Electric motors, electric vehicles

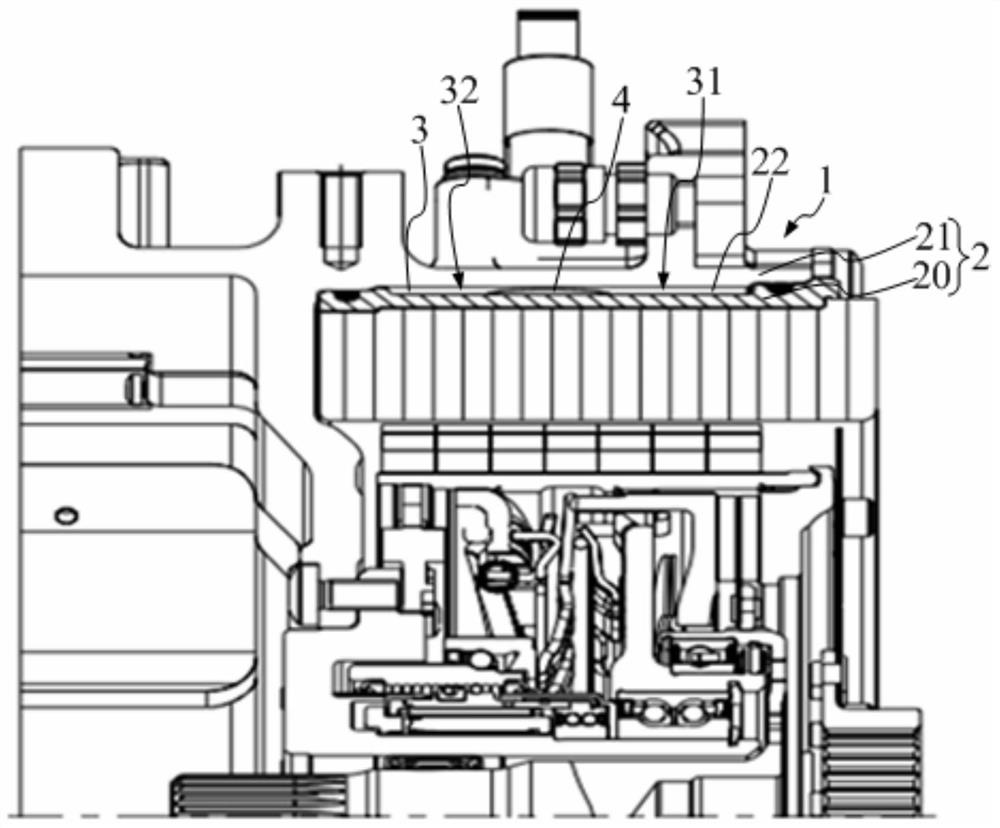

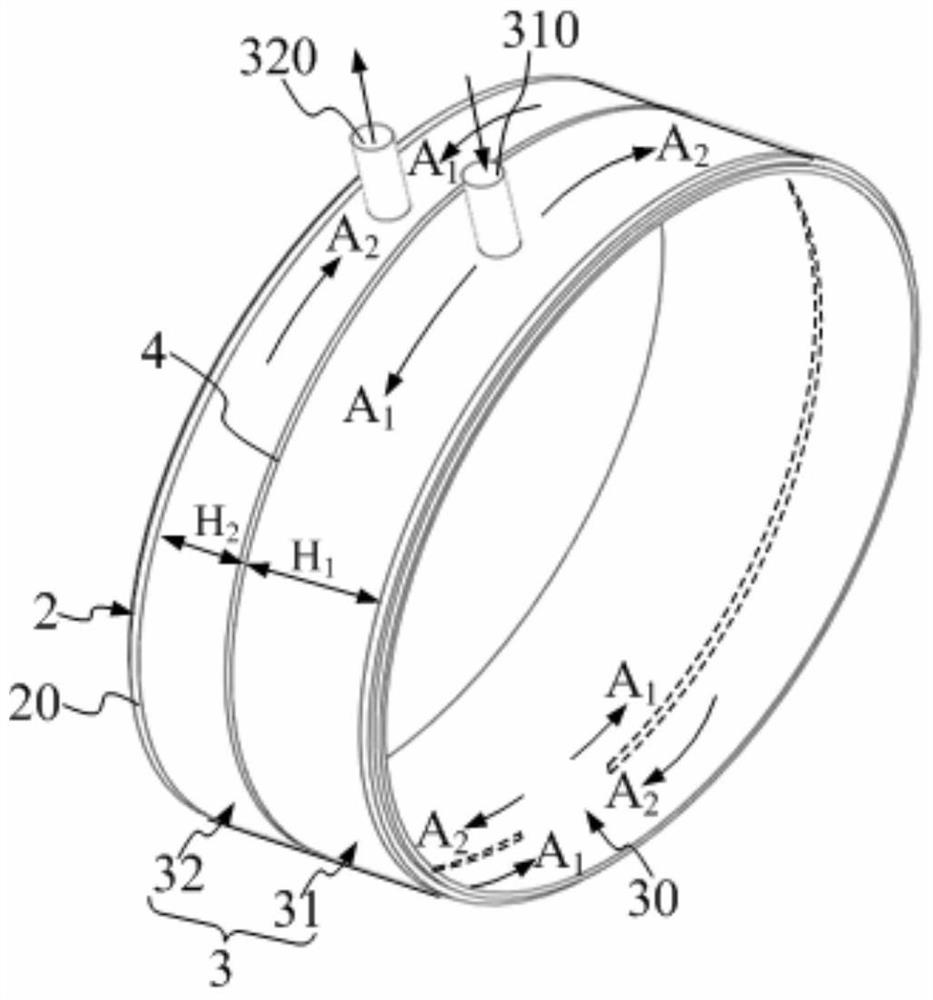

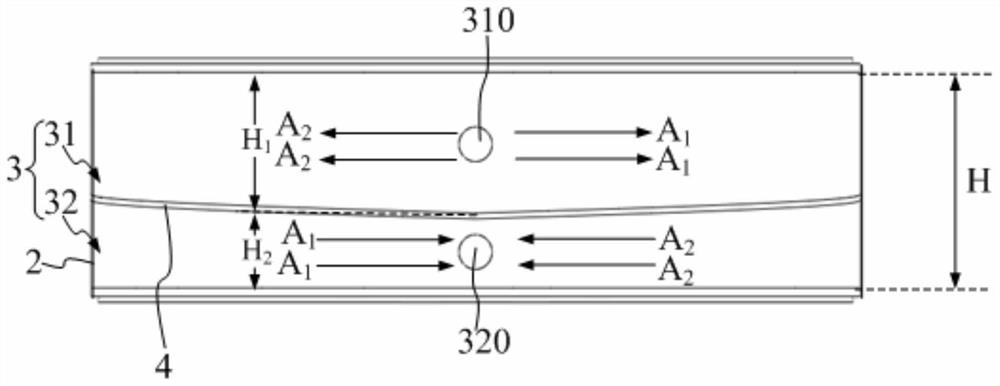

A cooling channel and axial width technology, applied in the direction of electric vehicles, motors, electric components, etc., can solve the problems of local overheating of motors, reduction of motor working efficiency, power loss, etc., to reduce power loss, eliminate local overheating, and improve work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Aiming at the problems existing in the prior art, the inventor found through research that the inlet and outlet of the cooling channel are located on both sides of the partition, which forms a dead water zone near the partition between the inlet and the outlet.

[0023] During the coolant circulation process, due to the partition, the low-temperature coolant flowing from the input port will flow towards the output port, and only a small amount of low-temperature coolant will flow to the cooling channel area between the partition and the input port, so that The coolant in the area of the cooling channel between the partition and the inlet is in a stagnant state for a long time.

[0024] Correspondingly, the low-temperature coolant from the input port flows into the high-temperature coolant after flowing through the cooling channel, and the high-temperature coolant directly flows into the output port and is output, while only a small amount of high-temperature coolant fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com