An anti-leakage monitoring system for chlorine storage tanks

A monitoring system and a storage tank technology are applied in the field of chlorine gas storage tank anti-leakage monitoring systems, which can solve the problems that chlorine gas storage tanks cannot be found at the first time, hidden dangers of enterprise safety operation, low degree of automation, etc., so as to facilitate monitoring. And on-site processing, processing mobility is strong, and the effect is conducive to production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

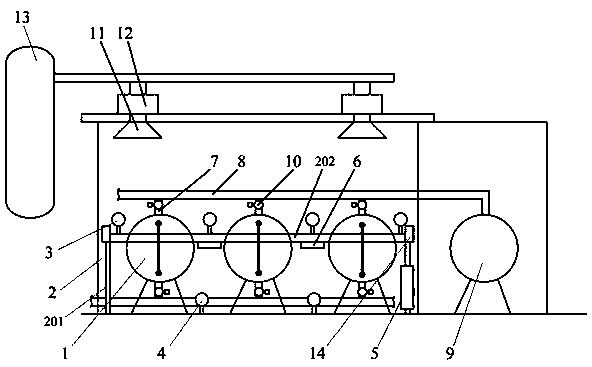

[0016] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes several chlorine gas storage tanks 1 fixedly installed in the warehouse, and a frame body 2 is arranged around the chlorine gas storage tank 1, and the frame body 2 includes four support columns 201, and cross beams 202 connecting the four support columns 201 The inside of the crossbeam 202 is provided with a cavity for storing lines; the left and right sides of the chlorine gas storage tank 1 are respectively provided with a first-level chlorine gas leakage detector 3, and the first-level chlorine gas leakage detector 3 is fixed on the crossbeam 202; A secondary chlorine gas leakage detector 4 is arranged between the chlorine gas storage tanks 1, and the secondary chlorine gas leakage detector 4 is fixed on the bottom surface of the warehouse; A second fan 6 is arranged between the chlorine gas storage tanks 1, and the second fan 6 is fixed on the lower end of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com