Photosensitive resin composition for glass processing and glass processing method

A technology of photosensitive resin and composition, which is applied in the field of photosensitive resin composition for glass processing and glass processing, can solve the problems of poor yield, reduced strength, cracks, etc., and achieve the purpose of suppressing side erosion, suppressing liquid dripping, Excellent resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0176]

[0177] The photosensitive resin composition for glass processing according to the present invention can be prepared by merely mixing and stirring the above-mentioned components by a usual method, and if necessary, disperse them using a dissolver, a homogenizer, a three-roll mill, etc. machine for dispersion and mixing. In addition, after mixing, filtration may be further performed with a mesh, a membrane filter, or the like.

[0178] "Glass Processing Method"

[0179] The first glass processing method according to the present invention includes a resin layer forming step of forming a resin layer containing the first photosensitive resin composition for glass processing according to the present invention on a glass substrate, and an exposing step of selectively exposing the resin layer. , a developing step of developing the exposed resin layer to form a resin pattern, an etching step of etching the glass substrate using the resin pattern as a mask, and a peeling ste...

Embodiment 17~20

[0261] Formation of resin layer using dry film

[0262] After coating the positive-type photosensitive resin composition of Example 1, 4 or 5 or the negative-type photosensitive resin composition of Example 12 on a support film comprising a PET film with an applicator, the coating was carried out at 120° C. The film was heated and dried for 10 minutes to obtain a dry film including a resin layer with a film thickness of 60 μm. The support film was peeled off from the dry film, and the newly exposed surface of the dry film was attached to a glass substrate (manufactured by Corning, Eagle-XG, thickness 0.7mm), and bonded to the glass substrate by thermal compression bonding using a heated roller. Cover with dry film. At this time, the surface temperature of the roll was heated to 80° C., the roll pressure was set to 0.1 MPa (G), and the moving speed was set to 0.1 m / min. In addition, the glass substrate was preheated to 60°C.

[0263] Developability, resolution, etching resis...

Embodiment 21~55、 comparative example 8~21

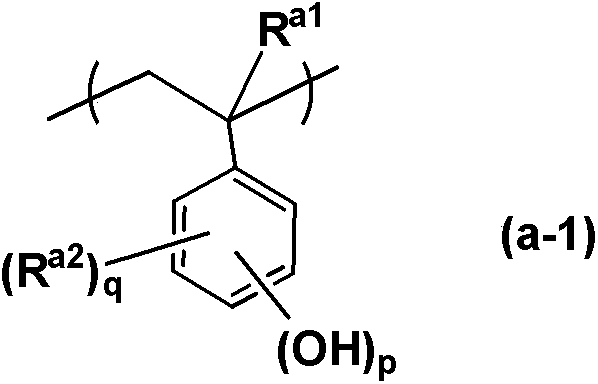

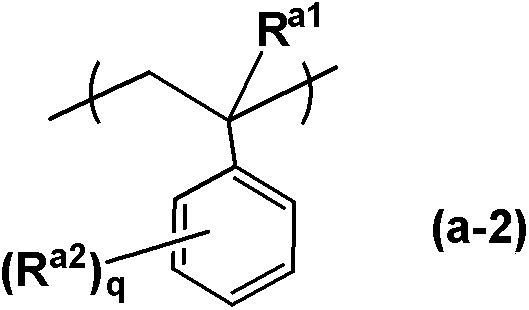

[0268] According to the formulations (units are parts by mass) recorded in Tables 9 to 13, mix resins with hydroxyl groups, fillers, rheology modifiers, compounds containing quinone diazide groups, polyvinyl alkyl ethers and solvents, and prepare examples 21-42 and the positive-type photosensitive resin compositions of Comparative Examples 8-15.

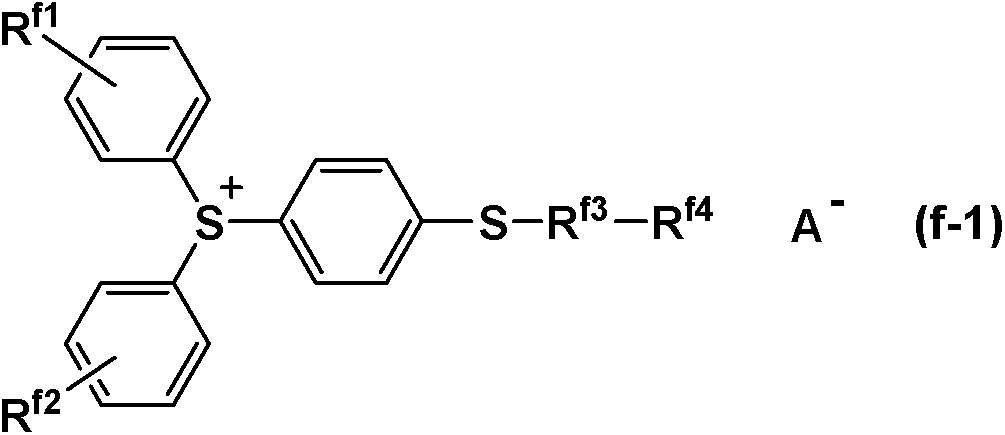

[0269] In addition, according to the formulations (units are parts by mass) recorded in Tables 14 to 16, resins with hydroxyl groups, fillers, rheology modifiers, crosslinking agents, acid generators, polyvinyl alkyl ethers and solvents were mixed to prepare and implement Negative photosensitive resin compositions of Examples 43-55 and Comparative Examples 16-21.

[0270] Details of each component in Tables 9 to 16 are as follows.

[0271] Resins A to I having hydroxyl groups: Same as above

[0272] Packing A~C and E: Same as above

[0273] Filler D': silica fine particles (manufactured by Japan Aerosil Corporation, AEROSIL (regis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com