Machining process of PCB

A PCB board and processing technology technology, applied in the field of PCB board processing technology, can solve the problems of single-sided opening of solder mask holes, contaminated pads, and rising processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A PCB board processing technology, comprising the following process steps,

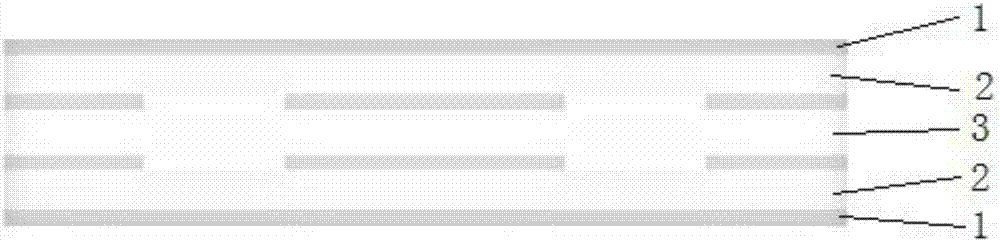

[0028] 1) Lamination is composed of circuit board 1, core board dielectric layer 2, circuit board 1, insulating layer 3, circuit board 1, core board dielectric layer 2 and circuit board 1 to form a PCB board, and the operating parameter is vacuum state The lamination pressure is controlled at 320psi, the circuit board 1 is raised from room temperature to 185°C, the heating rate is controlled at 2.5°C / min in the range of 100°C-170°C, the high temperature is maintained at 185°C for 60min, and then cooled to room temperature , the cooling rate is less than 3°C / min;

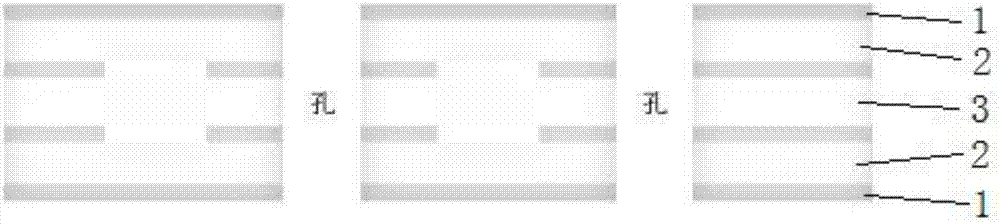

[0029] 2) Drilling, drilling in the vertical direction of the PCB board;

[0030] 3) Immerse copper to make the hole wall of the drilled PCB board conductive and form a metallized through hole. The copper thickness obtained by immersion copper plating is 5 μm;

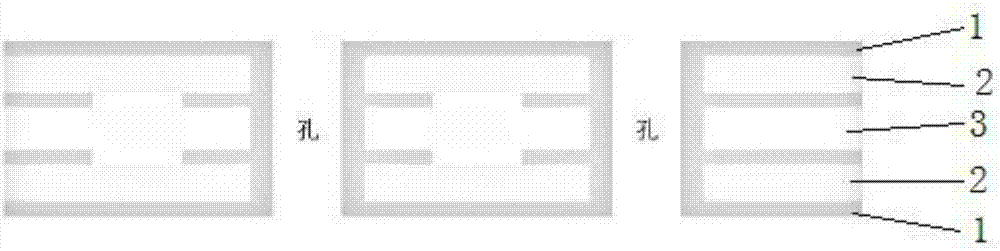

[0031] 4) Solder resist plugging holes, through the solder resist ink 4...

Embodiment 2

[0036] A PCB board processing technology, comprising the following process steps,

[0037] 1) Lamination is composed of circuit board 1, core board dielectric layer 2, circuit board 1, insulating layer 3, circuit board 1, core board dielectric layer 2 and circuit board 1 to form a PCB board, and the operating parameter is vacuum state The lamination pressure is controlled at 380psi, the circuit board 1 is raised from room temperature to 175°C, the heating rate is controlled at 3.5°C / min in the range of 100°C-170°C, the high temperature is maintained at 175°C for 70min, and then cooled to room temperature , the cooling rate is less than 3°C / min;

[0038] 2) Drilling, drilling in the vertical direction of the PCB board;

[0039] 3) Immerse copper to make the hole wall of the drilled PCB board conductive and form a metallized through hole. The copper thickness obtained by immersion copper plating is 15 μm;

[0040] 4) Solder resist plugging holes, through the solder resist ink ...

Embodiment 3

[0045] A PCB board processing technology, comprising the following process steps,

[0046] 1) Lamination is composed of circuit board 1, core board dielectric layer 2, circuit board 1, insulating layer 3, circuit board 1, core board dielectric layer 2 and circuit board 1 to form a PCB board, and the operating parameter is vacuum state The lamination pressure is controlled at 350psi, and the circuit board 1 is raised from room temperature to 180°C, and the heating rate is controlled at 3°C / min in the range of 100°C-170°C, and the high temperature is maintained at 180°C for 65min, and then cooled to room temperature , the cooling rate is less than 3°C / min;

[0047] 2) Drilling, drilling in the vertical direction of the PCB board;

[0048] 3) Immerse copper to make the hole wall of the drilled PCB board conductive and form metallized through holes. The thickness of copper obtained by immersion copper plating is 10 μm;

[0049] 4) Solder resist plugging holes, through the solder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com