Improved high-pressure volumetric-method gas adsorption instrument coal sample tank

A coal sample tank and Favas technology, which is applied in the field of improved high-pressure capacity Favas adsorption instrument coal sample tank, can solve the problems of increased experimental electricity consumption, consumption of human and financial resources, error in experimental results, etc., and achieves simple structure and low cost. Inexpensive, temperature-stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

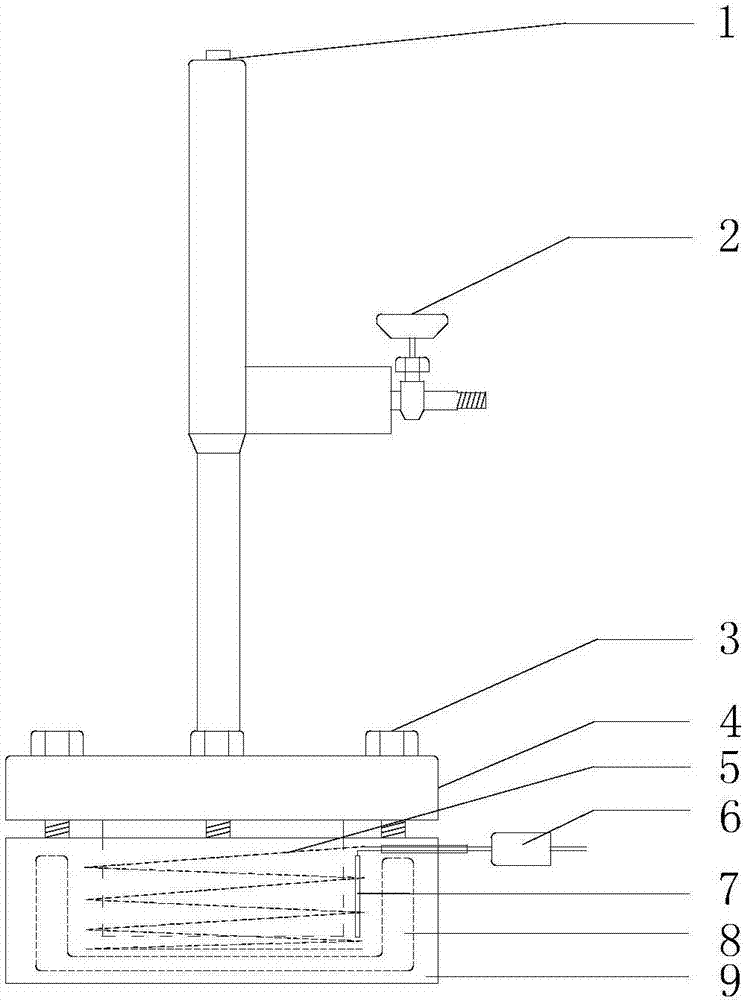

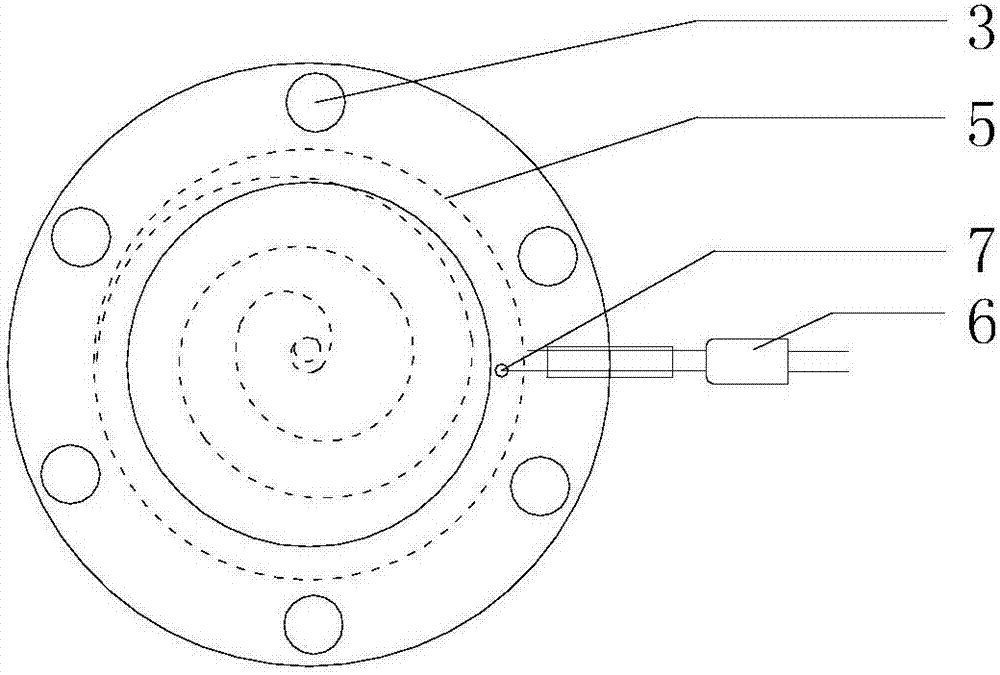

[0009] Embodiments of the present invention: an improved high-pressure capacity fagas adsorption instrument coal sample tank, comprising a tank body 9, the tank body 9 is a columnar structure with an open top, and a heat preservation tank 8 is provided in the side wall of the tank body 9. The thermal insulation tank 8 is filled with a thermal insulation material layer, and a heating resistance wire 5 and a thermistor 7 are arranged in the middle of the tank body 9, and the heating resistance wire 5 and the thermistor 7 are connected to the temperature control device 6; A coal sample tank upper cover 4 is provided on the top, and a data transmission hole 1 for a temperature probe and an air pressure control switch valve 2 are arranged on the coal sample tank upper cover 4; the coal sample tank upper cover 4 is fixed on the tank body 9 by fastening bolts 3 top.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com