A kind of nano silkworm chrysalis protein powder and preparation method thereof

A silkworm chrysalis protein powder, nanotechnology, applied in the field of silkworm chrysalis protein powder, can solve the problems of protein loss, high protein residue, deterioration, etc., to avoid the loss of nutrients, excellent nutritional value, and solve the effect of color and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

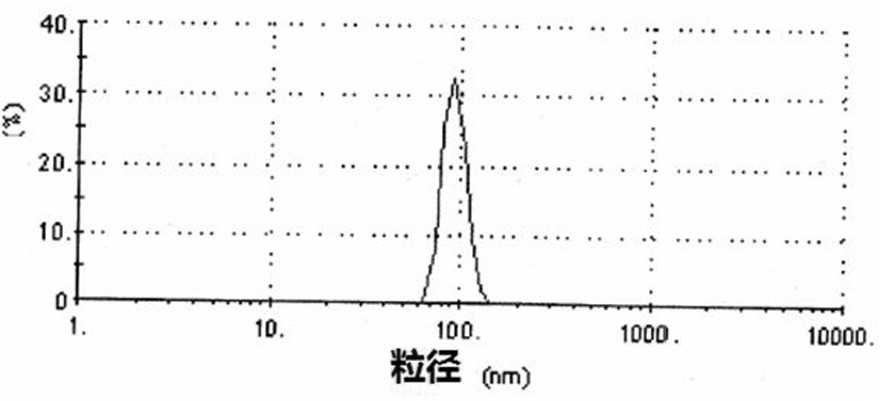

Image

Examples

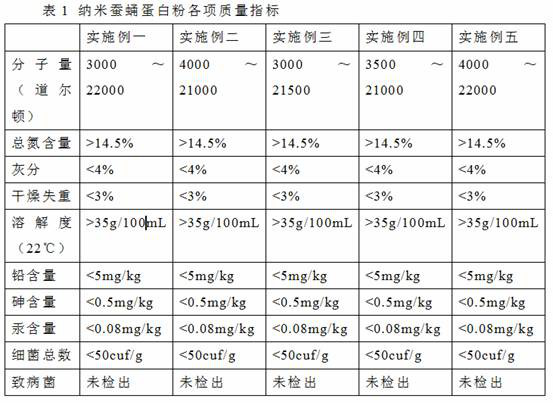

Embodiment 1

[0043] A preparation method of nano silkworm chrysalis protein powder, comprising the following steps:

[0044](1) The degreased pupae were first washed with tap water and then washed with pure water, then added to water, then subjected to wall breaking treatment, and then ultrasonic treatment to obtain the treatment solution; the speed of wall breaking treatment was 50000rpm, and the time was 35 minutes; the defatted pupae and water The mass ratio is 1:25; the power of ultrasonic treatment is 700W, and the frequency is 40KHz;

[0045] (2) Add adsorbent activated carbon to the treatment liquid, and conduct adsorption treatment at 80°C; then press filter to obtain the filtrate; the amount of activated carbon added is 2% of the mass of the treatment liquid;

[0046] (3) Add papain to the filtrate, and carry out enzymolysis under vibration conditions to obtain an enzymolysis solution; the dosage of papain is 2500 activity units / mL filtrate, the enzymolysis temperature is 48°C, th...

Embodiment 2

[0052] A preparation method of nano silkworm chrysalis protein powder, comprising the following steps:

[0053] (1) The degreased pupae were first washed with tap water and then washed with pure water, then added to water, then subjected to wall breaking treatment, and then ultrasonic treatment to obtain the treatment solution; the speed of wall breaking treatment was 45000rpm, and the time was 30 minutes; the defatted pupae and water The mass ratio is 1:30; the power of ultrasonic treatment is 500W, and the frequency is 50KHz;

[0054] (2) Add adsorbent activated carbon to the treatment liquid, and conduct adsorption treatment at 80°C; then press filter to obtain the filtrate; the amount of activated carbon added is 2% of the mass of the treatment liquid;

[0055] (3) Add papain to the filtrate, and carry out enzymolysis under vibration conditions to obtain the enzymolysis solution; the dosage of papain is 3000 activity units / mL filtrate, the enzymolysis temperature is 50°C, ...

Embodiment 3

[0059] A preparation method of nano silkworm chrysalis protein powder, comprising the following steps:

[0060] (1) The degreased pupae were first washed with tap water and then washed with pure water, then added to water, then subjected to wall breaking treatment, and then ultrasonic treatment to obtain the treatment liquid; the speed of wall breaking treatment was 50000rpm, and the time was 40 minutes; the defatted pupae and water The mass ratio is 1:30; the power of ultrasonic treatment is 800W, and the frequency is 30KHz;

[0061] (2) Add adsorbent activated carbon to the treatment liquid, and conduct adsorption treatment at 85°C; then press filter to obtain the filtrate; the amount of activated carbon added is 3% of the mass of the treatment liquid;

[0062] (3) Add papain to the filtrate, and carry out enzymolysis under vibration conditions to obtain the enzymolysis solution; the dosage of papain is 3000 activity units / mL filtrate, the enzymolysis temperature is 50°C, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com