Downhole cyclone desander

A swirl de-sanding and helical blade technology, applied in the fields of production fluid, wellbore/well components, earth-moving drilling, etc., can solve the problems of sediment inhalation and pump sticking, and achieve the effect of preventing pump sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] In order to facilitate the understanding of those skilled in the art, the present invention will be described in detail below in conjunction with the accompanying drawings.

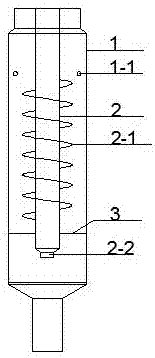

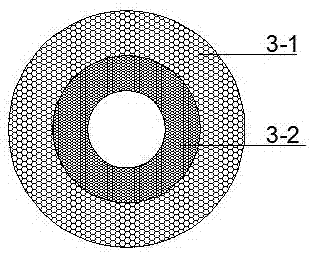

[0008] Such as figure 1 A downhole cyclone desander shown specifically includes an outer pipe 1 , an inner pipe 2 and a filter screen 3 . The outer tube is provided with an oil inlet hole 1-1, the outer wall of the inner tube is provided with a spiral blade 2-1, and the lower part of the inner tube is a reduced-diameter oil suction port 2-2, such as figure 2 As shown, the outer ring of the filter screen is a coarse mesh 3-1, and the inner ring of the filter screen is a fine mesh 3-2. When swirling, the larger particles of sand stick to the inner wall of the outer pipe on the outer layer, the smaller particles of sand are in the middle, and the oil is attached to the outer wall of the inner pipe to rotate. Different pore sizes of the filter screen can block the sand of different particle sizes, ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com