Auxiliary device for installing primary truss during construction of truss type roof, and installation method

A technology for auxiliary devices and main trusses, applied in the field of auxiliary devices for installing main trusses and installing main trusses, it can solve problems such as harsh environment, waste, and insecurity, and achieve good working environment, simple and convenient installation and operation process, and large space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

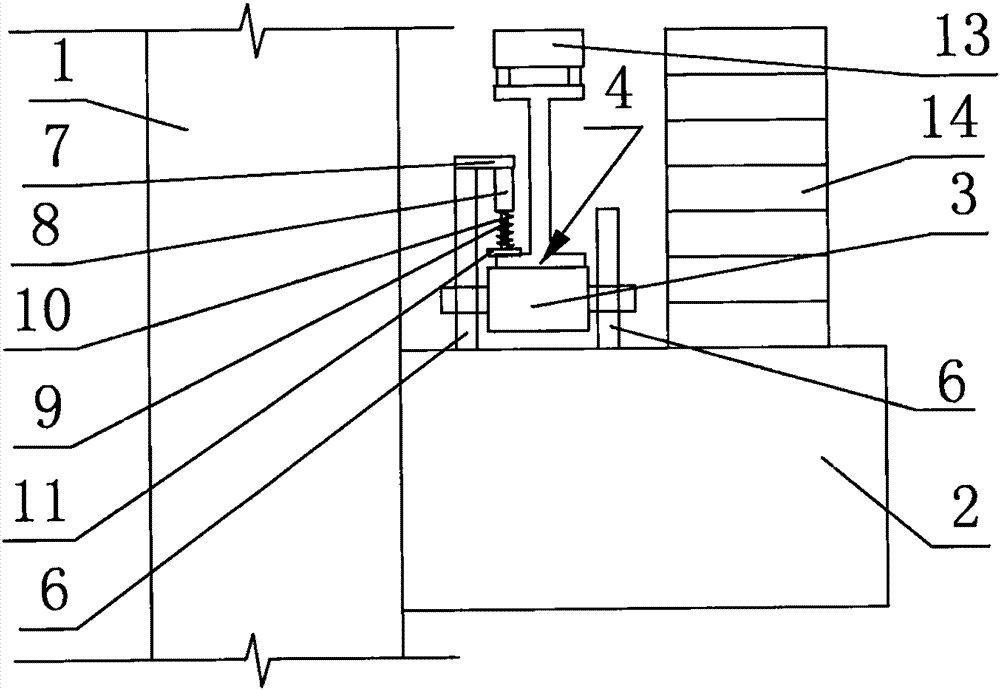

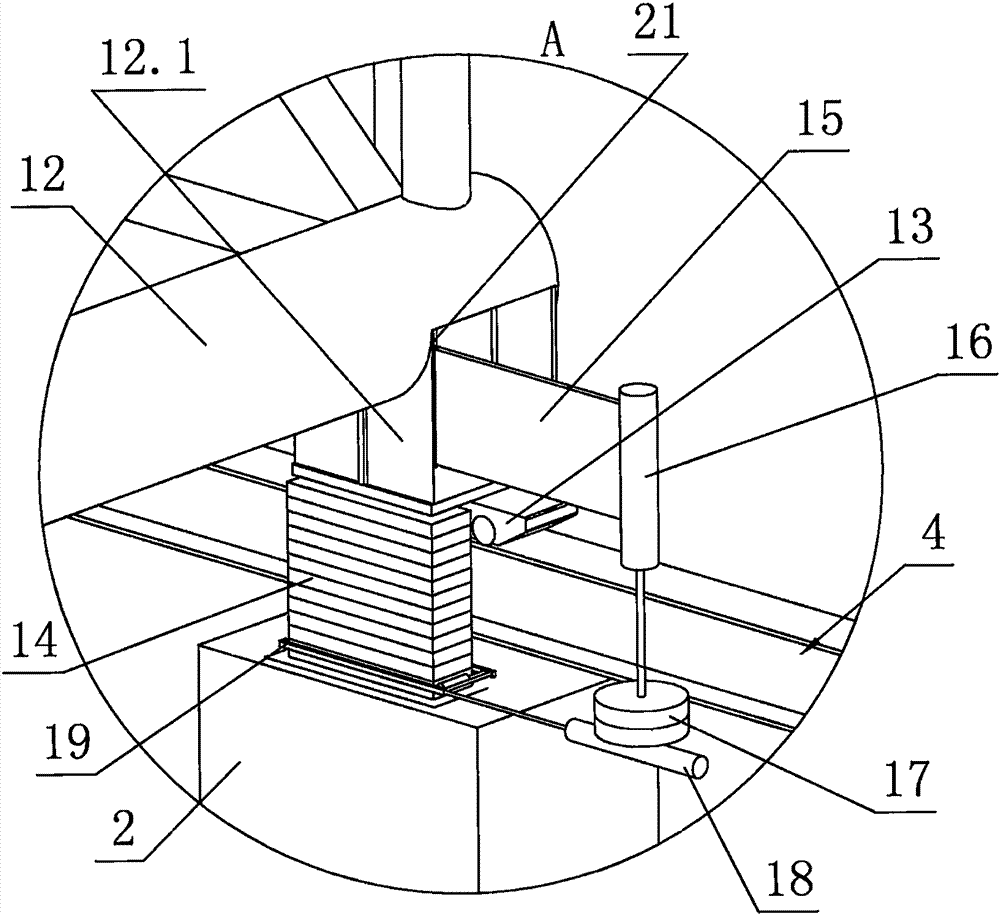

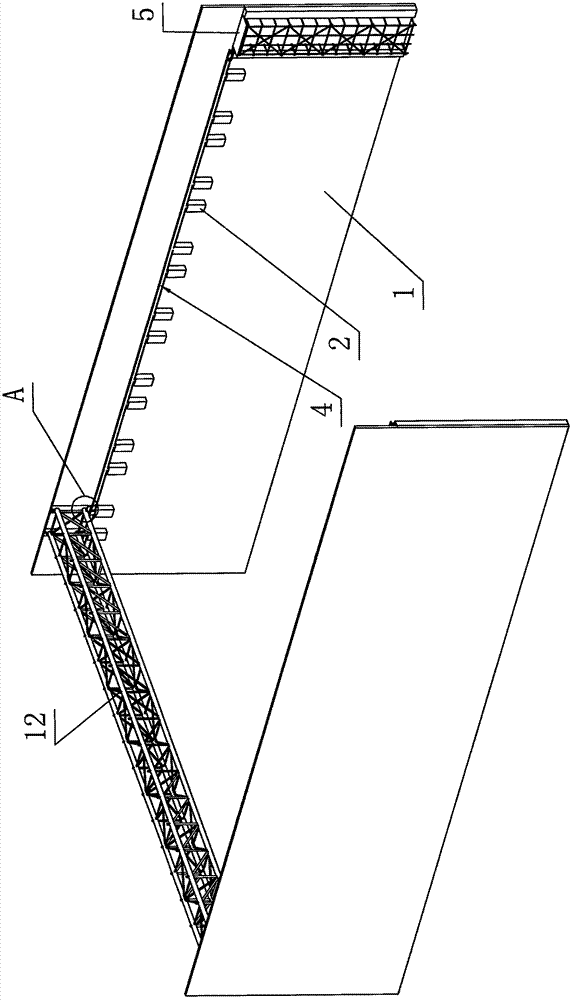

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the present invention is an auxiliary device for installing the main truss when constructing a large-span truss-type steel structure roof. It includes four groups of manipulators for extracting backing plates 14, and each group of manipulators includes a fixed plate 15, a vertical cylinder 16, a rotating Cylinder 17 and transverse cylinder 18.

[0032] The fixed plate 15 is detachably connected to one leg 12.1 of the main truss 12, each leg 12.1 is provided with a vertical groove 21 with an open upper end and a closed lower end, and an electromagnetic vertical convex strip 22 is provided on one side of the fixed plate 15, Electromagnetic vertical protrusions 22 are inserted into vertical grooves 21, and when the manipulator needs to be fixed to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com