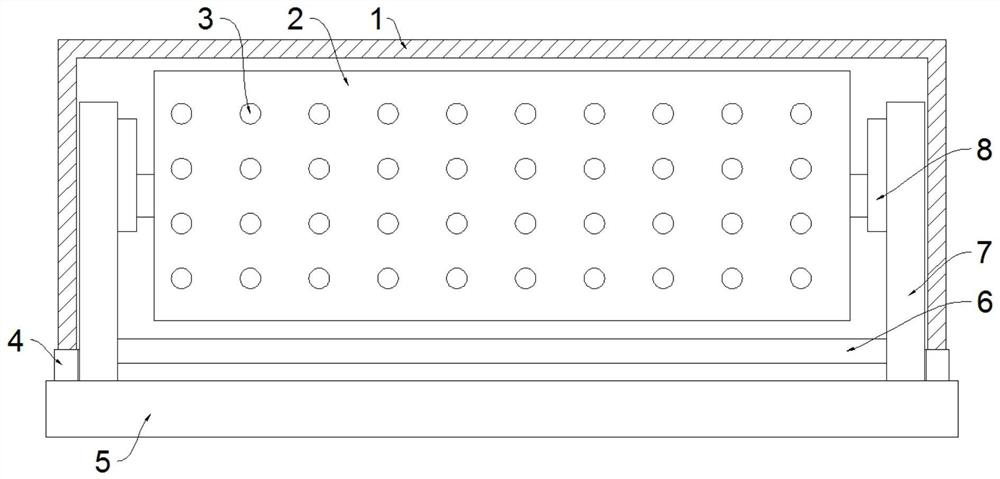

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: a kind of biological ceramsite, main material comprises kaolin and potassium feldspar; Auxiliary material comprises pore forming agent and binding agent;

[0029] The parts by weight of potassium feldspar, pore forming agent and binder are 27 parts of kaolin, 23 parts of potassium feldspar, 9 parts of flue-cured tobacco stem, and 1.3 parts of latex powder

Embodiment 2

[0030] The difference between Example 2 and Example 1 is that the parts by weight of kaolin, potassium feldspar, pore forming agent and binder are 28 parts of kaolin, 26 parts of potassium feldspar, 10 parts of flue-cured tobacco rod, and 2.7 parts of latex powder.

Embodiment 3

[0031] The difference between Example 3 and Example 1 is that the parts by weight of kaolin, potassium feldspar, pore forming agent and binder are 32 parts of kaolin, 29 parts of potassium feldspar, 11 parts of flue-cured tobacco rod, and 3.0 parts of latex powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com