Production method of novel plastic composite pipe

A production method and technology for composite pipes, which are applied to tubular articles, applications, household appliances, etc., can solve the problems of easy slippage of inner pipes, easy damage and slippage of composite pipes, and achieve good thermal insulation effect, reduce production costs, and prevent explosions. tube effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Now the present invention is further described in conjunction with description of drawings and embodiments:

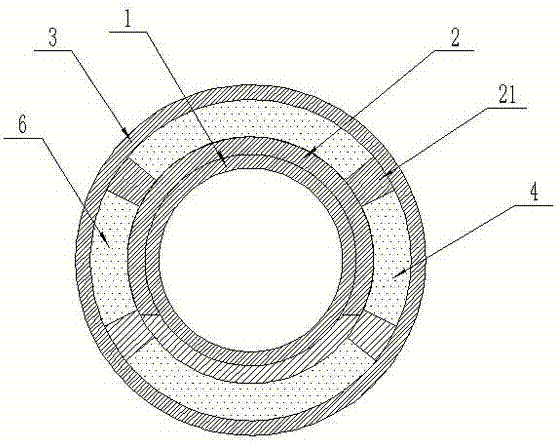

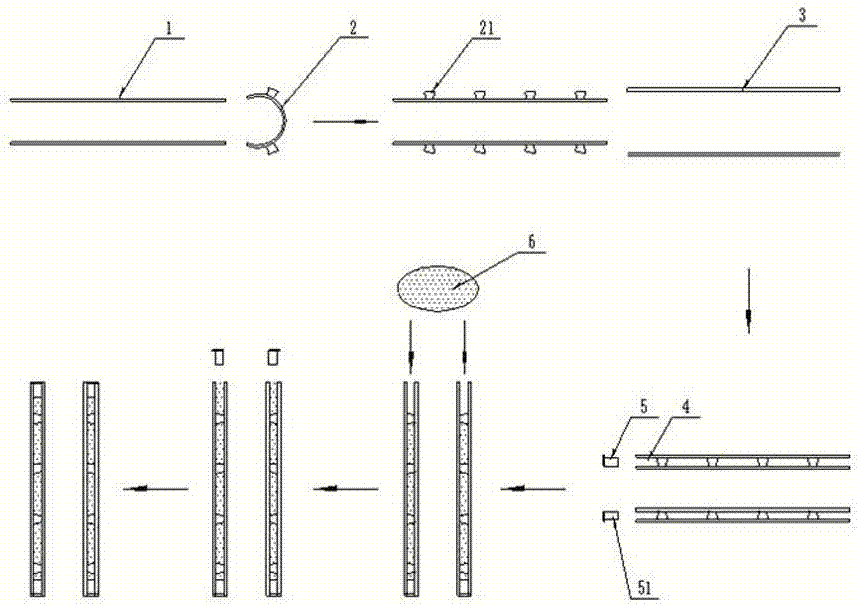

[0021] refer to figure 1 , figure 2 , a production method of a novel plastic composite pipe, comprising the following steps:

[0022] (1) In the production of the inner tube 1, a plurality of positioning clamps 2 are clamped on the outer surface of the inner tube 1 by an extrusion device;

[0023] (2) Driven by the traction device, fit the outer tube 3 on the outer surface of the inner tube 1, the protrusion 21 on the positioning clip 2 is stuck on the inner wall of the outer tube 3, and the inner tube 3 An annular passage 4 is formed between the pipe 1 and the outer pipe 3 to obtain a composite pipe with openings at both ends;

[0024] (3) Apply hot melt adhesive to the annular channel 4 at one end of the composite pipe described in step (2), and use an extrusion device to clamp the plastic cover 5 into one end of the composite pipe to close;

[0025] (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com