A kind of composite catalyst, preparation method and application of catalytic oxidation vocs

A composite catalyst, catalytic oxidation technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem that the activity cannot reach the noble metal oxide catalyst, catalytic oxidation temperature High cost, high cost, etc., to achieve the effect of simple and controllable preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

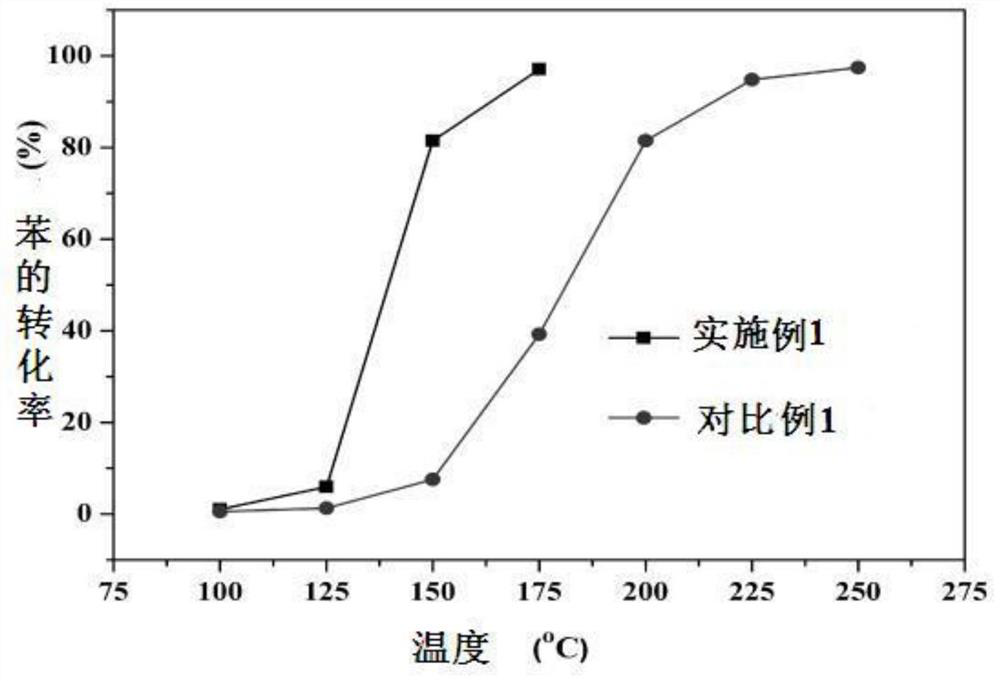

Embodiment 1

[0058] 1.801g Mn(CH 3 COO) 2 4H 2 O and 0.531g Ce(CH 3 COO) 3 1.5H 2 Dissolve O together in 10mL of deionized water to prepare a mixed solution; add 5.0g of 60 mesh Al to the mixed solution 2 o 3 Particles, oscillated at 50°C, impregnated with 300W ultrasonic for 25 minutes, dried at 110°C for 8 hours, and calcined at 600°C for 7 hours to obtain solid particles;

[0059] Place solid particles in a fixed bed, heat the bed to 200°C, -1 The hydrogen was purged for 60 min to prepare the Ce-Mn composite catalyst for catalytic oxidation of VOCs.

Embodiment 2~6

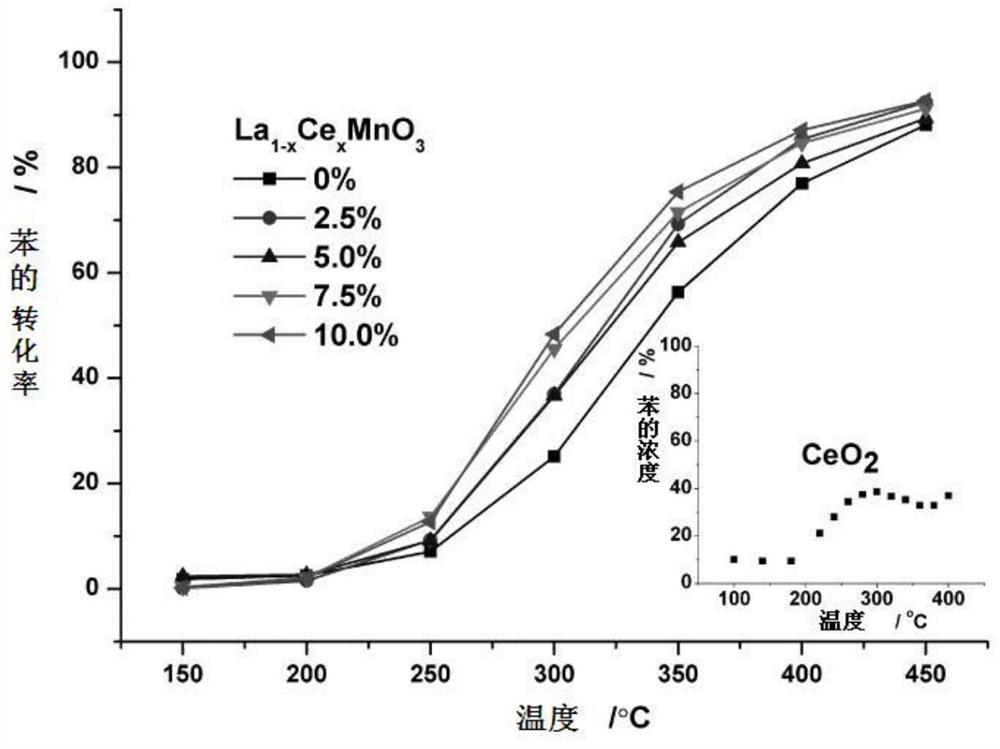

[0067] The cerium acetate Ce(CH 3 COO) 3 1.5H 2 O, manganese acetate Mn(CH 3 COO) 2 4H 2 O and lanthanum acetate La(CH 3 COO) 3 ·6H 2 Dissolve O together in 10mL of deionized water to prepare a mixed solution; add 5.0g of 60 mesh Al to the mixed solution 2 o 3 Particles, oscillated at 50°C, impregnated with 300W ultrasonic for 25 minutes, dried at 110°C for 8 hours, and calcined at 600°C for 7 hours to obtain solid particles;

[0068] Place solid particles in a fixed bed, heat the bed to 200°C, -1 The hydrogen purging of 60min, the preparation of catalytic oxidation of VOCs La 1-x Ce x MnO 3 ;

[0069] For the addition of cerium acetate, manganese acetate or lanthanum acetate, according to the molecular formula La 1-x Ce x MnO 3 The values of x are different, and they are added separately, and the value of x is 0 (LaMnO 3 ), 2.5% (La 0.975 Ce 0.025 MnO 3 ), 5.0% (La 0.95 Ce 0.05 MnO 3 ), 7.5% (La 0.925 Ce 0.075 MnO 3 ), 10.0% (La 0.9 Ce 0.1 MnO 3...

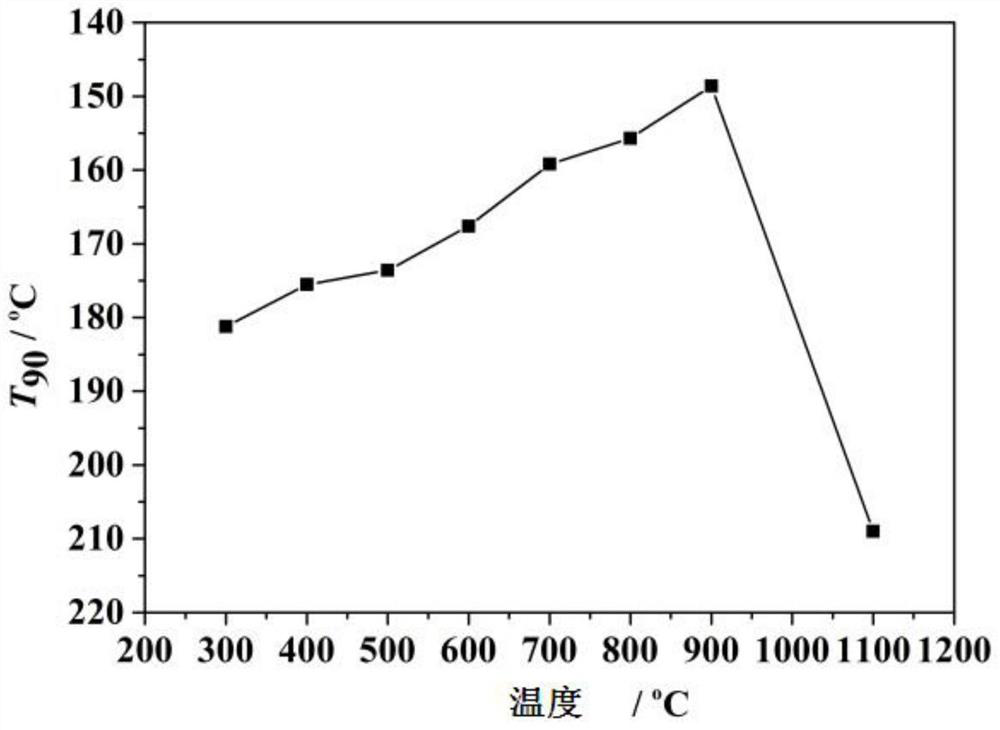

Embodiment 7~14

[0076] 1.801g Mn(CH 3 COO) 2 4H 2 O and 0.531g Ce(CH 3 COO) 3 1.5H 2 Dissolve O together in 10mL of deionized water to prepare a mixed solution; add 5.0g of 60 mesh Al to the mixed solution 2 o 3 Particles, oscillating at a constant temperature of 50°C and impregnated with 300W ultrasonic for 25 minutes, dried at 110°C for 8 hours, and calcined at a specific calcination temperature for 7 hours to obtain solid particles;

[0077] Place solid particles in a fixed bed, heat the bed to 200°C, -1 Hydrogen purging for 60min to prepare a Ce-Mn composite catalyst that catalyzes the oxidation of VOCs;

[0078]The calcination temperatures are respectively 300°C, 400°C, 500°C, 600°C, 700°C, 800°C, and 900°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com