A class B heat-resistant polyvinyl formal enameled wire insulating varnish and preparation method thereof

A technology of polyvinyl formal and polyvinyl formal resin, which is applied in coatings, epoxy resin coatings, etc., can solve the problems of low heat resistance level and limited popularization and application, achieve high heat resistance level, improve resistance The effects of heat and good physical and chemical technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

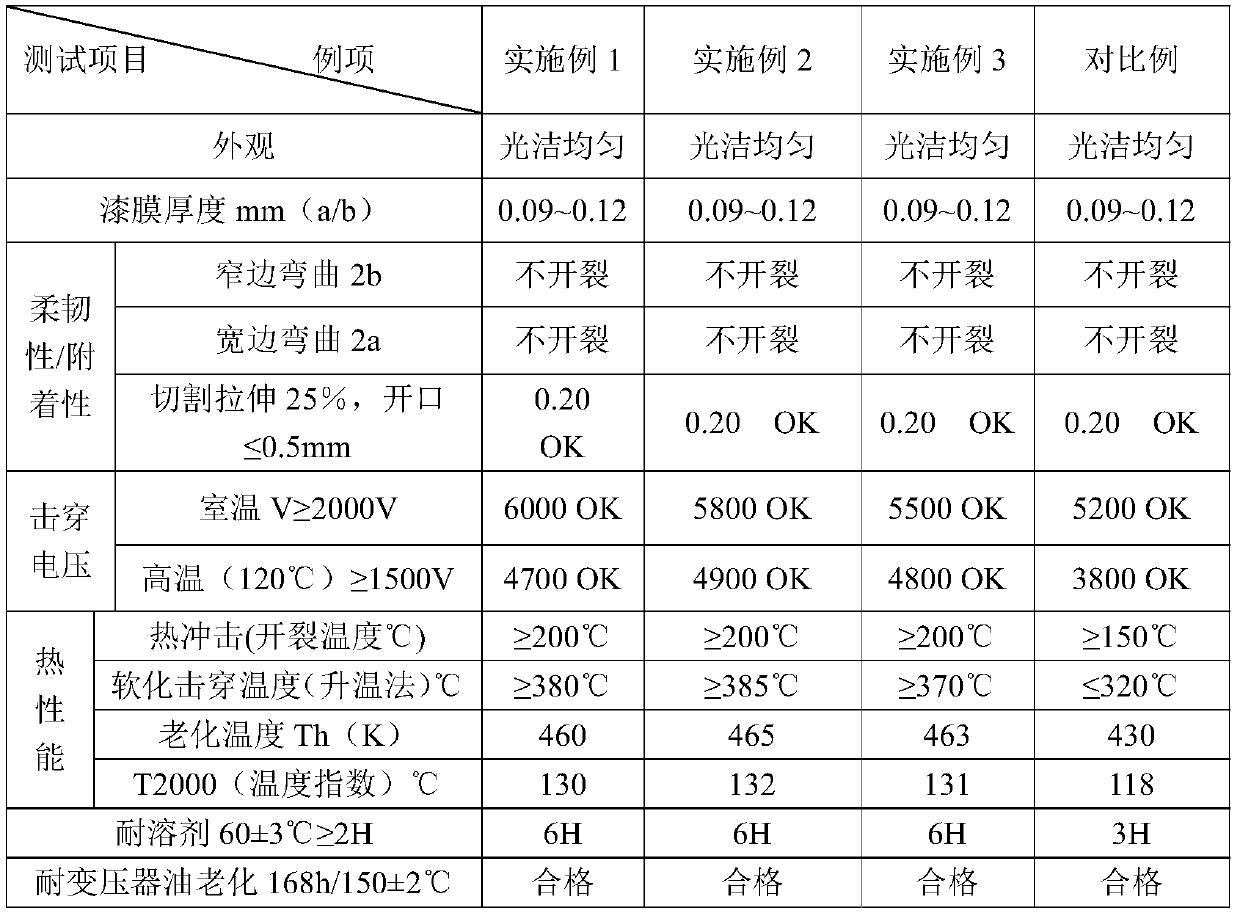

Embodiment 1

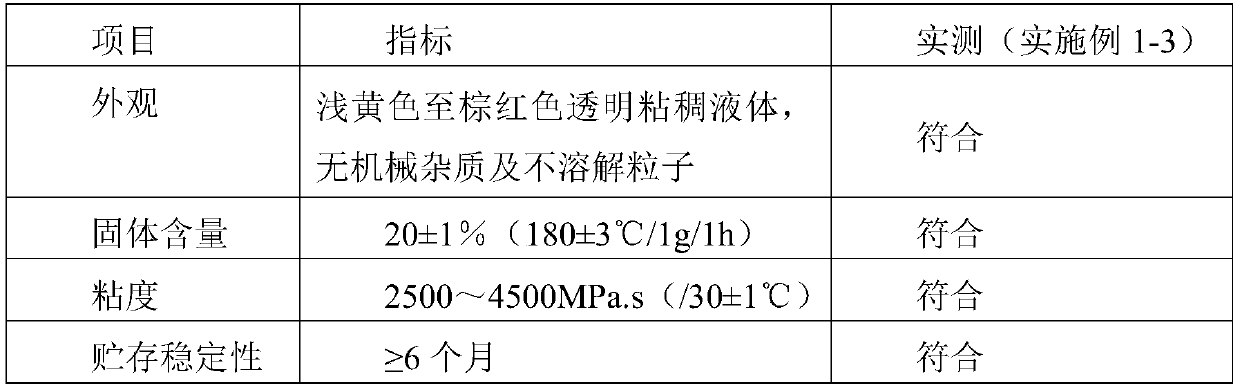

[0024] Preparation of class B heat-resistant polyvinyl formal enameled wire insulating varnish:

[0025] (1) Add 225 parts of cresol, 270 parts of xylene, and 253.8 parts of furfural into the reactor by weight, stir and mix evenly, and make mixed solvent A;

[0026] (2) Take 670.4 parts of mixed solvent A according to the weight ratio, add it to the reaction kettle and stir evenly, heat up to 45°C, gradually add 135 parts of polyvinyl formal resin (PVF) in batches, stir after the addition and heat up to 80°C , keep warm for 3 hours, until the polyvinyl formal resin is completely dissolved, and the semi-finished product B is obtained;

[0027] (3) Take 16.2 parts of mixed solvent A according to the weight ratio and add it to a reaction kettle with a stirrer, add 16.2 parts of 704 epoxy resin, stir evenly and heat up to 60°C, keep it warm for 2 hours, stir until the resin is completely dissolved, and get a semi-finished product C ;

[0028] (4) Take 50.4 parts of mixed solvent...

Embodiment 2

[0034] Preparation of class B heat-resistant polyvinyl formal enameled wire insulating varnish:

[0035] (1) Add 247.7 parts of cresol, 247 parts of xylene, and 247 parts of furfural into the reaction kettle by weight, stir and mix evenly, and make mixed solvent A;

[0036] (2) Take 668.6 parts of mixed solvent A according to the weight ratio, add it to the reaction kettle and stir evenly, heat up to 50°C, gradually add 135 parts of polyvinyl formal resin (PVF) in batches, stir again after adding, and heat up to 85°C , heat preservation for 2.5h, until the polyvinyl formal resin is completely dissolved, and the semi-finished product B is obtained;

[0037] (3) Take 13.5 parts of mixed solvent A according to the weight ratio and add it to the reaction kettle with agitator, add 13.5 parts of 704 epoxy resin, stir evenly and heat up to 65 ° C, keep it warm for 2 hours, stir until the resin is completely dissolved, and get a semi-finished product C;

[0038] (4) Take 44.1 parts ...

Embodiment 3

[0044] (1) By weight ratio, 265 parts of cresol, 220 parts of xylene, and 249.7 parts of furfural were added to the reaction kettle, stirred and mixed evenly, and mixed solvent A was made;

[0045] (2) According to the weight ratio, take 66.6 parts of mixed solvent A66.6 into the reaction kettle and stir evenly, heat up to 55°C, gradually add 135 parts of polyvinyl formal resin (PVF) in batches, and then stir and heat up to 90°C, keep warm for 2 hours, until the polyvinyl formal resin is completely dissolved, and the semi-finished product B is obtained;

[0046] (3) Take 10.8 parts of mixed solvent A according to the weight ratio and add it to a reaction kettle with a stirrer, add 10.8 parts of 704 epoxy resin, stir evenly and heat up to 70°C, keep warm for 1.5h, stir until the resin is completely dissolved, and get semi-finished product C;

[0047] (4) Take 37.8 parts of mixed solvent A according to the weight ratio and add it to a reaction kettle with a stirrer, add 16.2 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com