Method for installing prefabricated pier column component of prefabricated bridge

An installation method and prefabricated technology are applied in the field of prefabricated pier and column member installation of prefabricated bridges, which can solve the problems of inability to precisely control the splicing and positioning of prefabricated piers and columns, and achieve a simple and convenient adjustment method, shorten the installation period, and improve the installation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

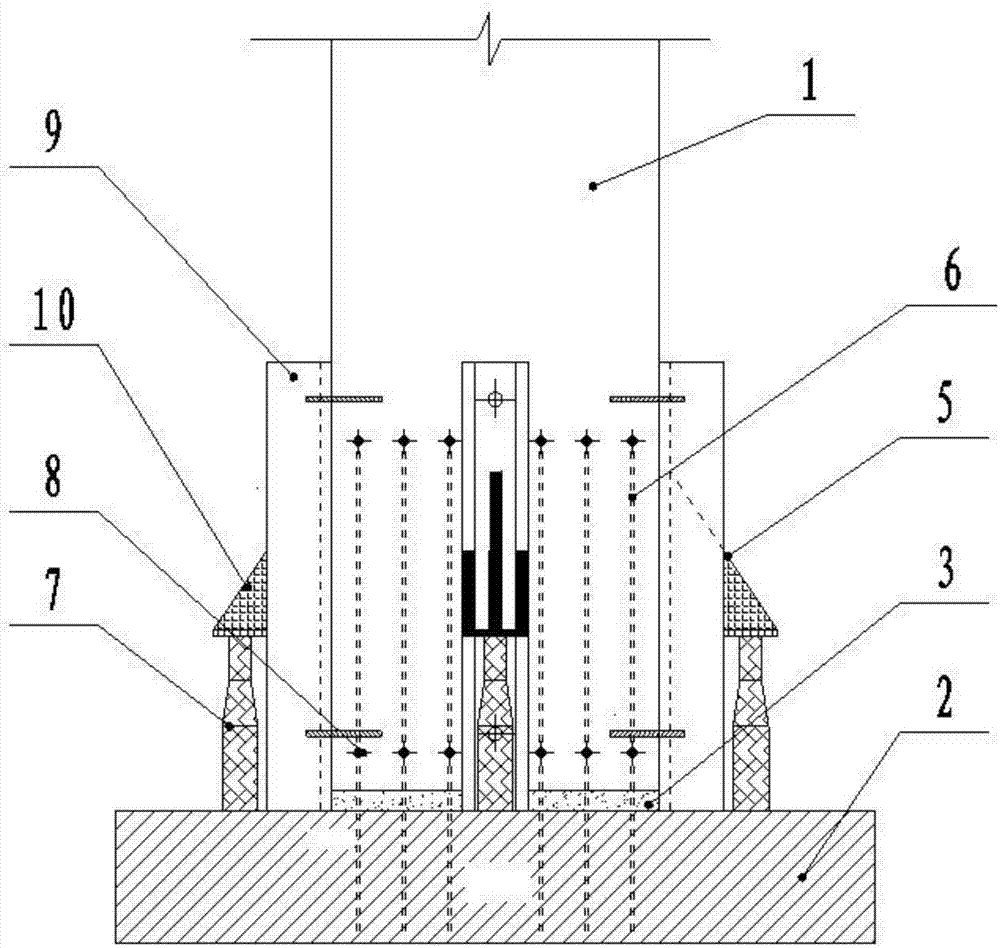

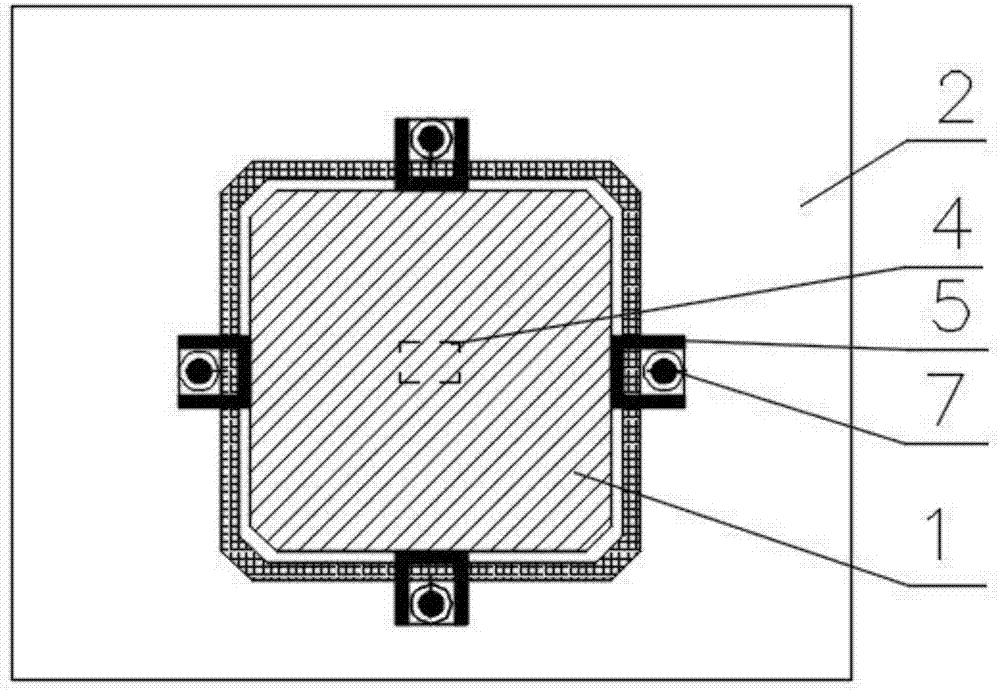

[0030] Such as Figure 1-2 As shown, the present invention is a prefabricated bridge pier component installation method, the prefabricated pier 1 is accurately assembled on the cap 2 poured in advance, and the prefabricated pier 1 and cap 2 are in the same structure form, the butt surface of the prefabricated pier column to be installed on the cap 2 is pre-planted with reserved steel bars 6, and the end of the prefabricated pier column 1 is also pre-planted with an F-shaped butt sleeve, and between the prefabricated pier column 1 and the cap 2 The space is connected and supported through the pier column grout 3, and the steel bar 6 reserved for the cap 2 is inserted into the pre-buried connection sleeve in the prefabricated pier column 1, and the connection is performed by pressure grouting, including steps:

[0031] Before the prefabricated pier column 1 is in place, the docking marks are respectively marked on the bottom end surface of the prefabricated pier column 1 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com