Composite catalyst for catalytically oxidizing VOCs, preparation method and uses thereof

A composite catalyst, catalytic oxidation technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. The problems of high cost and high cost are achieved, and the effect of the preparation method is simple and controllable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

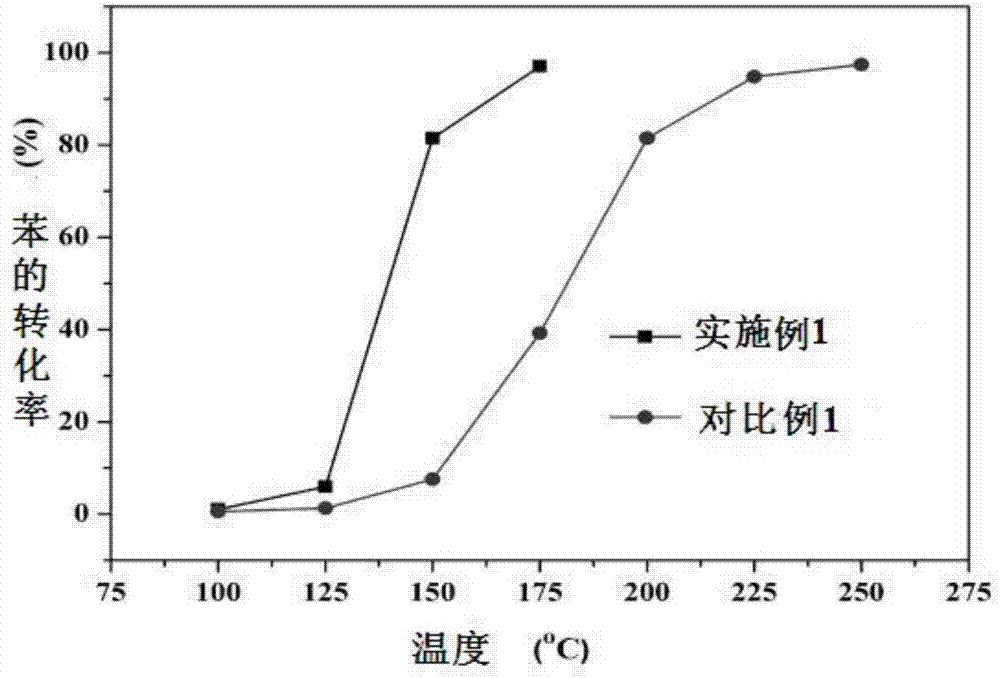

Embodiment 1

[0058] 1.801g Mn(CH 3 COO) 2 4H 2 O and 0.531g Ce(CH 3 COO) 3 1.5H 2 Dissolve O together in 10mL of deionized water to prepare a mixed solution; add 5.0g of 60 mesh Al to the mixed solution 2 o 3 Particles, oscillated at 50°C, impregnated with 300W ultrasonic for 25 minutes, dried at 110°C for 8 hours, and calcined at 600°C for 7 hours to obtain solid particles;

[0059] Place solid particles in a fixed bed, heat the bed to 200°C, -1 The hydrogen was purged for 60 min to prepare the Ce-Mn composite catalyst for catalytic oxidation of VOCs.

Embodiment 2~6

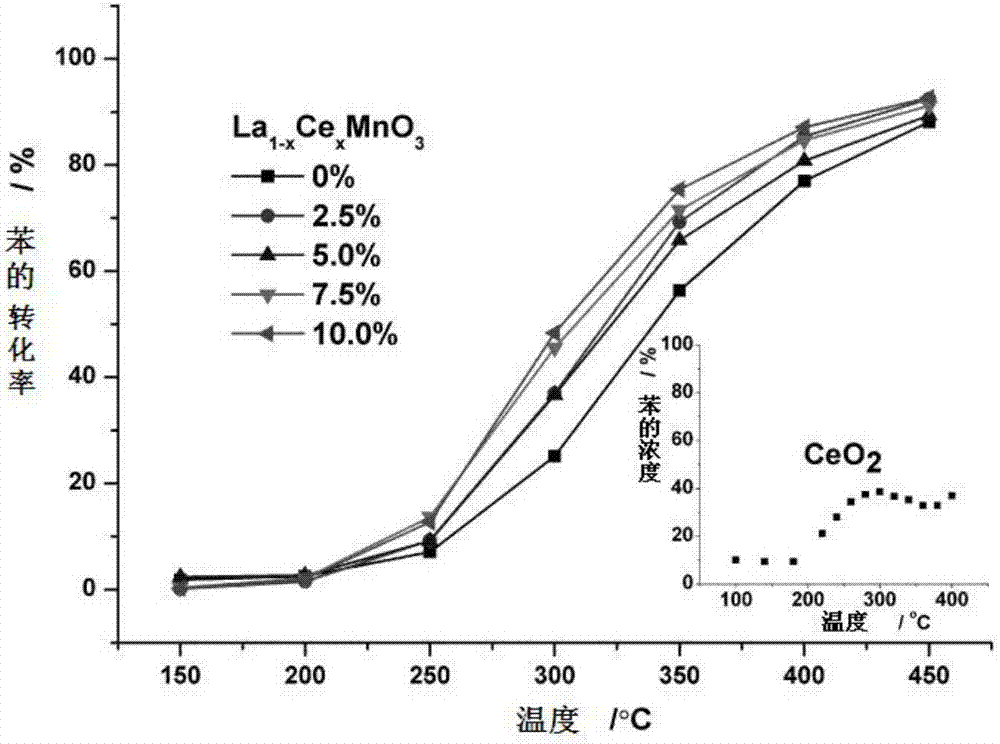

[0067] The cerium acetate Ce(CH 3 COO) 3 1.5H 2 O, manganese acetate Mn(CH 3 COO) 2 4H 2 O and lanthanum acetate La(CH 3 COO) 3 ·6H 2 Dissolve O together in 10mL of deionized water to prepare a mixed solution; add 5.0g of 60 mesh Al to the mixed solution 2 o 3 Particles, oscillated at 50°C, impregnated with 300W ultrasonic for 25 minutes, dried at 110°C for 8 hours, and calcined at 600°C for 7 hours to obtain solid particles;

[0068] Place solid particles in a fixed bed, heat the bed to 200°C, -1 The hydrogen purging of 60min, the preparation of catalytic oxidation of VOCs La 1-x Ce x MnO 3 ;

[0069] For the addition of cerium acetate, manganese acetate or lanthanum acetate, according to the molecular formula La 1-x Ce x MnO 3 The values of x are different, and they are added separately, and the value of x is 0 (LaMnO 3 ), 2.5% (La 0.975 Ce 0.025 MnO 3 ), 5.0% (La 0.95 Ce 0.05 MnO 3 ), 7.5% (La 0.925 Ce 0.075 MnO 3 ), 10.0% (La 0.9 Ce 0.1 MnO 3...

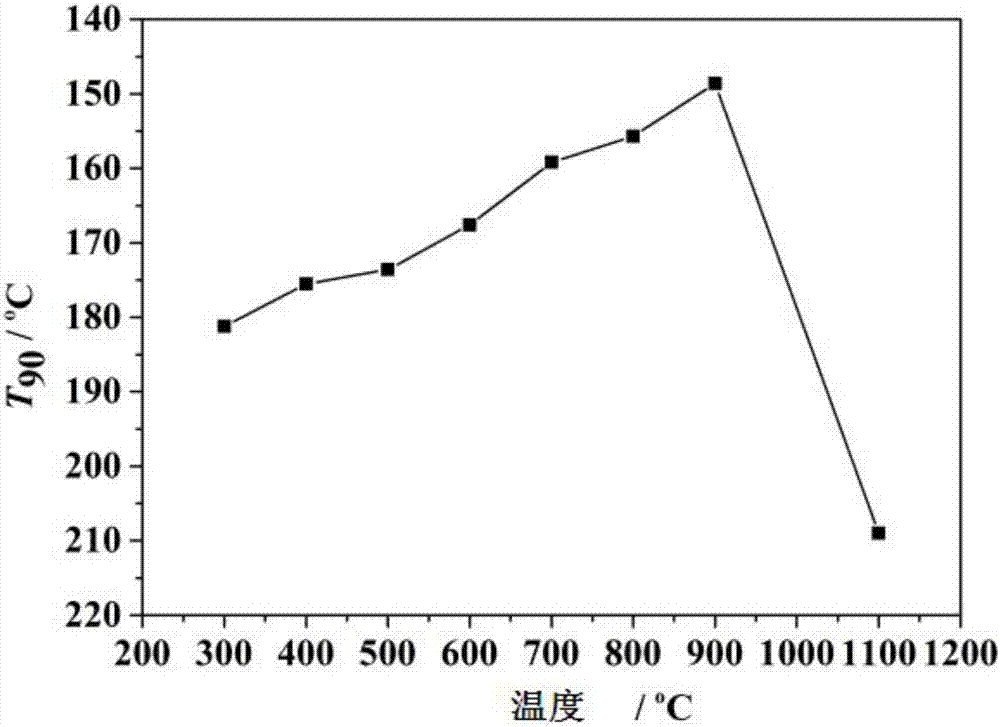

Embodiment 7~14

[0076] 1.801g Mn(CH 3 COO) 2 4H 2 O and 0.531g Ce(CH 3 COO) 3 1.5H 2 Dissolve O together in 10mL of deionized water to prepare a mixed solution; add 5.0g of 60 mesh Al to the mixed solution 2 o 3 Particles, oscillating at a constant temperature of 50°C and impregnated with 300W ultrasonic for 25 minutes, dried at 110°C for 8 hours, and calcined at a specific calcination temperature for 7 hours to obtain solid particles;

[0077] Place solid particles in a fixed bed, heat the bed to 200°C, -1Hydrogen purging for 60min to prepare a Ce-Mn composite catalyst that catalyzes the oxidation of VOCs;

[0078] The calcination temperatures are respectively 300°C, 400°C, 500°C, 600°C, 700°C, 800°C, and 900°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com