Process for combining seven-effect tube plate with falling-film evaporators

A falling-film evaporator and evaporator technology, applied in the directions of multi-effect evaporation, evaporator accessories, evaporation, etc., can solve the rising investment and production and maintenance costs of the evaporator group, the comprehensive cost has no competitive advantage, and the investment and maintenance costs increase, etc. problems, to achieve the effect of ensuring the service life, improving the effect of film cloth, and improving the ability to resist stress corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

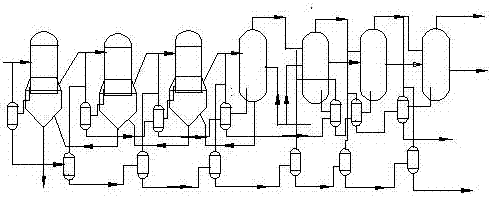

[0023] Such as figure 1 The seven-effect tube plate combined with the falling film evaporator process is combined effectively with the tube falling film evaporator and the plate falling film evaporator. At high temperature, the tube falling film evaporator is used to increase the effective temperature difference, which can ensure the evaporator In addition, the service life of the evaporator can be guaranteed. In specific implementation, the first, second and third effect evaporators and the fourth, fifth, sixth and seventh effect plate falling film evaporators are sequentially connected by pipelines. Among them, the first, second, and third effect evaporators are tube-type falling-film evaporators, and the fourth, fifth, sixth, and seventh-effect evaporators are plate-type falling-film evaporators, which can properly reduce the effective temperature difference and ensure that the evaporator At the same time, because the fog film separation flow area of the plate falling fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com