Turbocharger with variable axial section

A turbocharger, axial technology, used in machines/engines, internal combustion piston engines, mechanical equipment, etc., can solve the problem that the nozzle ring blades cannot adapt to the high temperature exhaust of the engine, the reliability of the variable nozzle ring is poor, and the manufacturing accuracy is high. problems, to achieve the effect of fast and sensitive adjustment process, improved driving safety performance, and low material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

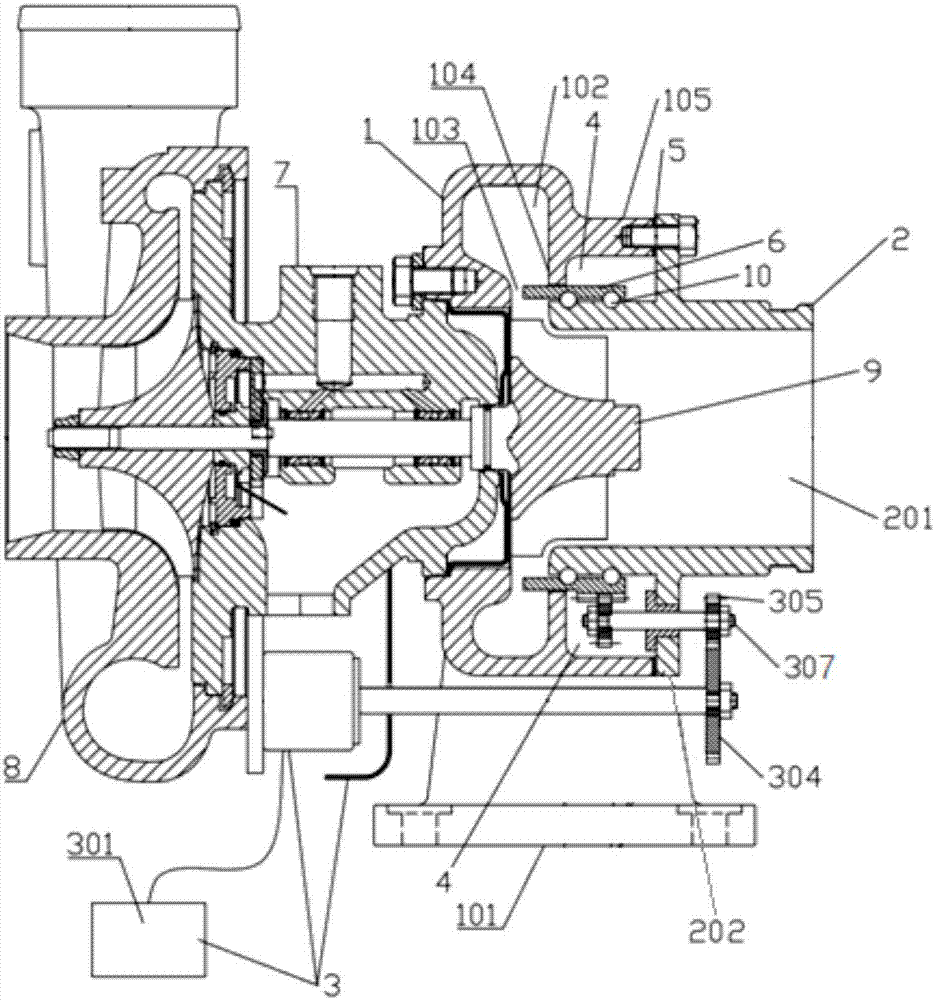

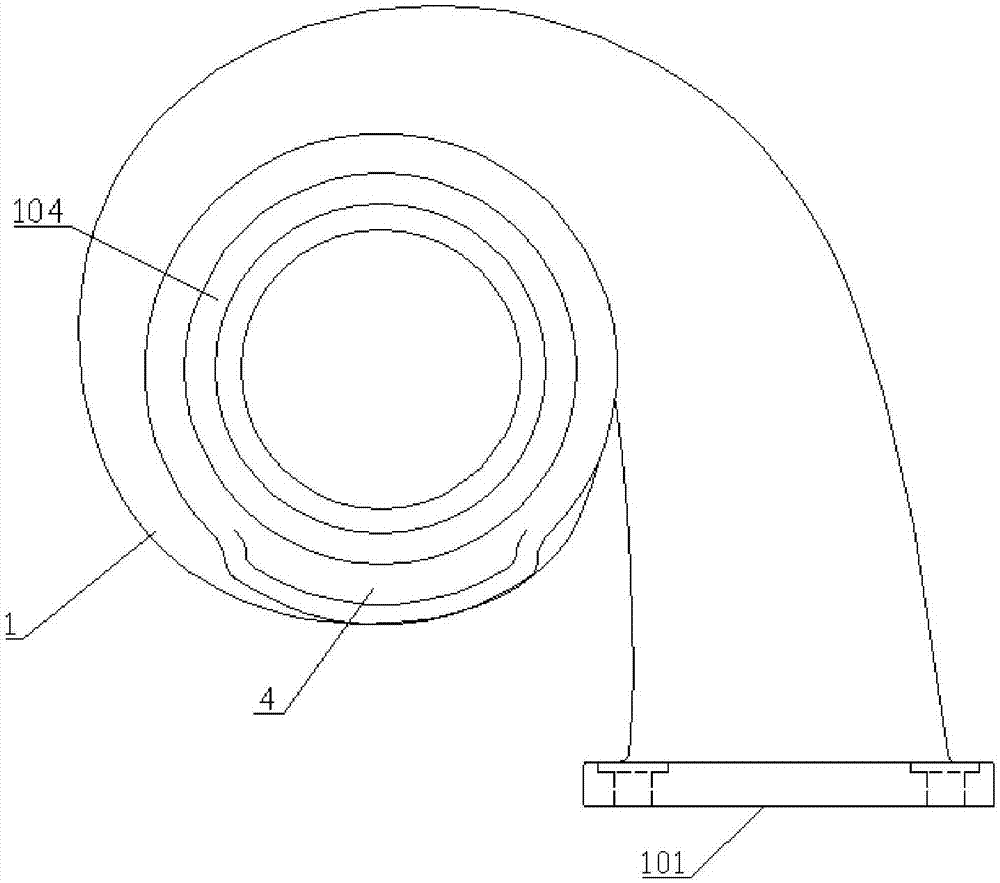

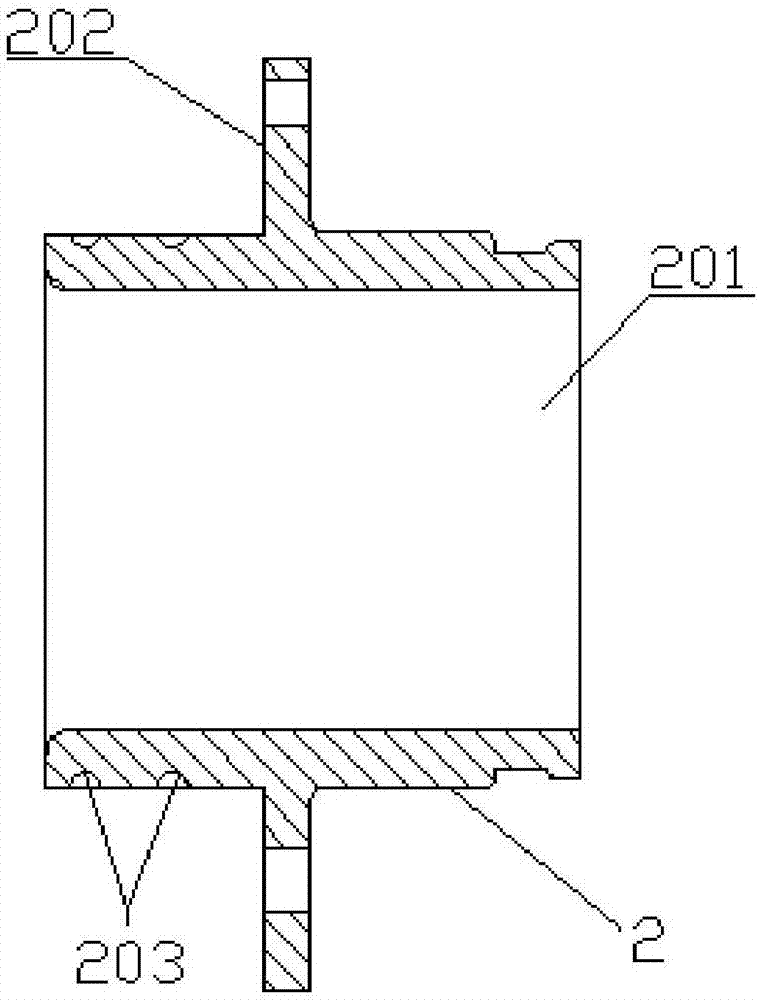

[0039] like figure 1 Shown is an axially variable cross-section turbocharger, which includes a compressor 8 , an intermediate body 7 , a turbine casing 1 and an exhaust casing 2 connected in sequence. like figure 2 As shown, the turbine casing 1 is provided with an exhaust gas inlet 101 , and inside is provided with a turbine 9 and a vortex channel 102 communicating with the exhaust gas inlet 101 and the turbine 9 respectively. One end of the exhaust casing 2 is provided with an exhaust outlet 201, and a cavity 4 and a movement control ring 6 are arranged between the inner side of the turbine casing 1 and the outer side of the exhaust casing 2, and one end of the movement control ring 6 is located Between the pipe flow channel 102 and the turbine 9, the other end is located in the cavity 4, and the turbocharger also includes an electric control actuator 3 connected to the moving control ring 6, and the electric control actuator 3 drives the moving control ring 6 along the T...

Embodiment 2

[0046] In this embodiment, the included angle between the second rolling chute 601 and the central axis of the mobile control ring 6 is 15°, and the rest are the same as in Embodiment 1.

Embodiment 3

[0048] In this embodiment, the included angle between the second rolling chute 601 and the central axis of the mobile control ring 6 is 75°, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com