Etching solution for copper or copper alloy, etching method, and method for managing reproduction of etching solution

A management method and technology of etching solution, which is applied in the field of etching solution, can solve problems such as difficulties and impracticalities, and achieve the effects of suppressing side erosion and small changes in etching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0068] [Preparation of etching solution]

[0069] In 270 grams (100 grams in the form of anhydrous) commercially available 40o Bomei ferric (III) chloride aqueous solution (concentration 37% by mass), 25 grams (20 grams in the form of anhydrous) copper chloride (II) ) dihydrate, 14 g (10 g in anhydrous form) oxalic acid dihydrate, add 1 kg of water to prepare 10 mass % iron (III) chloride, 2 mass % copper chloride, 1 Mass % oxalic acid etchant.

[0070] [Etching and Regeneration]

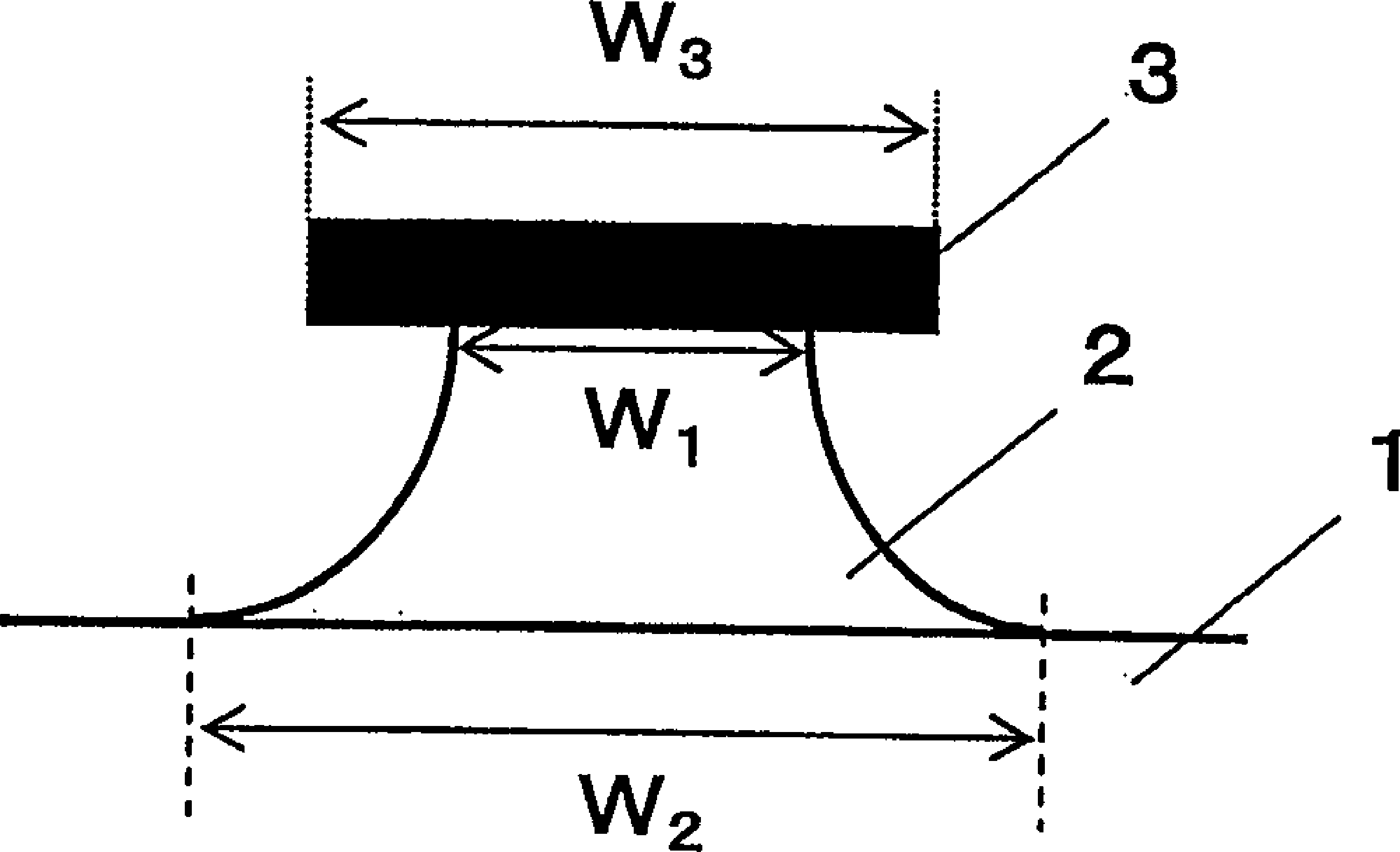

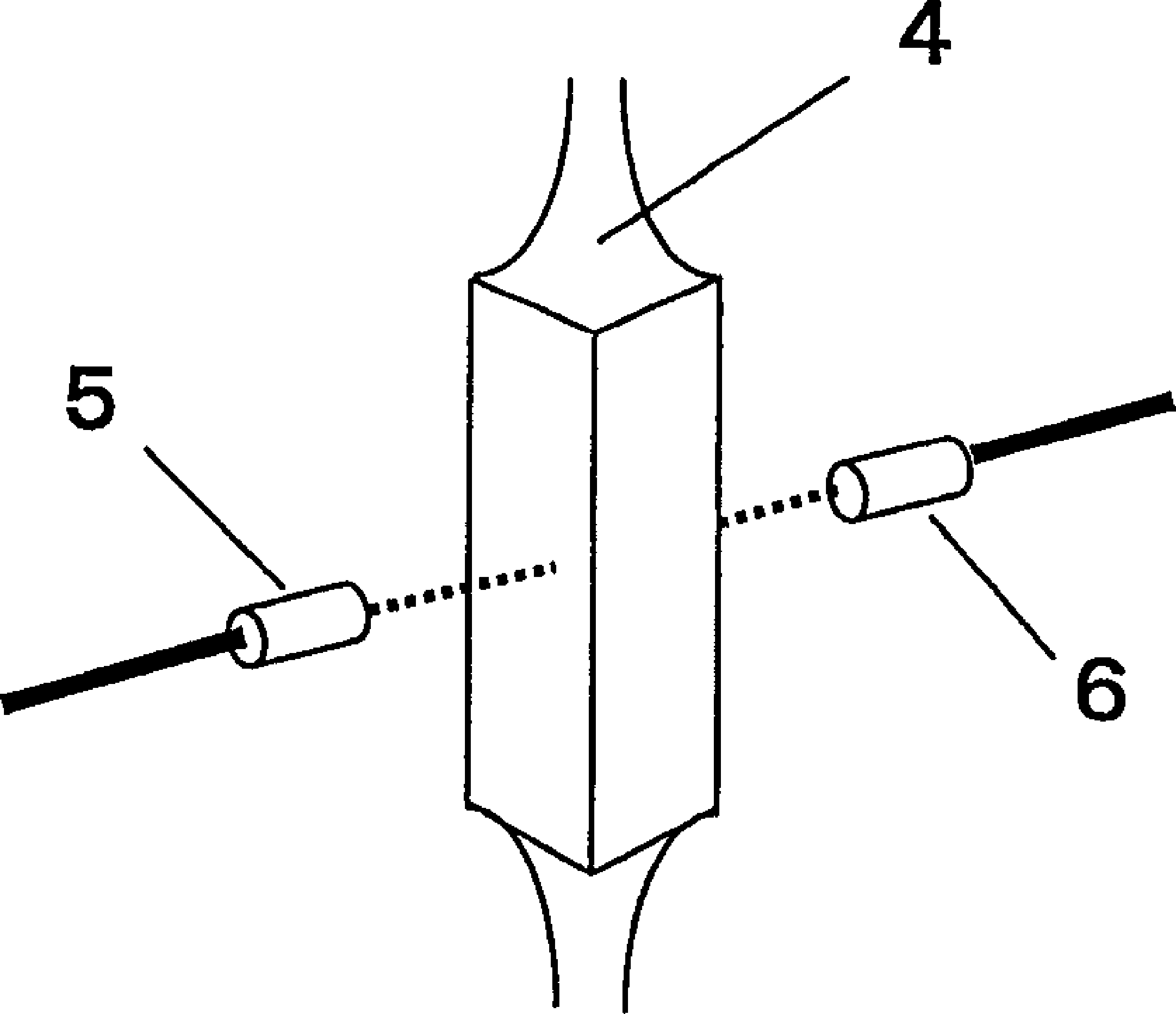

[0071] On a glass epoxy substrate with a rolled copper foil with a thickness of 9 μm on the surface, the lines were formed using a positive photoresist (w 3 ) / gap widths are each 25 μm / 25 μm of the resist pattern. The etching was performed by spraying the above-mentioned etching solution adjusted to 20° C. toward the above-mentioned substrate under the conditions of a liquid supply pressure to the nozzle of 150 kPa and an injection volume of 1320 mL / min using a full-cone nozzle with a diameter of...

Embodiment 2~9、 comparative example 1~13)

[0075] In the same manner as in Example 1, etching solutions containing the respective composition concentrations shown in Tables 1 to 3 were prepared, and on the substrate on which the same resist pattern as in Example 1 had been formed, the same regeneration and etching treatment were performed, and the same Evaluation.

[0076] [Table 1]

[0077]

[0078] [Table 2]

[0079]

[0080] [table 3]

[0081]

[0082] As can be seen from Table 1, the etching solution of the present invention has less side etching and less change in etching rate even when regeneration is performed. In particular, it was found that an etching solution using oxalic acid as a compound that forms an insoluble salt with copper is an etching solution with very few side etchings.

[0083] On the other hand, as in Comparative Examples 1, 2, and 7, in the etching solution to which the compound that forms an insoluble salt with copper was not added, almost no suppression of side etching was observ...

Embodiment 10)

[0086] [Preparation of etching solution]

[0087] In 216 grams (100 grams in the form of anhydrous) commercially available 40o Bomei ferric (III) chloride aqueous solution (concentration 37% by mass), 25 grams (20 grams in the form of anhydrous) copper (II) chloride ) dihydrate, 7 grams (5 grams in the form of anhydrous) oxalic acid dihydrate, add 1 kg of water to prepare iron (III) chloride containing 8 mass %, 2 mass % copper chloride, 0.5 mass % oxalic acid etching solution.

[0088] [etching]

[0089] On a glass epoxy resin substrate with a rolled copper foil with a thickness of 9 μm on the surface, a full cone nozzle with a diameter of 20 cm of the spray surface was used, and the liquid supply pressure to the nozzle was 150 kPa and the spray rate was 1000 mL / min. The etching was performed by spraying the above-mentioned etching solution adjusted to 30°C toward the above-mentioned base material.

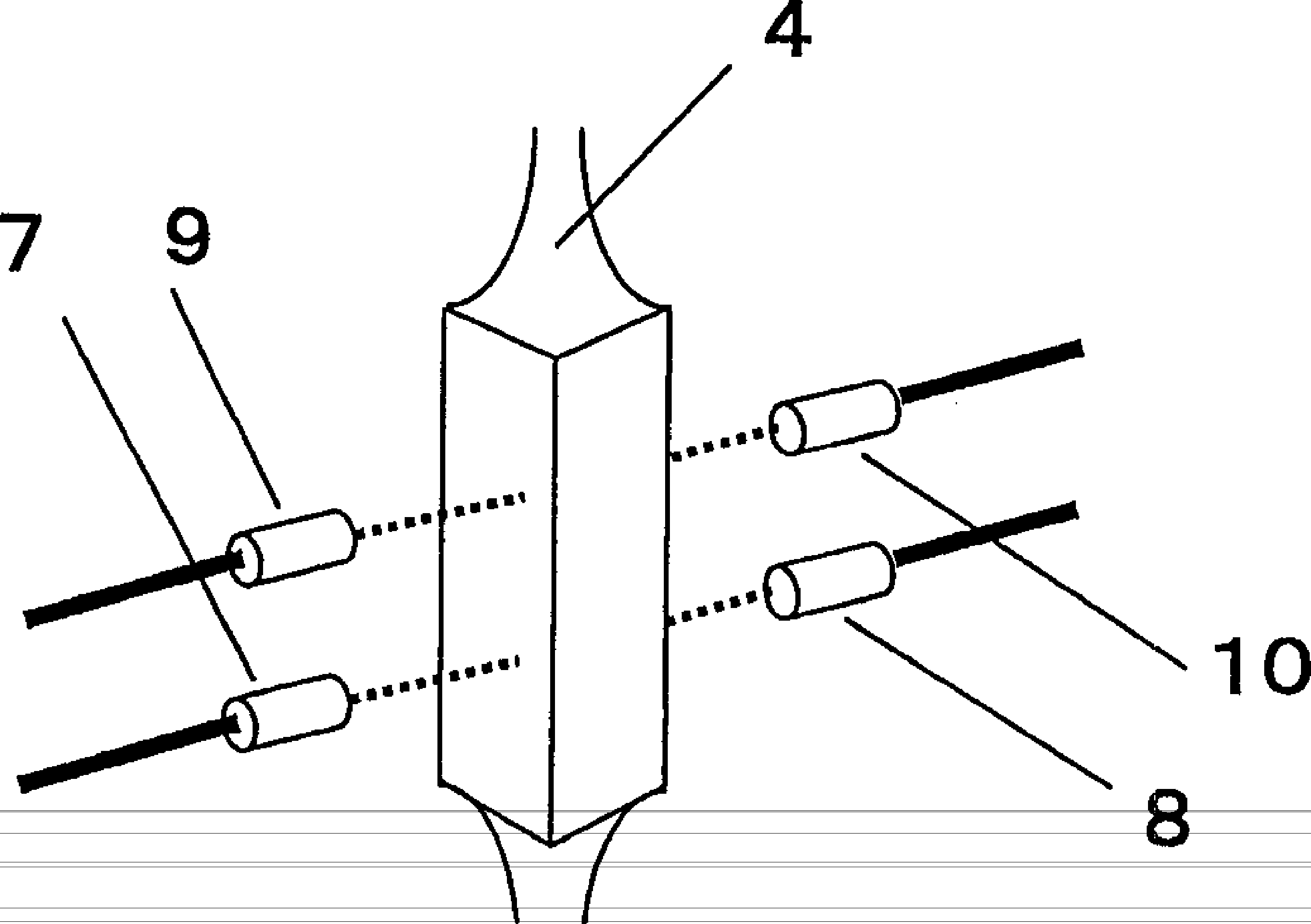

[0090] [Numerical measurement for regeneration management]

[0091] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com