A servo loading demonstration system

A demonstration system and steering gear technology, applied in the direction of simulators, machine/structural component testing, measuring devices, etc., can solve the problems of complex steering gear demonstration system components, difficulties in manufacturing and maintenance, etc., to facilitate manufacturing and post-maintenance, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited by the examples.

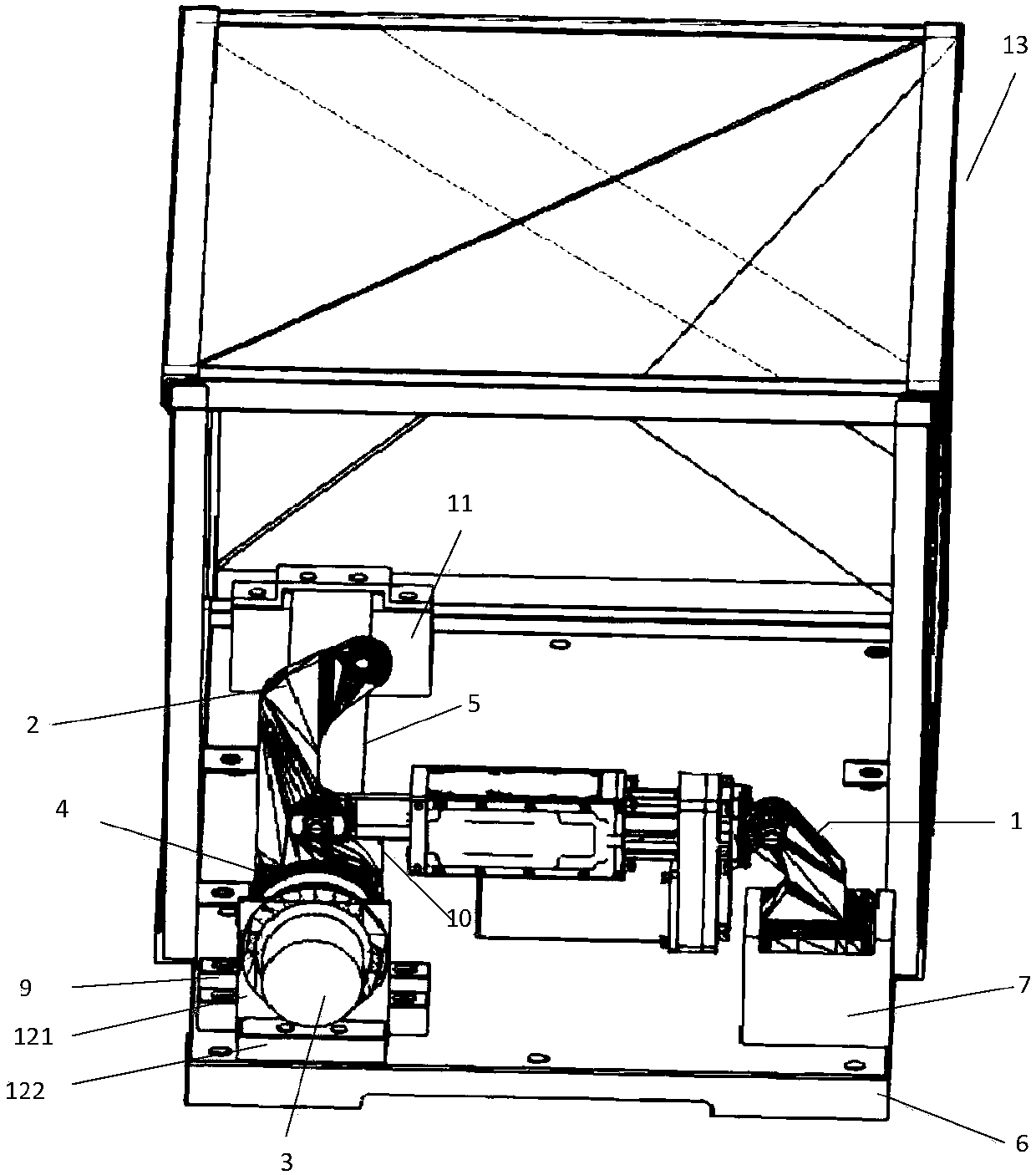

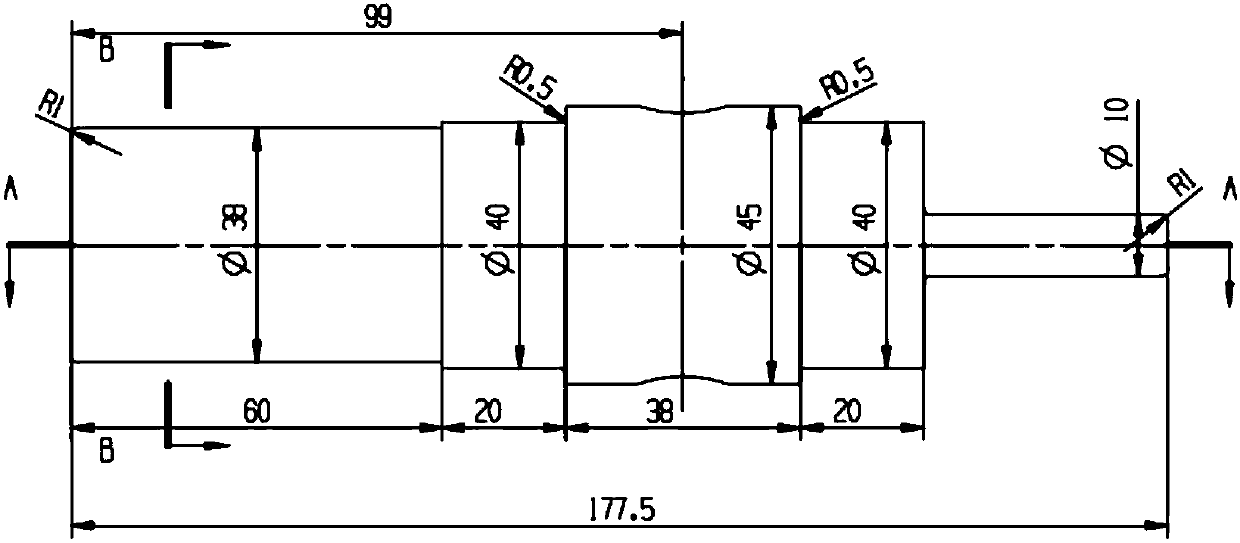

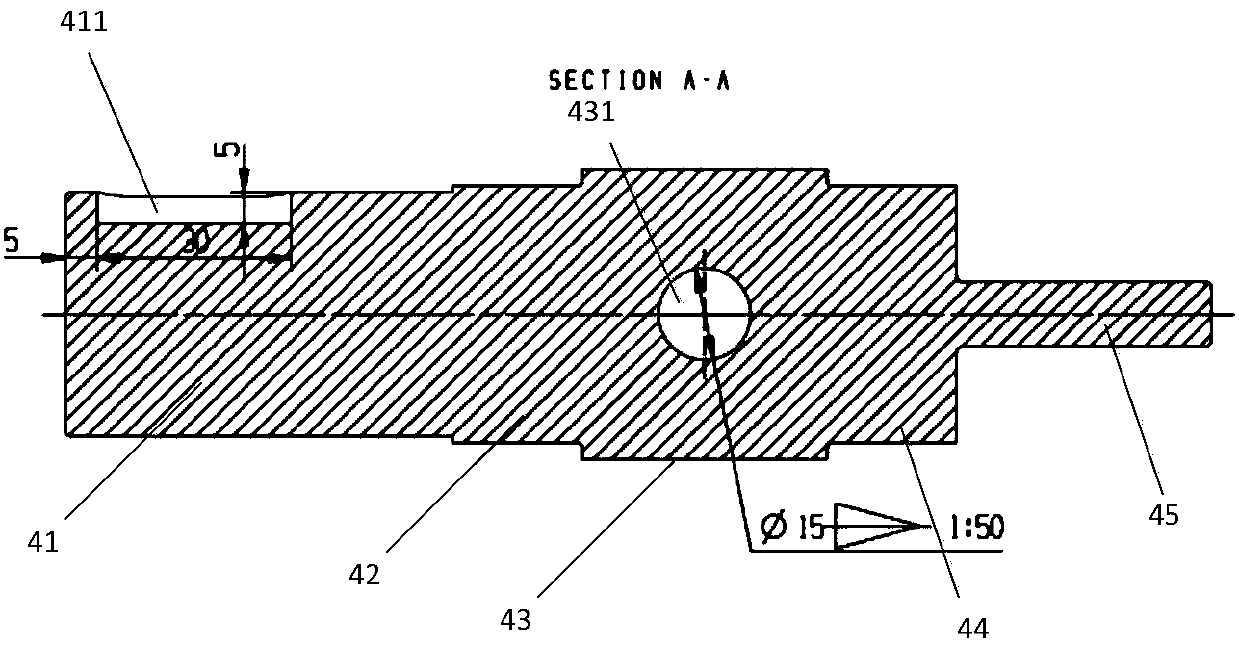

[0063] A steering gear loading demonstration system. The rocker arm converts the output axial force of the steering gear into a torque around the rotating shaft. After the torque is transmitted by the stressed rotating shaft, it acts on the spring steel sheet connected to the base. The torsion of the spring steel sheet form manifested. At the same time, an MCJD485B angle sensor is placed at the other end of the rotating shaft to measure the angle of the rotating shaft. After subtracting the calculated angle of torsional deformation of the rotating shaft, the material properties of the steel sheet can be used to calculate the final steering gear through the reducer, ball screw pair and The output torque after the rocker arm. The rocker arm is a rod with multiple pin holes that can change the distance of the force arm; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com