Composition for forming resin thin film for hydrofluoric acid etching and resin thin film for hydrofluoric acid etching

A resin film, hydrofluoric acid technology, applied in surface etching compositions, chemical instruments and methods, photosensitive materials for opto-mechanical equipment, etc. The effect of excellent, excellent hydrofluoric acid barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

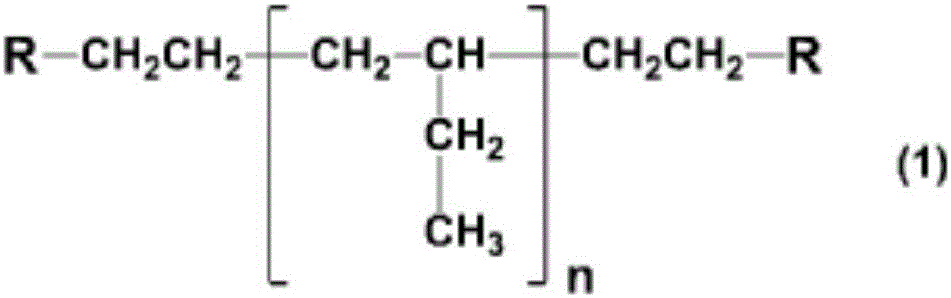

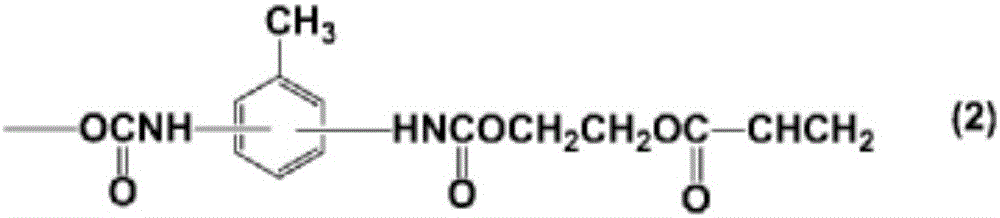

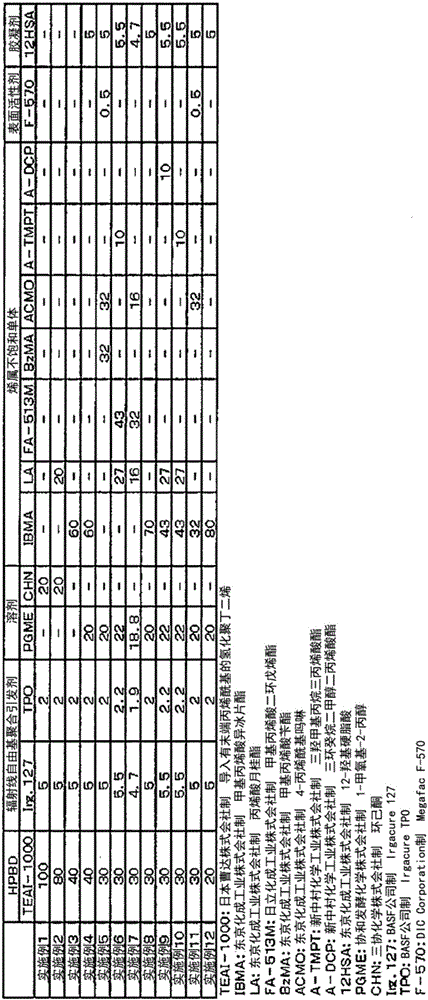

[0194] As a hydrogenated polybutadiene compound (HPBD) having a (meth)acryloyl group, TEAI-1000 (weight average molecular weight: 5500) manufactured by Nippon Soda Co., Ltd. was used, and the components were mixed in the mass ratio described in Table 1, Thus a composition is prepared.

[0195] [Table 1]

[0196]

Embodiment 5

[0198] In Example 5, except that UV-2750B (urethane acrylate resin manufactured by Nippon Synthetic Chemical Industry Co., Ltd.) was used instead of TEAI-1000, the components were mixed at the same mass ratio to prepare a composition .

[0199] (2) Preparation of cured film and evaluation of hydrofluoric acid resistance

Embodiment 13~24、 comparative example 2

[0201] The compositions prepared in Examples 1 to 12 and Comparative Example 1 were coated on surfaces with a thermally oxidized film (SiO 2 On a silicon substrate (film thickness: 300 nm), the coating film was baked on a hot plate at 110° C. for 2 minutes, and cooled at room temperature for 2 minutes to form a resin film on the substrate.

[0202] Next, each resin film was subjected to UV exposure (55mW / cm 2 , 999mJ) was baked and cured at 150° C. for 5 minutes using a hot plate to form a cured film. In addition, the film thickness is 30 micrometers - 50 micrometers.

[0203] Next, each substrate with a cured film was immersed in a mixed acid aqueous solution (hereinafter also referred to as etching solution) containing 9% by mass of hydrofluoric acid and 8% by mass of sulfuric acid at 25° C., and was carried out for 60 minutes while circulating the etching solution. minute etching process. Thereafter, the substrate was washed with water, and then the cured film was peeled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com