Rotary Changer

A technology of rotating body and rotating shaft, applied in the direction of tool changing device, positioning device, electrode accessories, etc., can solve problems such as damage, deformation of gun body and welding torch components, and achieve the effect of avoiding deformation or damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

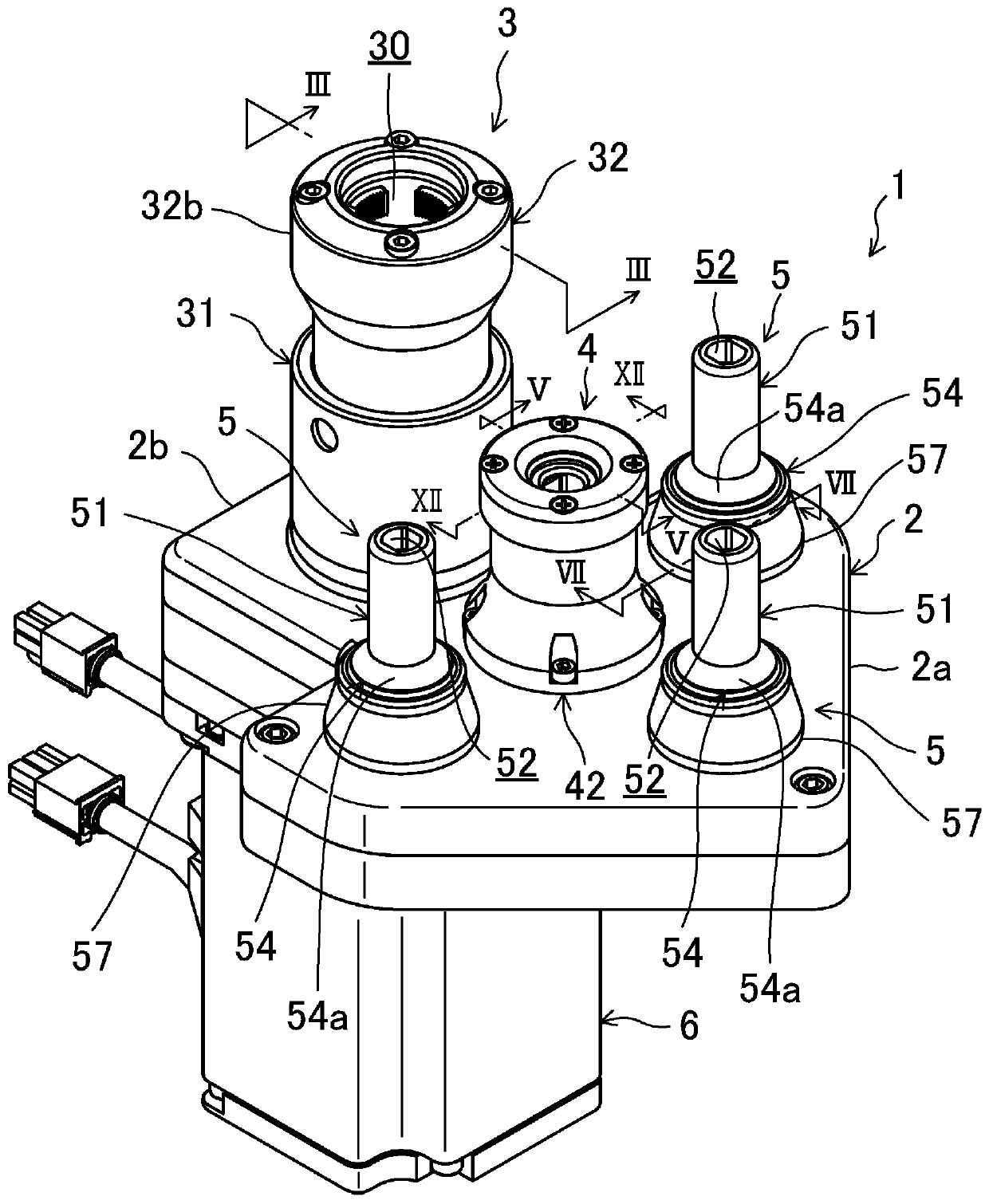

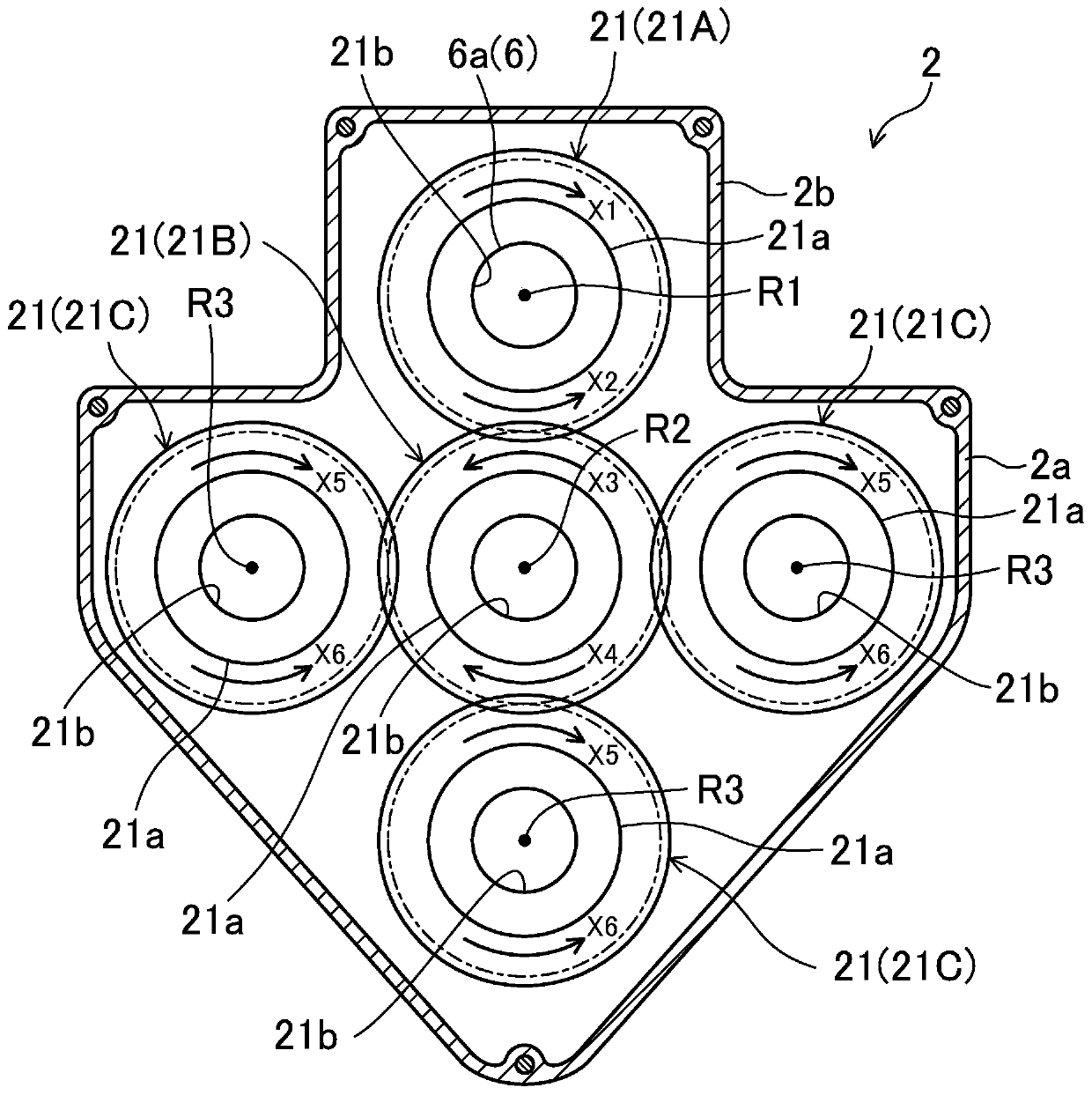

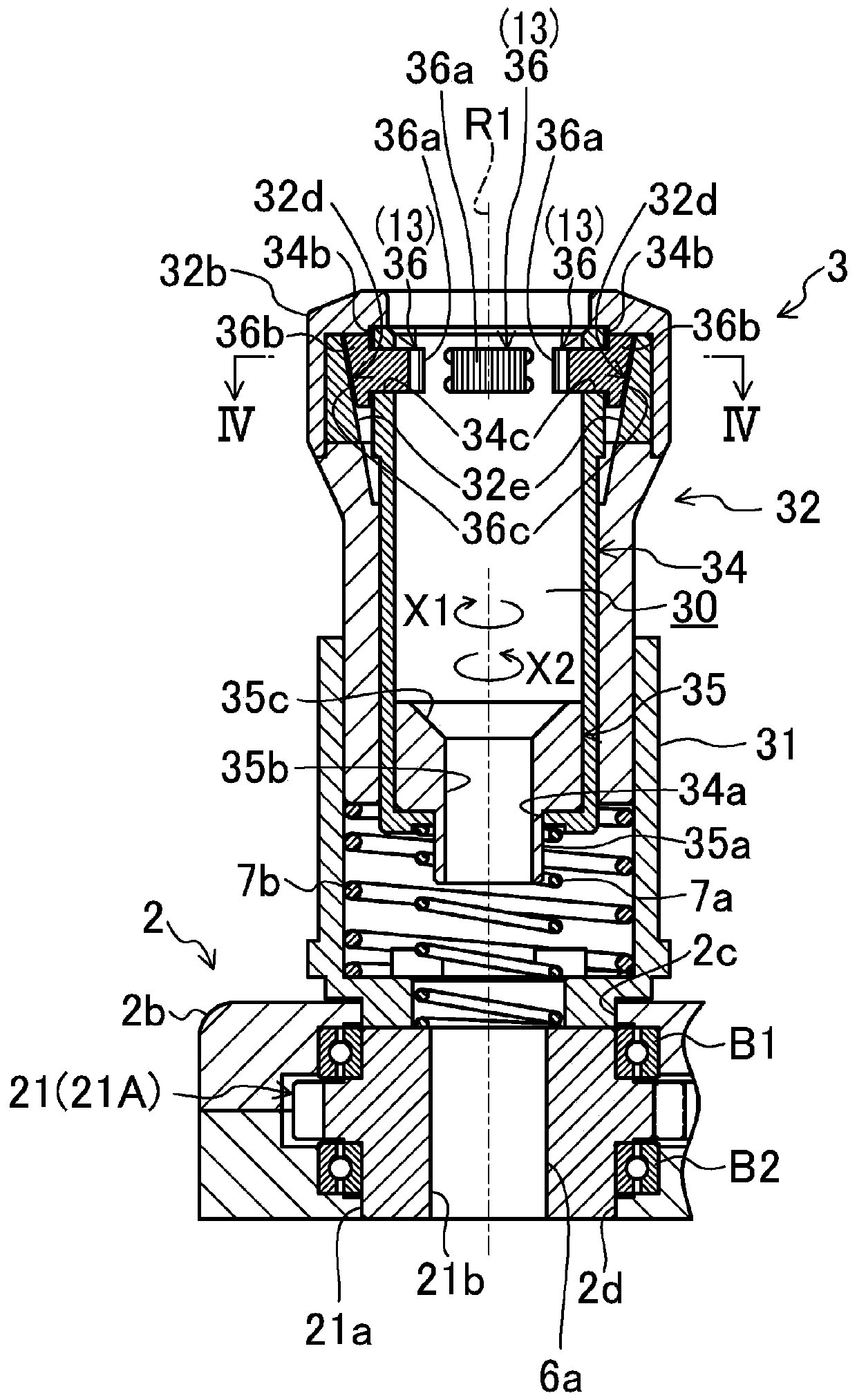

[0080] figure 1 The rotation exchange device 1 according to the first embodiment of the present invention is shown. The rotary replacement device 1 is used to automatically replace a metal nozzle 11 and a contact tip 12, which are torch components of a welding torch 10 used when welding steel plates or the like by arc welding (see Figure 8 to Figure 21 ).

[0081] The welding gun 10 has a cylindrical gun body 10a, and the cylindrical nozzle 11 is detachably connected to a distal end portion of the gun body 10a by screws.

[0082] The tip side of the nozzle 11 has a tapered shape whose diameter gradually decreases as it approaches the tip opening. On the other hand, on the outer peripheral surface of the base end side of the nozzle 11, a knurling extending in the circumferential direction is formed. The engaged portion 11a.

[0083] That is, the engaged portion 11a is configured such that a large number of tooth portions and tooth groove portions extending along the central...

no. 2 approach

[0205] Figure 22 to Figure 29 The removal unit 4 of the rotation replacement apparatus 1 which concerns on the 2nd Embodiment of this invention is shown. In the second embodiment, only a part of the structure of the disassembly unit 4 and the method of discarding the used contact tips 12 detached from the gun body 10a are different from those of the first embodiment, and other aspects are the same as the first embodiment. , so only the parts different from the first embodiment will be described in detail below.

[0206]The first concave groove 41e is not formed in the thick portion 41b of the first rotating body 41 of the second embodiment, as in the first embodiment.

[0207] In addition, the stopper member 41d is not fitted into the outer peripheral surface of the lower end of the first rotating body 41 as in the first embodiment.

[0208] Further, a contact portion 41f in the shape of a mortar is formed on the upper opening periphery of the through hole 41a of the first ...

no. 3 approach

[0249] Figure 30 to Figure 36 The removal unit 4 of the rotation replacement apparatus 1 which concerns on the 3rd Embodiment of this invention is shown. In the third embodiment, only a part of the structure of the disassembly unit 4 and the method of discarding the used contact tips 12 detached from the gun body 10a are different from those of the second embodiment, and the other aspects are the same as the second embodiment. , so only the parts different from the second embodiment will be described in detail below.

[0250] like Figure 30 and Figure 31 As shown, an annular wall portion 41g that bulges outward and extends upward is provided on the outer peripheral edge portion of the upper end of the thick wall portion 41b on the first rotating body 41 of the third embodiment. On the inner peripheral surface of the upper half of the , four recessed portions 41h which are recessed toward the radially outer side and extend up and down are formed at equal intervals around ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com