Dotting retractable pen cap structure

A retractable pen and pen cover technology, which is applied to strike tools, center guns, manufacturing tools, etc., can solve the problems of high price, single scope of application, inability to apply to engines, etc., and achieve the effects of low cost, expanded application scope, and clear dots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

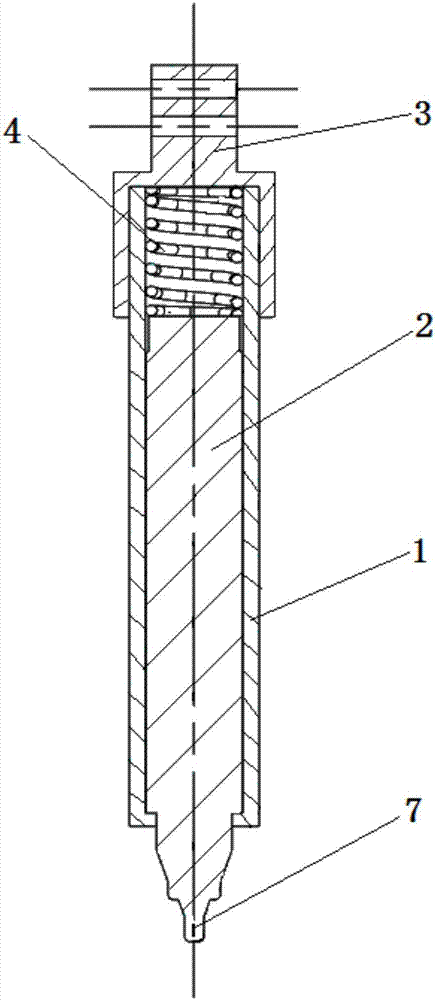

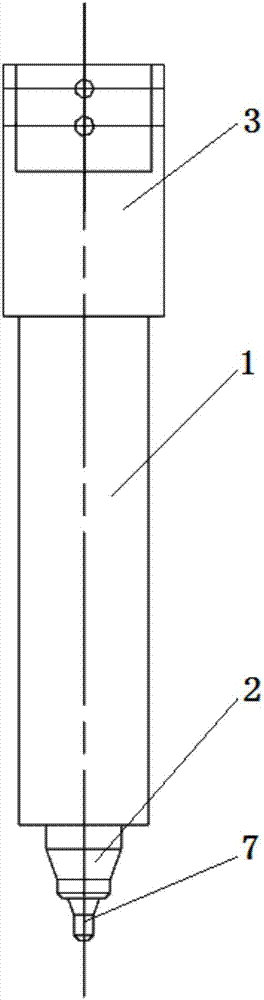

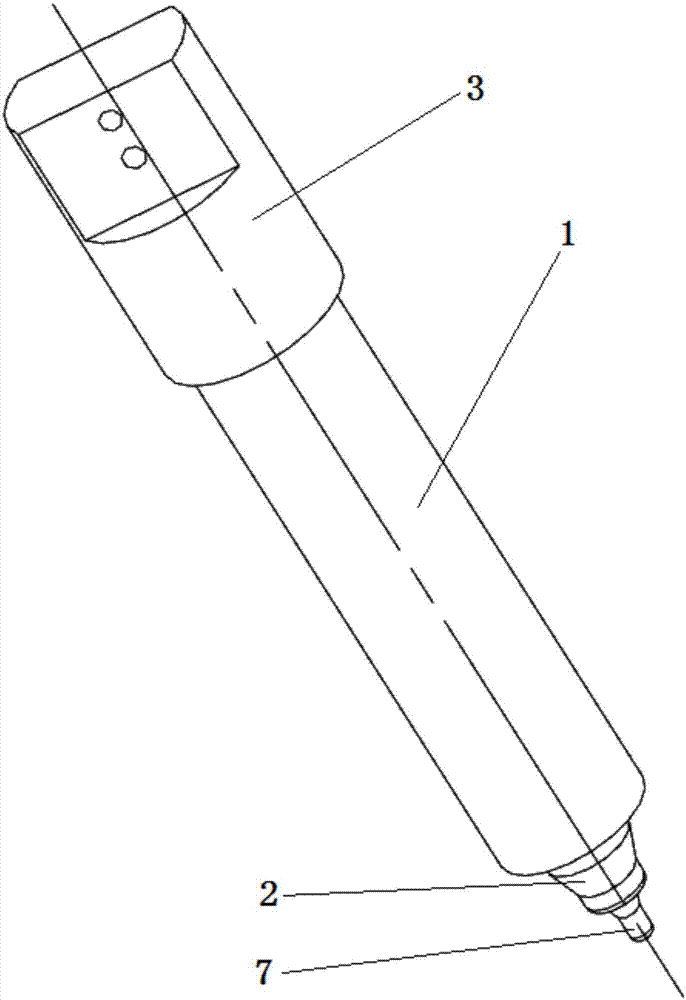

[0024] refer to Figure 1-6 , a dotting retractable pen cap structure of the present invention, comprising a pen cap 1 of a hollow structure and a dotting pen 2 inserted into the inner cavity of the pen cap 1 and capable of reciprocating up and down relative to the pen cap 1 to realize dotting parts, wherein the dotting pen 2. It is made of a finished product pen with ink in its inner cavity. There is a clearance fit between the dotting pen 2 and the pen case 1. A clamping piece that can be connected with the dotting machine on the engine assembly line and whose position can be adjusted is set on the top of the pen case 1. 3. The pen cover 1 is in contact with the clamping part 3. The axial relative contact between the pen cover 1 and the clamping part 3 can be adjusted to change the amount of contact between the two. The pen cover 1 between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com