Drilling gas extraction method capable of preventing damage to ground

A surface drilling and gas drainage technology, which is applied in the direction of gas discharge, earthwork drilling, drilling equipment, etc., can solve the problems of high cost, difficulty in L-shaped drilling construction, damage, etc., achieve high safety and improve gas drainage The effect, the effect of high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

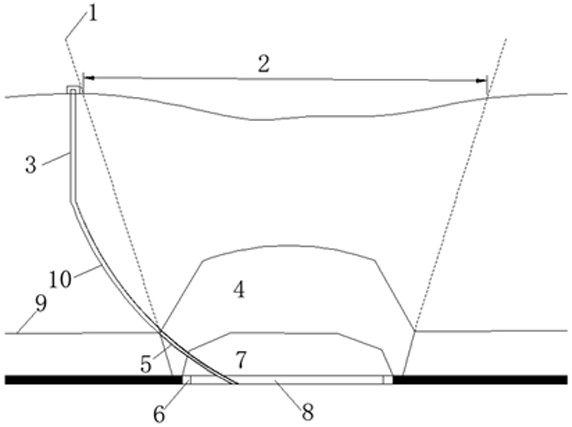

[0016] Before the coal seam is mined, start drilling at a distance of 3-5m from the edge of the surface mobile basin 2 near the return airway side 6 above the mined coal seam 8, and use a 241.3mm drill bit to drill vertically down to 30-50 m above the mined coal seam fissure zone 4 Stop at 50 m, then go down into the vertical rigid pipe 3; then make an inclination in the direction of 40-60° in the return airway, from the upper boundary line 9 of the mining coal seam collapse zone and the mining stress boundary on the side of the return airway 6 The junction of line 1 enters the mining coal seam fissure zone 4, and passes through the mining coal seam fissure zone 4 to enter the mining coal seam caving zone 7, so that the bottom of the drilling well is located in the range of 10-40 m from the inner return airway and enters the floor of the mining coal seam 8; The drilling section inclined to the junction of the upper boundary line 9 of the mining coal seam caving zone and the min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com