Longitudinal wave mode electromagnetic ultrasonic pipeline internal inspection spiral guided-wave transducer

An electromagnetic ultrasonic and transducer technology, which is applied in the direction of material analysis, instruments, and measuring devices using sound waves/ultrasonic waves/infrasonic waves, and can solve problems such as being single and unable to meet the actual needs of electromagnetic ultrasonic pipeline inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

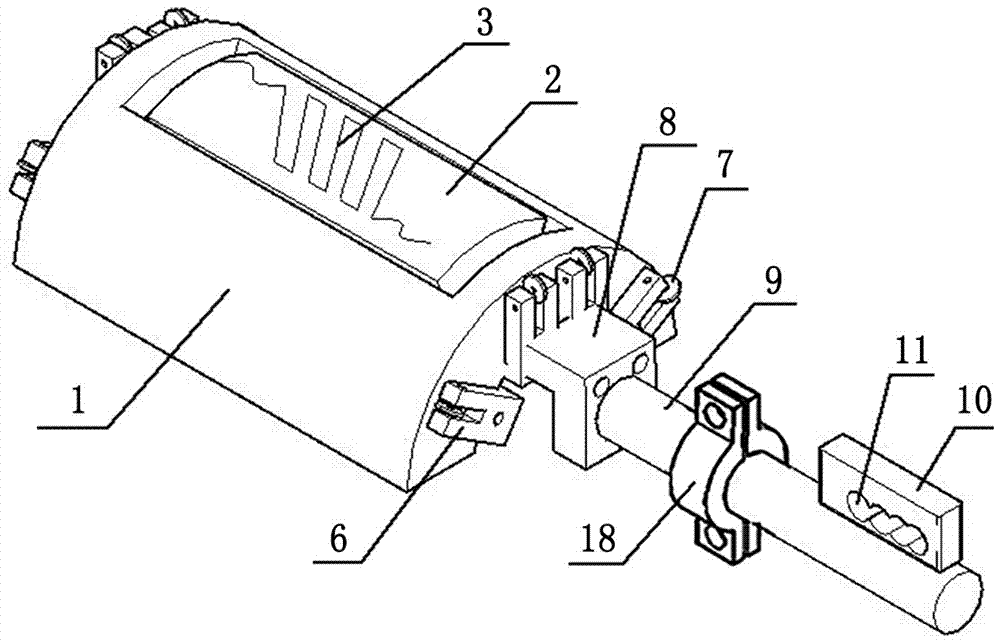

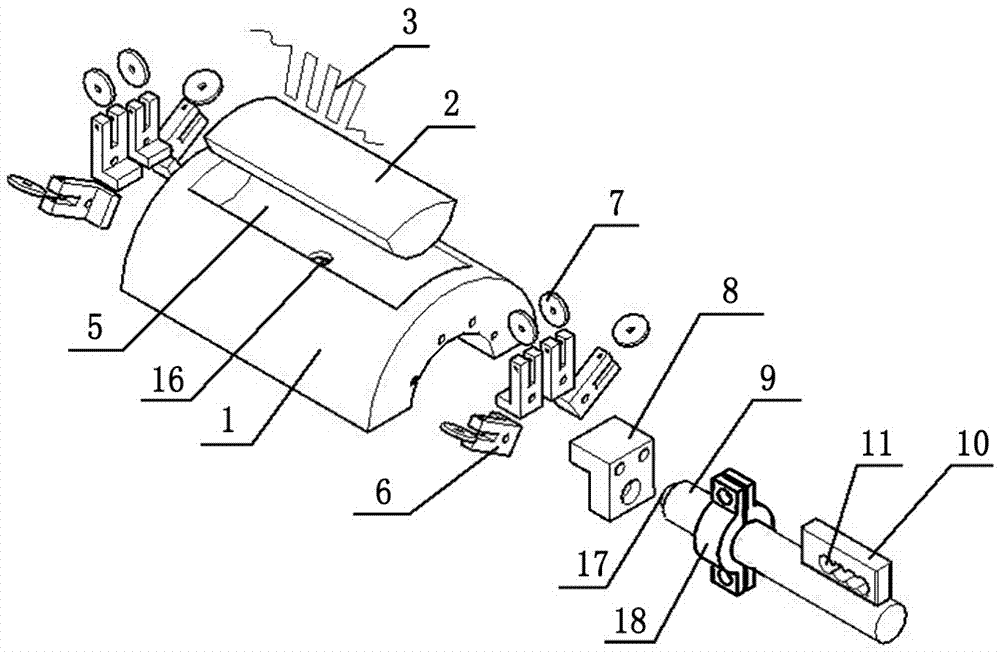

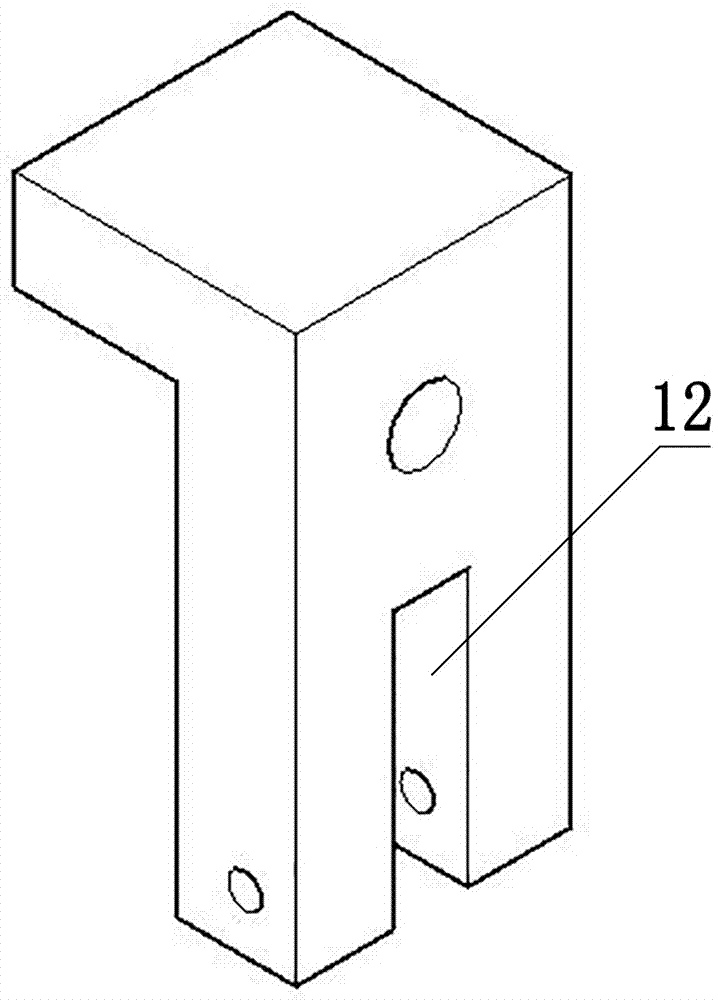

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 A longitudinal wave mode electromagnetic ultrasonic pipeline detection spiral guided wave transducer is shown, including a protective shell 1, a holding structure, a walking support structure, a permanent magnet 2 and a coil 3, the protective shell 1 is arched, and the two sides of the protective shell 1 The plane is connected with a walking support structure. The walking support structure is composed of a support 6 and a pulley 7. The support 6 is L-shaped. The upper plane at the lower corner is close to the inner arc of the protective shell 1. There is a square groove 12 in the middle of the upper side. Pulley 7 is installed in the square groove 12. The supporting member 6 is connected to the planes on both sides of the protective shell 1 , and the pulley 7 is installed on the upper part of the supporting member 6 . The other side of the walking support structure on one si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com