Indoor heating and ventilation boiler capable of automatically removing ash

An automatic removal and ash slag technology, applied in lighting and heating equipment, etc., can solve problems such as reducing work efficiency, affecting the effect of coal combustion, and unable to automatically clean coal slag, and achieving the effect of improving combustion and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

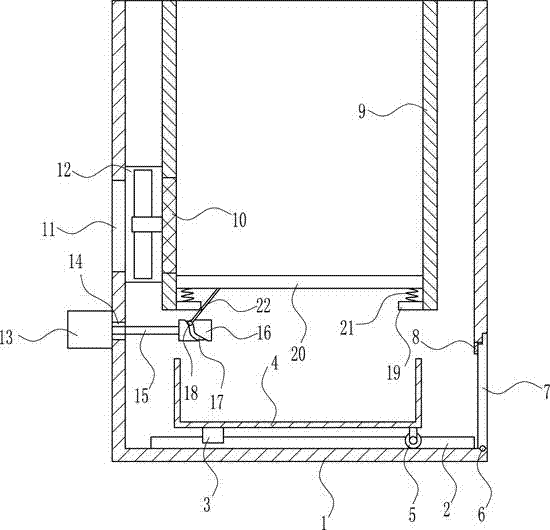

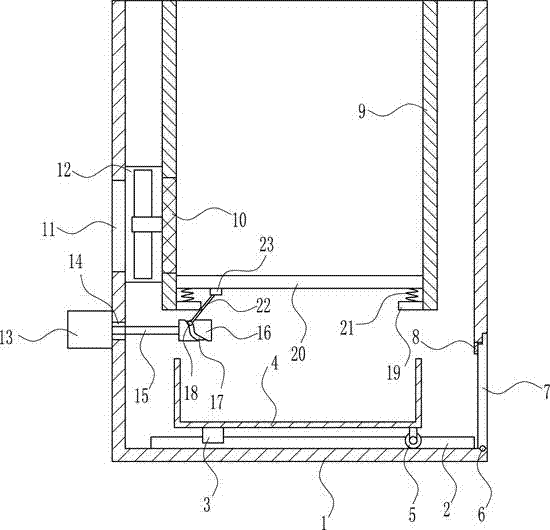

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

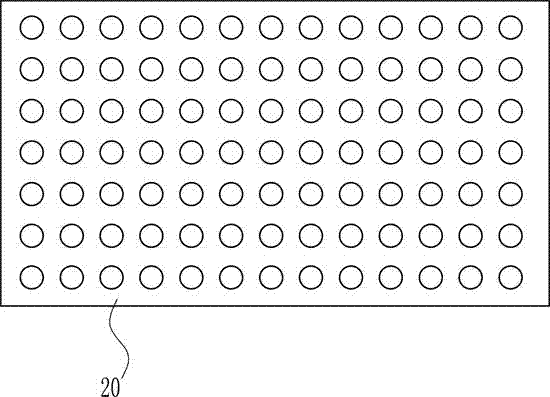

[0029] A general boiler for indoor heating that automatically removes ash, such as Figure 1-7 As shown, it includes an outer furnace 1, a slide rail 2, a slider 3, a slag receiving tray 4, a roller 5, a first rotating shaft 6, an iron cover 7, a magnet 8, an inner furnace 9, a dust screen 10, an induced draft fan 12, First motor 13, second rotating shaft 15, cylindrical cam 16, block 18, stopper 19, fire grate 20, spring 21 and swing bar 22, the bottom level in the outer furnace 1 is provided with slide rail 2, slide rail 2 is connected with the outer furnace 1 by means of bolt connection, the slide rail 2 is provided with a slide block 3, the slide block 3 is slidingly connected with the slide rail 2, the top of the slide block 3 is connected with a slag receiving tray 4, and the bottom right side of the slag receiving tray 4 is Roller 5 is provided....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com