Processes for producing aliphatic polyester composition, molded object, and aliphatic polyester

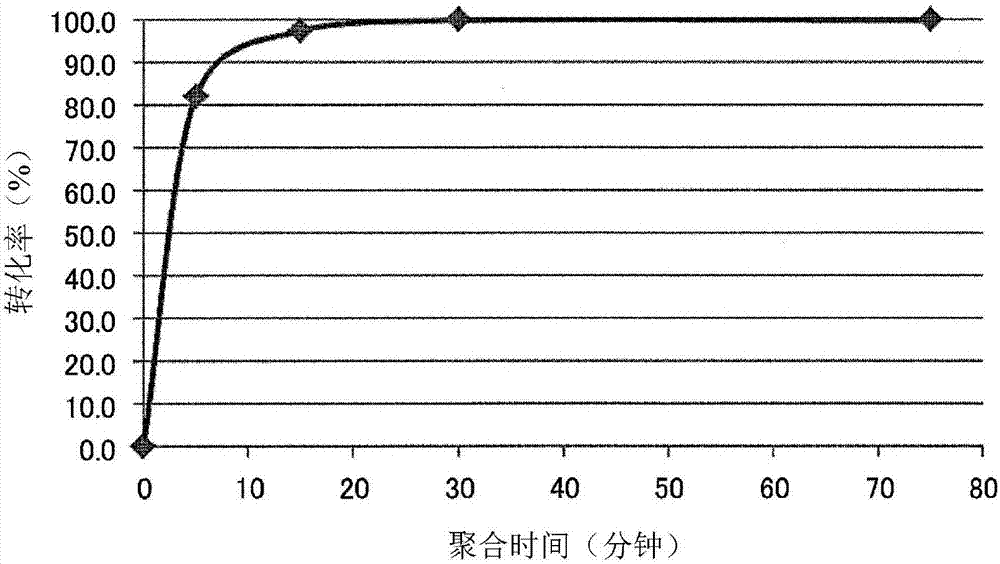

A technology of aliphatic polyester and its manufacturing method, applied in the direction of single-component polyester rayon, etc., can solve the problems of inability to manufacture aliphatic polyester composition stably and continuously, and achieve the effect of high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

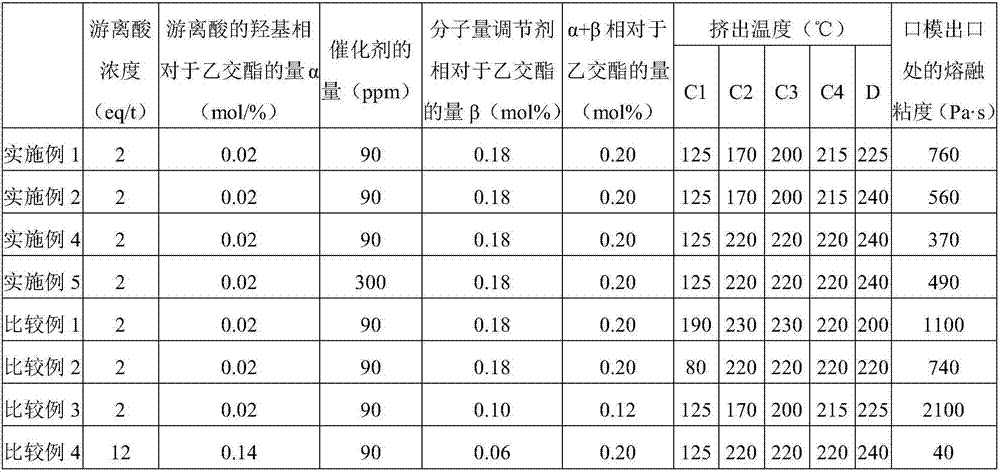

[0105] [Process 1]

[0106] In a drying room controlled to have a dew point of -40° C. or lower, 1.2 kg of glycolide (manufactured by Kureha Co., Ltd.) was placed in a beaker, and the beaker was heated to 100° C. to completely dissolve it. To this glycolide melt, 1.39 g of propylene glycol (manufactured by Junsei Chemical) (0.18 mol% relative to glycolide) and 108 mg of stannous chloride dihydrate (manufactured by Kanto Chemical Co., Ltd.) were added and stirred. After the mixture became completely homogeneous, it was further stirred for 5 minutes. This molten liquid was quickly transferred to an aluminum container, cooled to room temperature and solidified, and then pulverized to a size of about 10 mm. It should be noted that the free acid concentration in the glycolide used is 2eq / t.

[0107] Here, assuming that the free acid of glycolide is glycolic acid, the amount of hydroxyl groups derived from glycolic acid is 0.02 mol% with respect to glycolide. Glycolic acid also f...

Embodiment 2

[0123] As shown in Table 1, in addition to changing the temperature (°C) of the barrel and gear pump to C1 125 / C2 170 / C3 200 / C4215 / GP 240, the temperature is changed from the raw material supply port to the discharge port in four stages. A PGA molded product was obtained by the same method as in Example 1, except that the ground was raised. Table 2 shows the physical properties of the obtained PGA molded product. In addition, no fluctuations in discharge amount and resin pressure were observed in the operation for about 2 hours, and thus it was confirmed that the PGA composition and the molded article were produced stably and continuously.

Embodiment 3

[0125] The PGA molded article obtained in Example 2 was kept for 1 hour in an oven at 170°C blown with dry air having a dew point of -40°C. Table 2 shows the physical properties of the obtained PGA molded product. As shown in Table 2, it was confirmed that the concentration of unreacted glycolide in the obtained PGA molded product (hereinafter referred to as the residual GL concentration) decreased from 1.1% by weight to 0.1% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com