Buffering self-electricity-generating type wave propeller

A self-generating and propulsion technology, applied in ocean energy power generation, engine components, machines/engines, etc., can solve the problems of short endurance, high cost, poor economy, etc., improve navigation ability, reduce fatigue damage, and increase service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

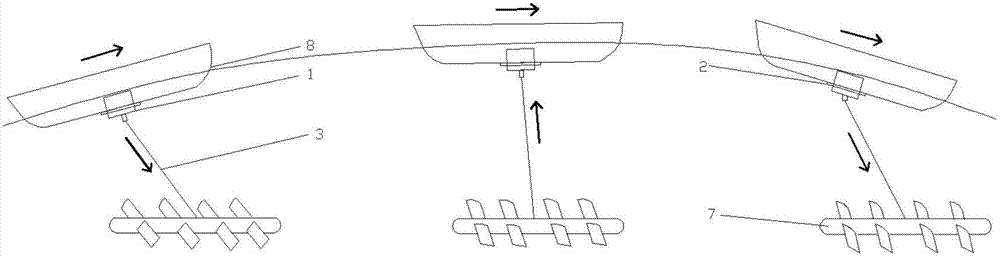

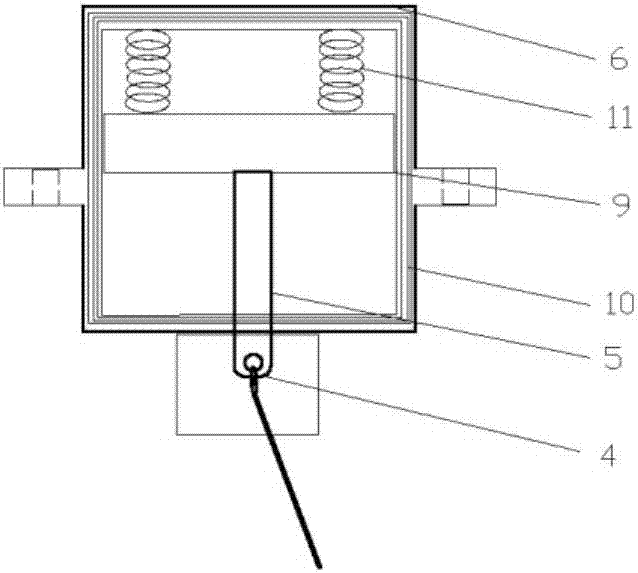

[0044] The structural principle of the present invention is, firstly, the buffer self-generating device 1 of the wave propeller is installed on the bottom of the upper floating body 8 through the fixing flange 2, and then the flexible cable 3 of the power device 7 is connected to the buffer through the locking buckle 4. From the lower end of the transmission connecting rod 5 of the power generating device 1 , finally, the electric energy output wire 6 buffered from the power generating device 1 is connected to the power storage device inside the floating body 8 .

[0045] According to the above structural principle, a buffer self-generating wave propeller: buffer self-generating device 1, flexible cable 3, and power device 7.

[0046] The flexible cable 3 is made of a steel wire rope, and the power unit 7 is made of a position-limiting mechanism in the middle and a swinging hydrofoil.

[0047] The buffer self-generating device 1 is connected to the floating body 8 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com