Combined thermal insulation bolt connection structure

A technology for connecting structures and piston bolts, applied in the directions of pistons, engine components, machines/engines, etc., can solve problems such as increased design, processing difficulty, increased tensile load, and aluminum body cracking, etc., to avoid thermal load increase, The effect of reducing the contact stress and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

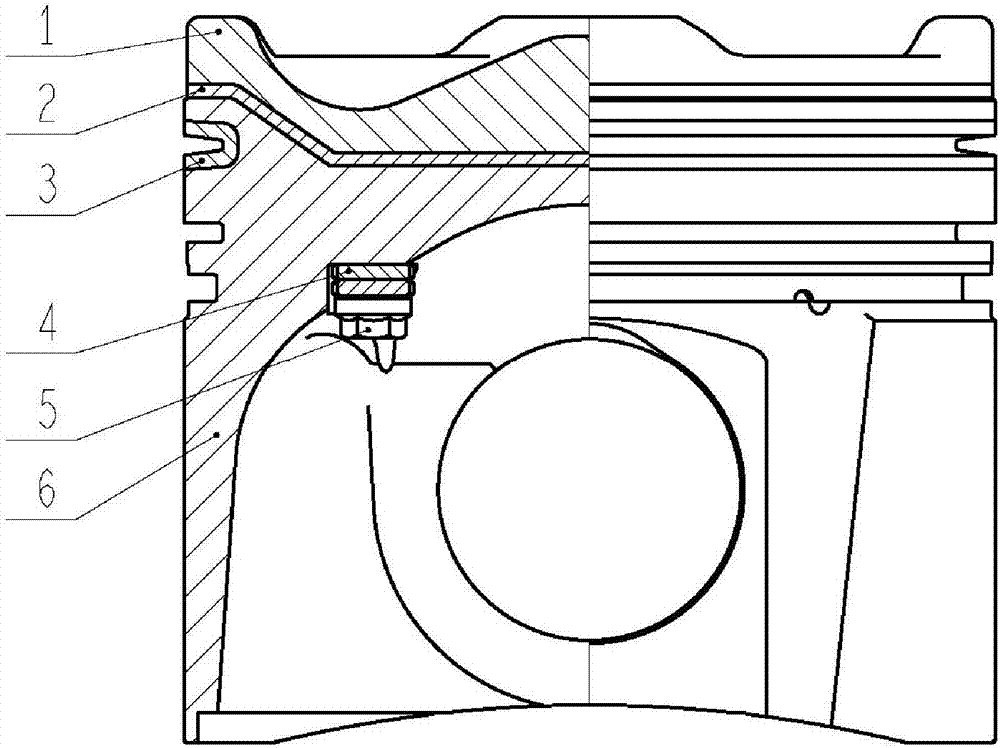

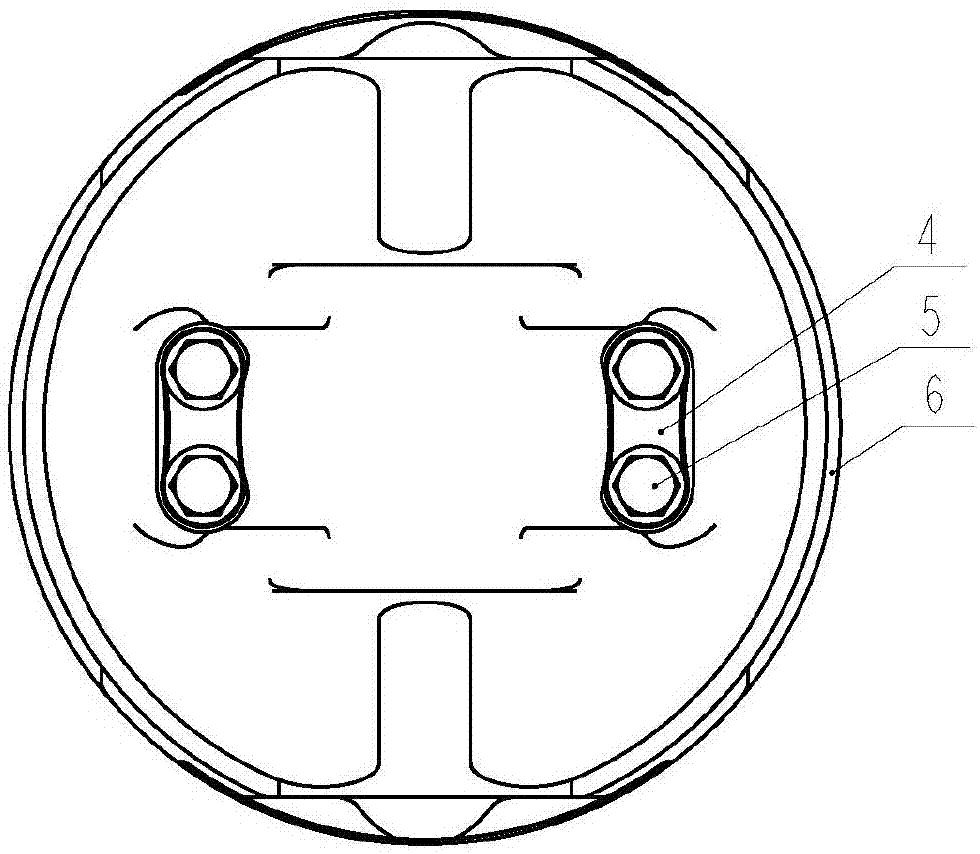

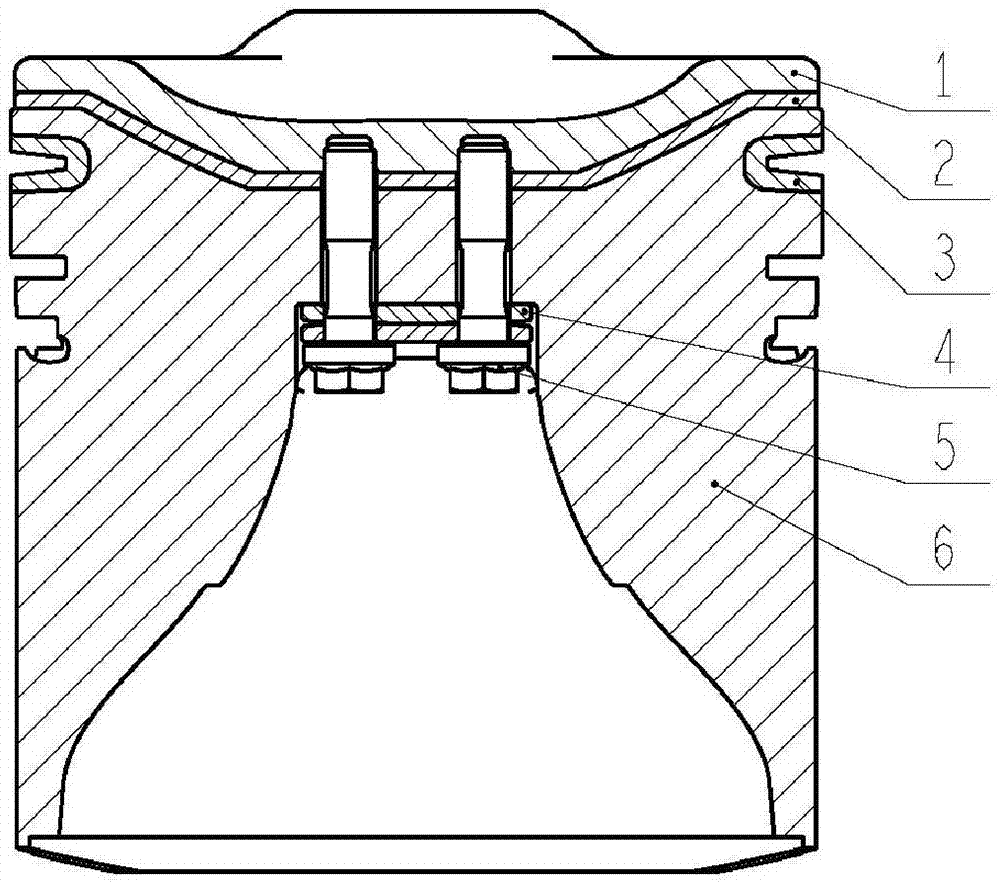

[0028] A combined insulation piston bolt connection structure, such as Figures 1 to 5 As shown, it includes piston steel top 1, metal heat insulation pad 2, insert ring 3, elastic combined gasket 4, bolt 5 and aluminum body 6;

[0029] The metal heat insulating pad 2 is arranged between the contact surface of the piston steel top 1 and the aluminum body 6 , and the metal heat insulating pad 2 is used to isolate the heat conducted from the piston steel top 1 to the aluminum body 6 .

[0030] The piston steel top 1 is provided with bolt holes for bolt fastening, the metal heat insulating pad 2 and the aluminum body 6 are provided with through holes for passing through the bolts, the pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com