A linear guide rail at the end of a robot

A linear guide, robot technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of increasing the use, maintenance and repair costs of robots, assembly difficulties, and high requirements for machining accuracy, so as to reduce production and maintenance costs and avoid partial wear and tear. Serious effects with low requirements on machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the following detailed description, numerous specific details are set forth in order to provide a thorough understanding of the present invention. However, it will be understood by those skilled in the art that the present invention may be practiced without these specific details. In other instances, well-known methods, procedures, components and circuits have not been described in detail so as not to obscure the present invention.

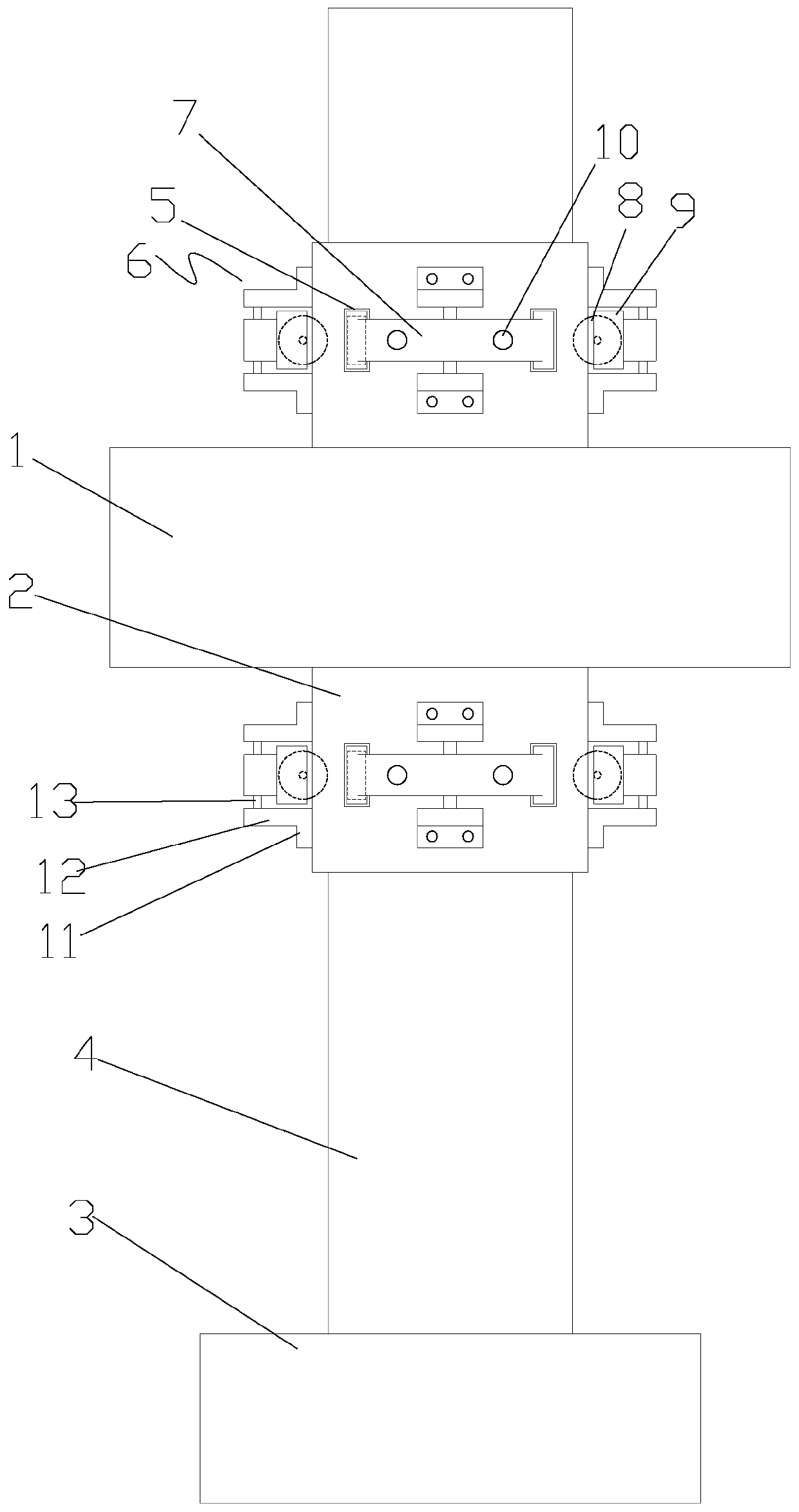

[0021] Such as figure 1 As shown, according to the embodiment of the present invention, the linear guide rail at the end of the robot includes a slider 2 connected to the end 1 of the robot and a track 4 connected to the frame 3 of the robot. The track 4 is a rectangular column, and the slider 2 is slidingly sleeved on the rectangular column. In addition, each side of the slider 2 is provided with two bearing holes 5 along the width direction, the slider 2 is fixedly provided with a mounting seat 6, and a connecting frame 7 is swingably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com