Online monitoring and analysis system for environmental variables of transformer production workshop

A technology for production workshops and analysis systems, applied in signal transmission systems, instruments, measuring devices, etc., can solve the problems that transformers cannot provide help, require manual operation, and complicated operations, so as to facilitate process data recording, data analysis, and measurement The results are accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

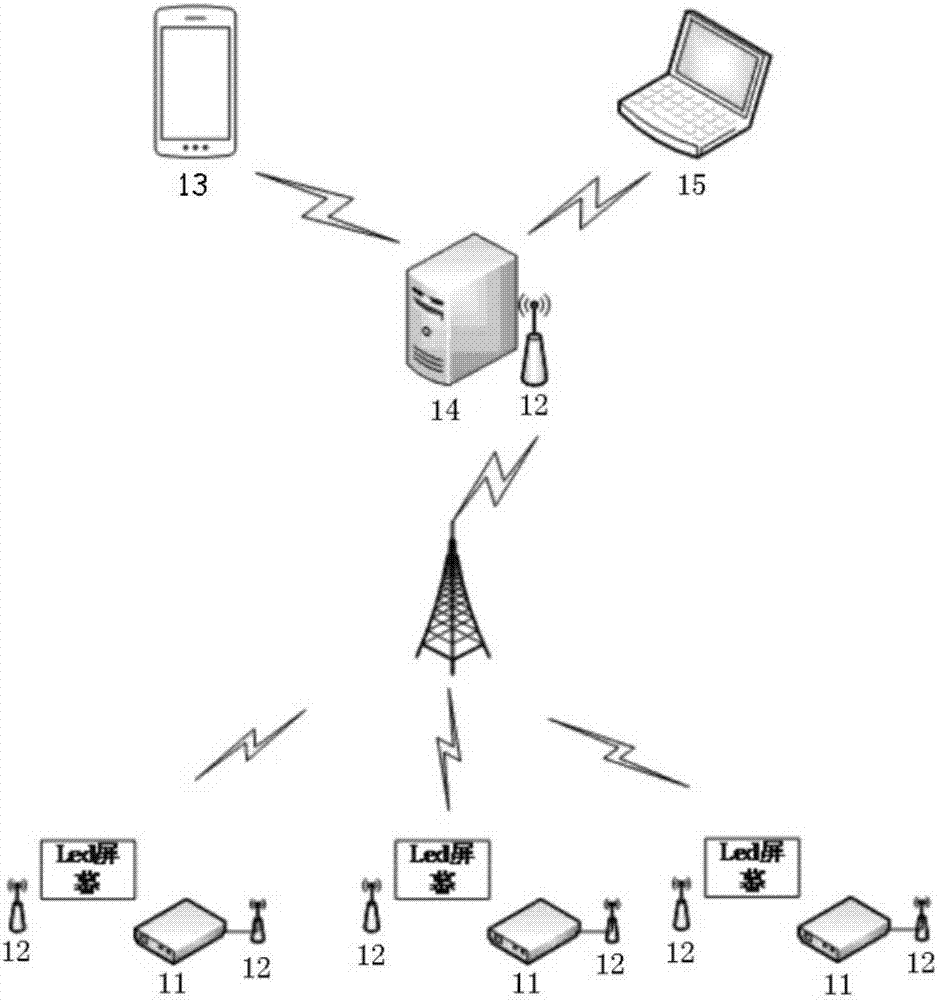

[0029] Such as figure 1 As shown in , it is a schematic diagram of the overall structure of the online monitoring and analysis system for the environmental quantity of the transformer production workshop. In the figure, the environmental quantity detection device 11 collects the environmental quantity value of the production workshop in real time, communicates with the remote server 14 through the GPRS communication module 12 and wireless network, and uploads the workshop environmental quantity data to the remote server. The remote server 14 analyzes the received data through the data analysis module, automatically stores the environmental quantity data of the workshop every day through the data storage module, and sends the analysis results to the LED display screen of the production workshop for real-time display. In addition, management personnel c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com