Method of achieving zero-emission to high salt wastewater generated in industrial production

A high-salt wastewater, zero-discharge technology, applied in the field of zero-discharge of high-salt wastewater, can solve the problem of lack of treatment technology for reverse osmosis concentrated water, and achieve the effect of improving wastewater concentration efficiency, reducing scaling and corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

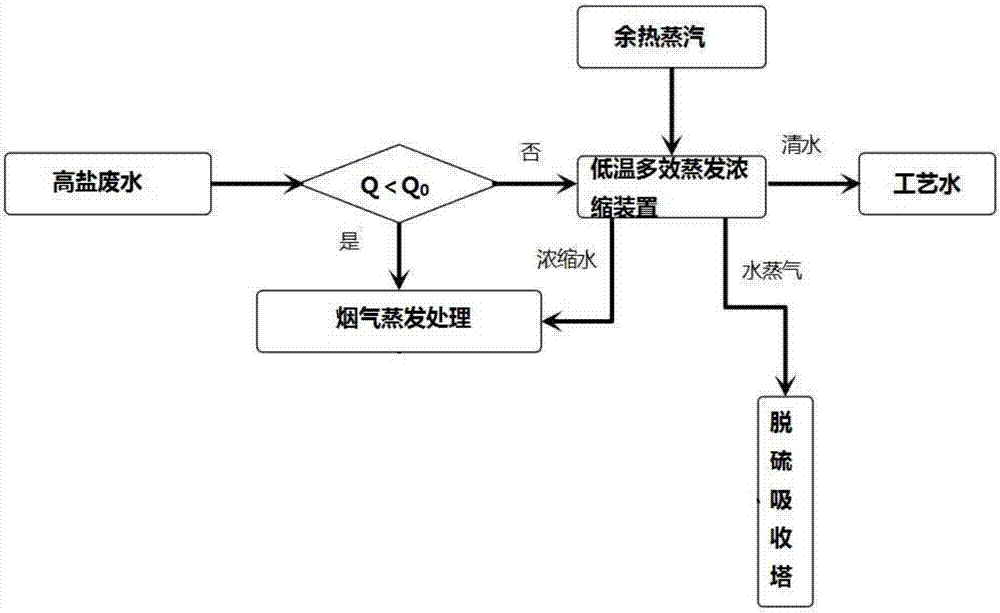

[0034] This embodiment provides a method for zero discharge of high-salt wastewater produced in industrial production, such as figure 1 As shown, when the discharge quantity Q of high-salt wastewater per unit time in industrial production is less than or equal to the quantity Q of high-salt wastewater that can be evaporated by the flue gas treatment device per unit time 0 When the high-salt wastewater is directly treated with flue gas evaporation;

[0035] When the amount Q of high-salt wastewater discharged per unit time in industrial production is greater than the amount Q of high-salt wastewater that can be evaporated per unit time by the flue gas treatment device 0 When the high-salt wastewater is concentrated by a low-temperature multi-effect evaporation concentration device, it is then evaporated and concentrated;

[0036] The heating steam of the low-temperature multi-effect evaporation and concentration device adopts the waste heat steam in industrial production. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com