Four-row ball slide rail and knife type lifting bracket

A technology of ball slides and balls, which is applied in the direction of machines/brackets, supporting machines, bearings for linear motion, etc., can solve the problems of unstable inner rail position, thick ball slides, and can not be used alone, etc., to increase Wide range of applications, compact bracket, and the effect of eliminating uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

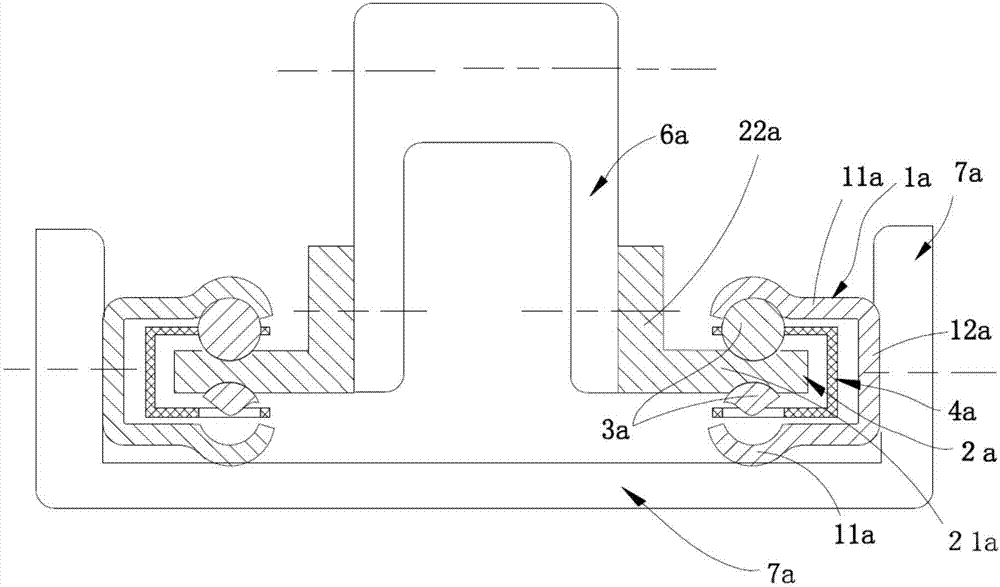

[0071] See Figure 2 to Figure 8 shown and emphatically see figure 2 , a group of four-row ball isosceles trapezoidal distributed thin ball slide rails B group, which is specially used as the ball slide rail in the bracket in the display lifting support frame (meaning that its application field is specific), it is characterized in that it includes:

[0072]An outer rail 1, including two adjacent and generally parallel plate-shaped raceway plates 11 (the two raceway plates 11 are generally parallel, and at the same time, an accommodation space is formed between them), the two raceway plates 11 together The longitudinal edges of the sides are mutually bent and extended to form a connected body part 12 (for example but not limited to this: that is, the outer rail 1 is generally approximately U-shaped when viewed from a cross section, and the connected body part 12 is equivalent to a U-shaped The two raceway plates 11 are equivalent to the U-shape to remove the remaining two sec...

Embodiment 2

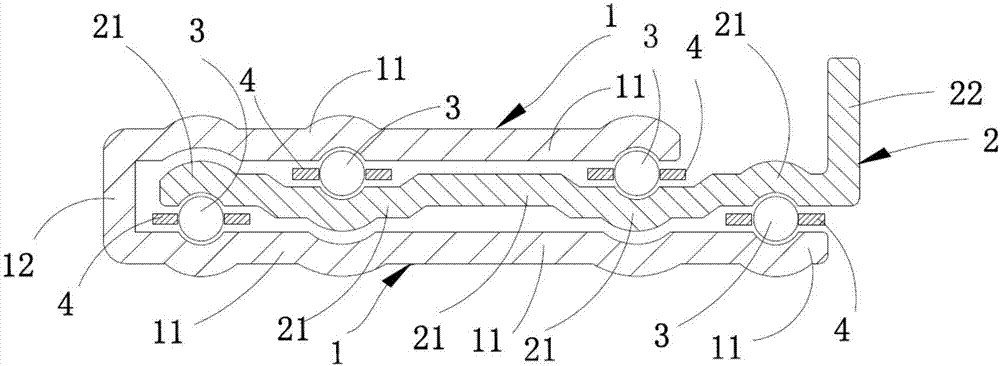

[0088] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0089] like Figure 9-15 As shown, there are four rows of balls and corresponding elongated ball racks 4, each row of balls is arranged along the longitudinal direction of the slide rail, each row of balls includes a plurality of balls 3 (for example, steel balls are used for balls 3), and each row of balls The balls 3 are all spaced apart and accommodated in the corresponding number of accommodations on the corresponding bead holders 4 (such as but not limited to, the structure of the bead holders 4 is a strip-shaped thin steel sheet with a row of accommodation holes corresponding to the number of balls 3 in the ball row). In the hole; from the cross-section of the slide rail, the connecting lines between the centers of the four rows of balls generally form a parallelogram (the centers of the four balls belonging to the four rows of balls are connected by a straigh...

Embodiment 3

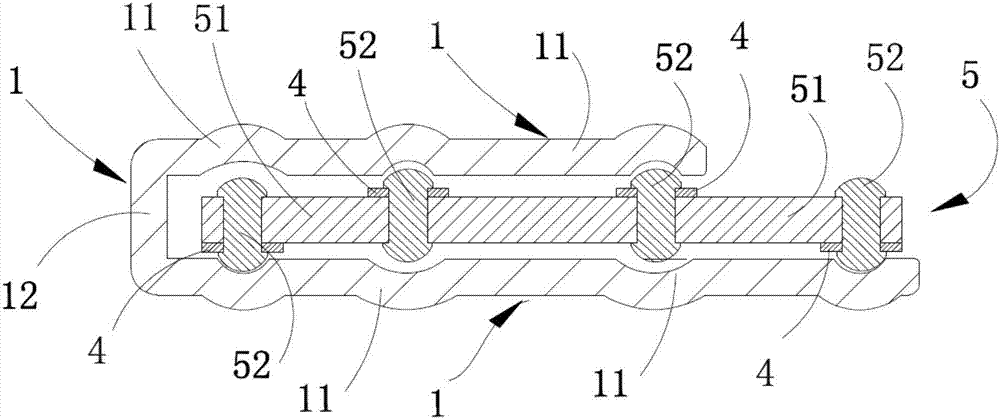

[0094] This embodiment is basically the same as Embodiment 2, the difference is:

[0095] Four rows of balls and corresponding elongated ball racks 4, each row of balls are arranged along the longitudinal direction of the slide rail, each row of balls includes a plurality of balls 3 (such as steel balls 3), each row of balls 3 Be spaced, accommodated and held in the corresponding number of accommodation holes on the corresponding bead rack 4 (such as but not limited to, the structure of the bead rack 4 is a strip-shaped thin steel sheet with a row of accommodation holes corresponding to the number of balls 3 in the ball row); Viewed from the cross-section of the slide rail, one side of the raceway part 21 plate body and an adjacent raceway plate face jointly interfere with two rows of balls (two ball passages that jointly clamp and interfere with the row of balls are formed) ) and the line connecting the centers of the two rows of balls is defined as the first line connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com