Production process for controlling large inclusions in acid-resistant pipeline steel

A production process and pipeline steel technology, applied in the field of metallurgy, can solve problems such as increasingly stringent service environment requirements, affecting the performance of steel plates, unqualified flaw detection and inclusion inspection, etc., to improve internal quality, good deformation ability, and improve purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

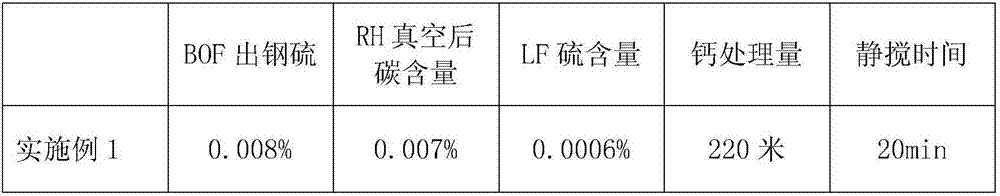

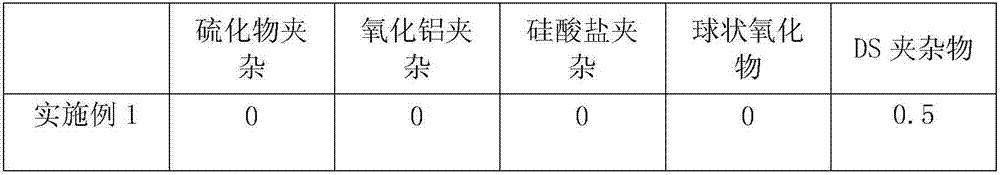

Embodiment 1

[0020] This embodiment is a production process for controlling large inclusions in acid-resistant pipeline steel, including the following steps:

[0021] (1) The weight percentage composition of pipeline steel is: C: 0.040%, Si 0.30%, Mn: 1.30%, P: 0.013%, S: 0.0010%, Nb: 0.070%, Ti: 0.020%, Ca: 0.0040%, Al: 0.050%, Cu: 0.30%, Ni: 0.30%, Cr: 0.30%, the balance is Fe;

[0022] (2) The desulfurization station uses lime and magnesium powder for composite desulfurization, and the slag is clean after desulfurization to ensure that the sulfur behind the converter is less than 100ppm;

[0023] (3) After the molten steel reaches RH, the vacuum degree is less than or equal to 3mbar for decarburization, and after the carbon is less than 0.01%, it is alloyed. After the alloying is completed, the vacuum is maintained. No alloying operation is performed during the vacuum treatment;

[0024] (Iv) LF uses lime and aluminum deoxidizer for desulfurization operation, desulfurization to 5-8ppm, to ensur...

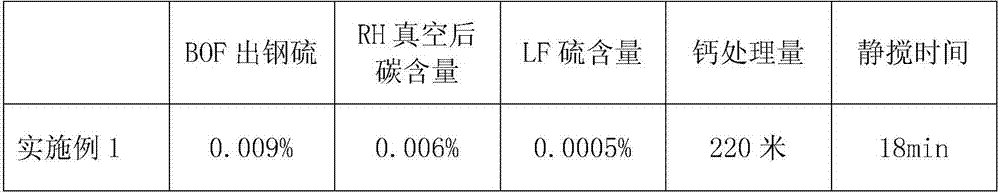

Embodiment 2

[0033] This embodiment is a production process for controlling large inclusions in acid-resistant pipeline steel, including the following steps:

[0034] (1) The weight percentage composition of pipeline steel is: C: 0.020%, Si 0.10%, Mn: 1.0%, P: 0.01%, S: 0.0010%, Nb: 0.030%, Ti: 0.006%, Ca: 0.0040%, Al: 0.015%, Cu: 0.10%, Ni: 0.10%, Cr: 0.10%, the balance is Fe;

[0035] (2) The desulfurization station uses lime and magnesium powder for composite desulfurization, and the slag is clean after desulfurization to ensure that the sulfur behind the converter is less than 100ppm;

[0036] (3) After the molten steel reaches RH, the vacuum degree is less than or equal to 3mbar for decarburization. After the carbon is less than 0.01%, the alloying treatment is carried out. After the alloying is completed, the vacuum is maintained. No alloying operation is carried out during the vacuum treatment;

[0037] (Iv) LF uses lime and aluminum deoxidizer for desulfurization operation, desulfurization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com