Cleaning dust return system for floor washing machine

A washing machine and cleaning brush technology, applied in the direction of cleaning carpets, cleaning floors, manual sweeping machines, etc., can solve the problems of large power consumption, large energy proportion, flying dust, etc., to achieve reduced power consumption, convenient operation, and manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

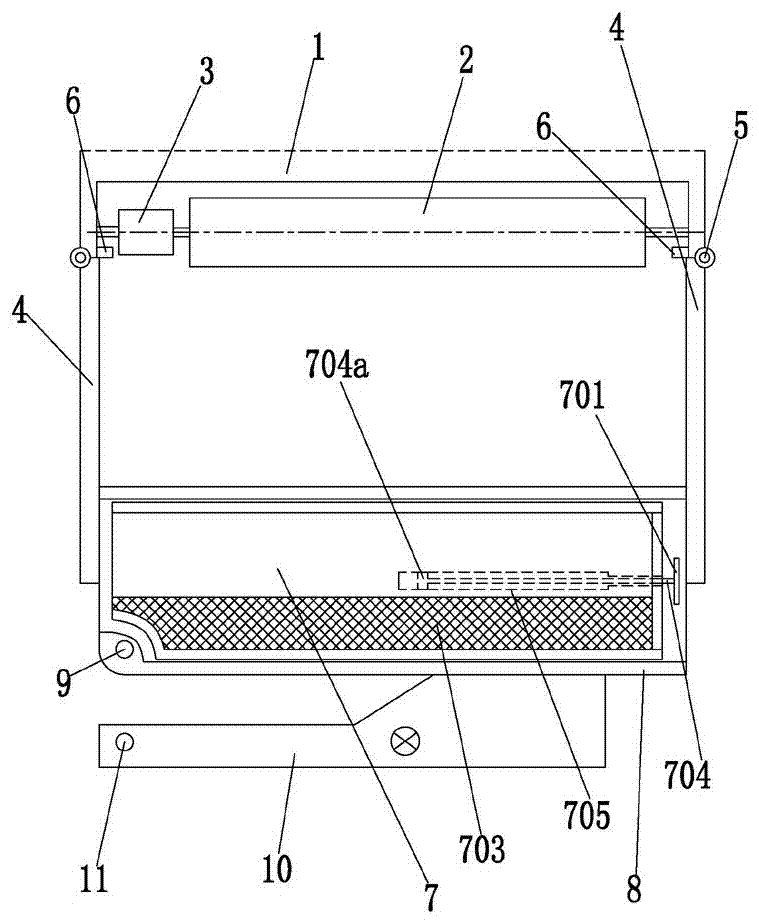

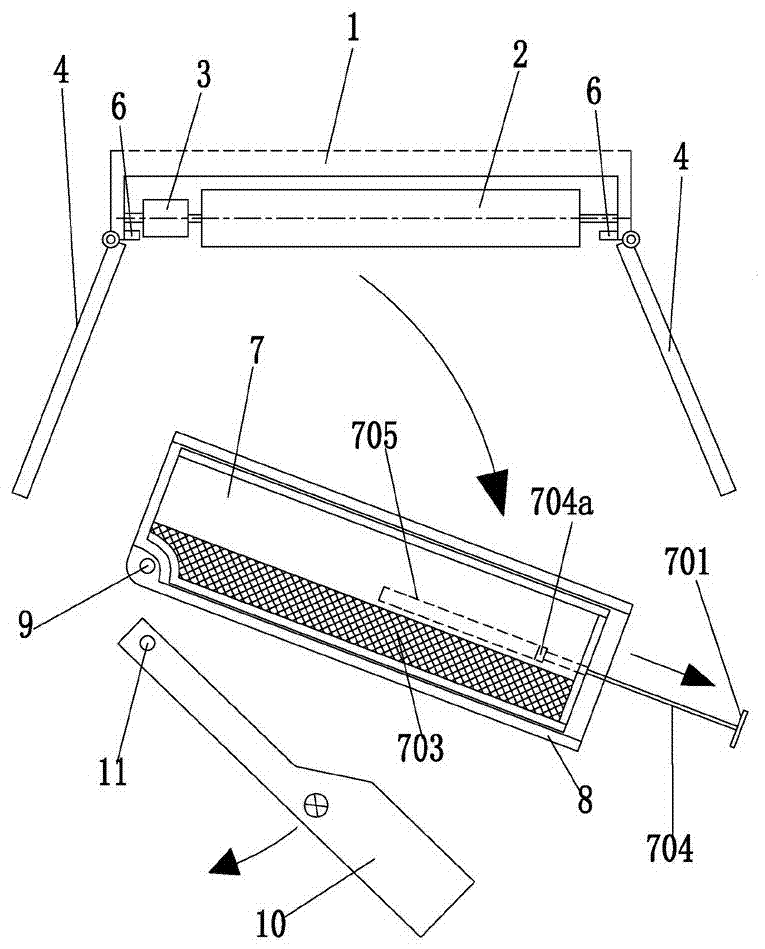

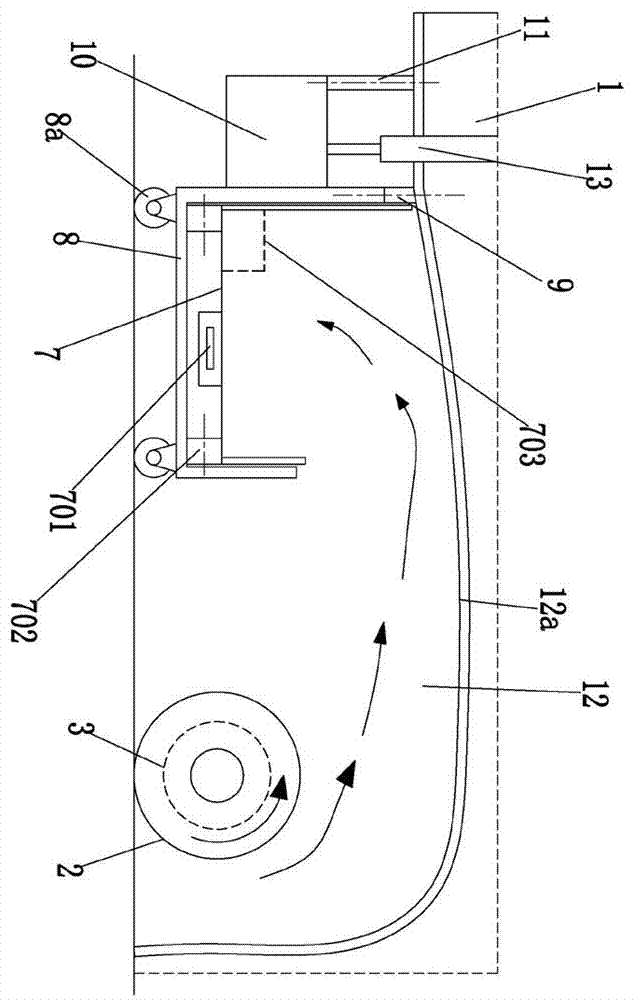

[0019] Such as Figure 1-3 As shown, a cleaning and dust return system for a floor washing machine includes a frame 1, a cleaning brush 2, a brush driving mechanism 3 for driving the cleaning brush 2 to rotate at high speed, and a dust return bin with a closed structure The chamber 12 also includes two sets of sealing assemblies that respectively seal the two sides of the dust return chamber 12, and also includes a movable base 8, a first rotating shaft 9, and is detachably installed on the movable base 8 for collecting dust, The drawable recovery bin 7 with an open upper end also includes a movable limit seat 10 , a second rotating shaft 11 , and a locking assembly 13 .

[0020] The sealing assembly includes a sealing door 4 , a door hinge shaft 5 , and a door lock 6 for locking the position of the sealing door 4 . One end of the sealing door 4 is rotatably mounted on the frame 1 through the door hinge shaft 5 .

[0021] The cleaning brush 2 is located in the dust return cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com