Reverse osmosis integration machine purification system

A purification system, integrated machine technology, applied in reverse osmosis, osmosis/dialysis water/sewage treatment, chemical instruments and methods, etc., can solve the problems of different service life of osmotic membranes, low osmotic separation efficiency, and high capital investment costs , to achieve the effect of low capital construction investment cost, improve water treatment efficiency, and reduce spare parts cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

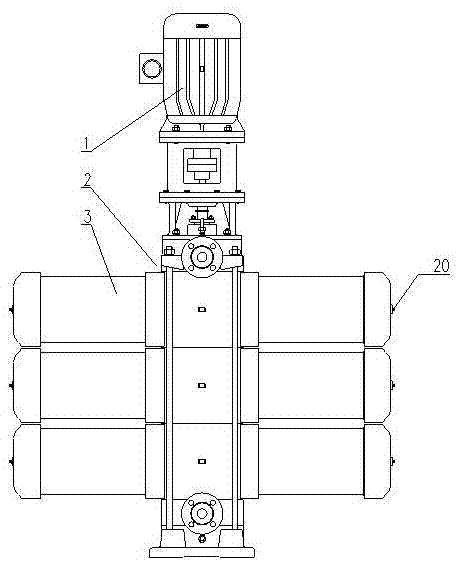

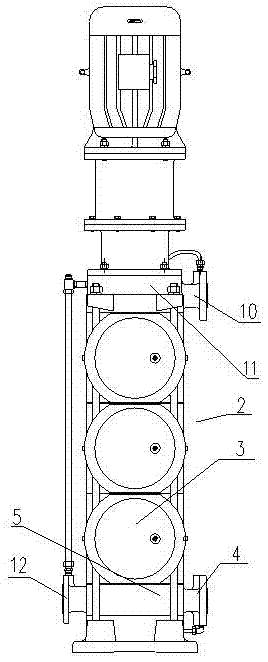

[0030] Such as figure 1 As shown, a reverse osmosis integrated purification system includes a prime mover 1, a separation purifier 2 connected to the prime mover 1, and a permeable membrane unit 3 or a unit group connected in parallel with the separation purifier 2. In this embodiment, the separation and purification machine 2 is connected in parallel with three permeation membrane unit groups, each permeation membrane unit group includes two permeation membrane units 3, and these two permeation membrane units 3 are connected in parallel on both sides of the separation and purification machine.

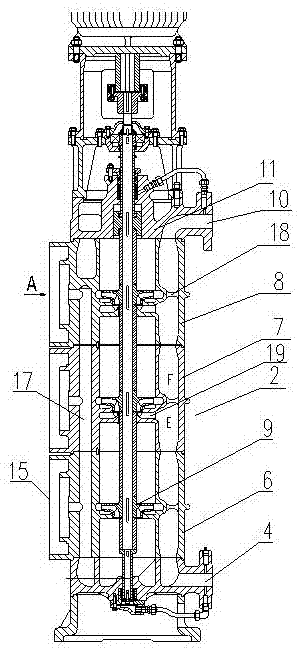

[0031] Such as Figure 2 to Figure 5 As shown, in this embodiment, the separation and purification machine 2 includes a water inlet section 5 with a sewage water inlet 4 and a clean water outlet 12, a first-stage conversion water separator 6, an intermediate conversion water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com