Dust removing mechanism of glass fiber cloth gluing device

A glass fiber cloth and dust removal chamber technology, applied in the field of machinery, can solve problems such as affecting the quality of glue, hindering the adhesion of glue, affecting the purity of glue, etc., so as to improve the quality of glue, avoid dust hindering the adhesion of glue, improve The effect of the dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

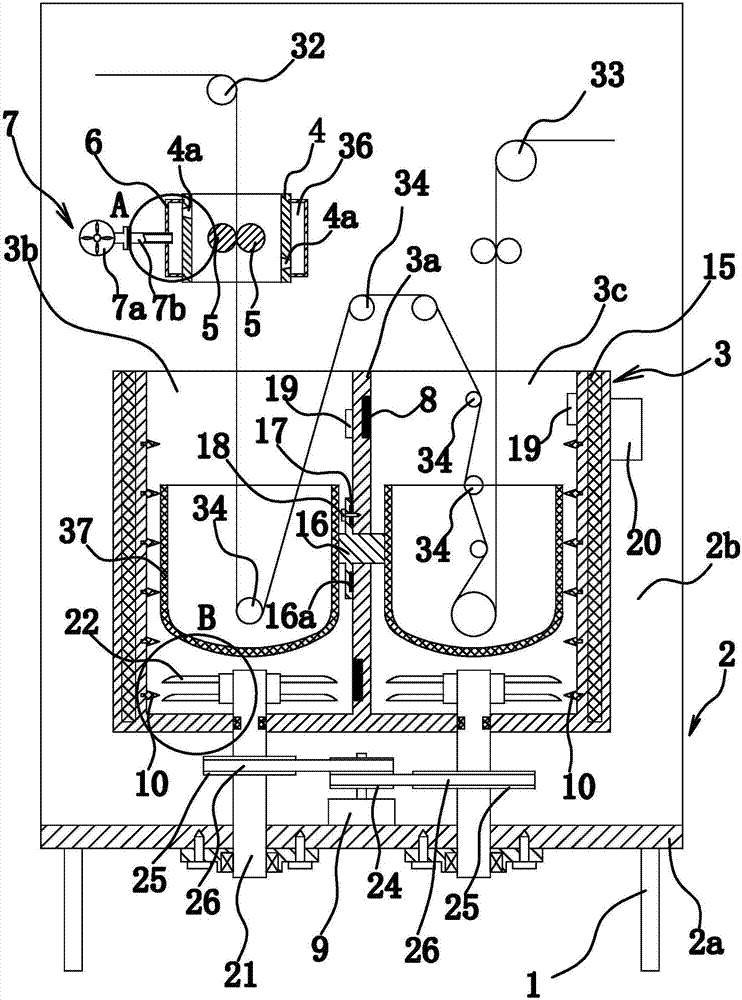

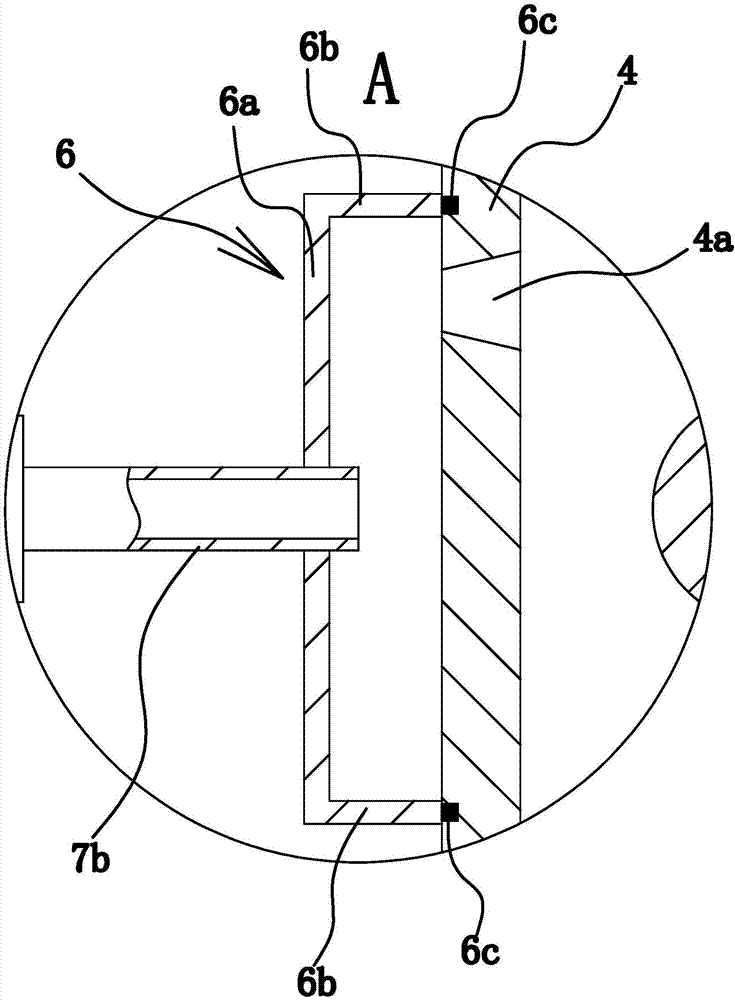

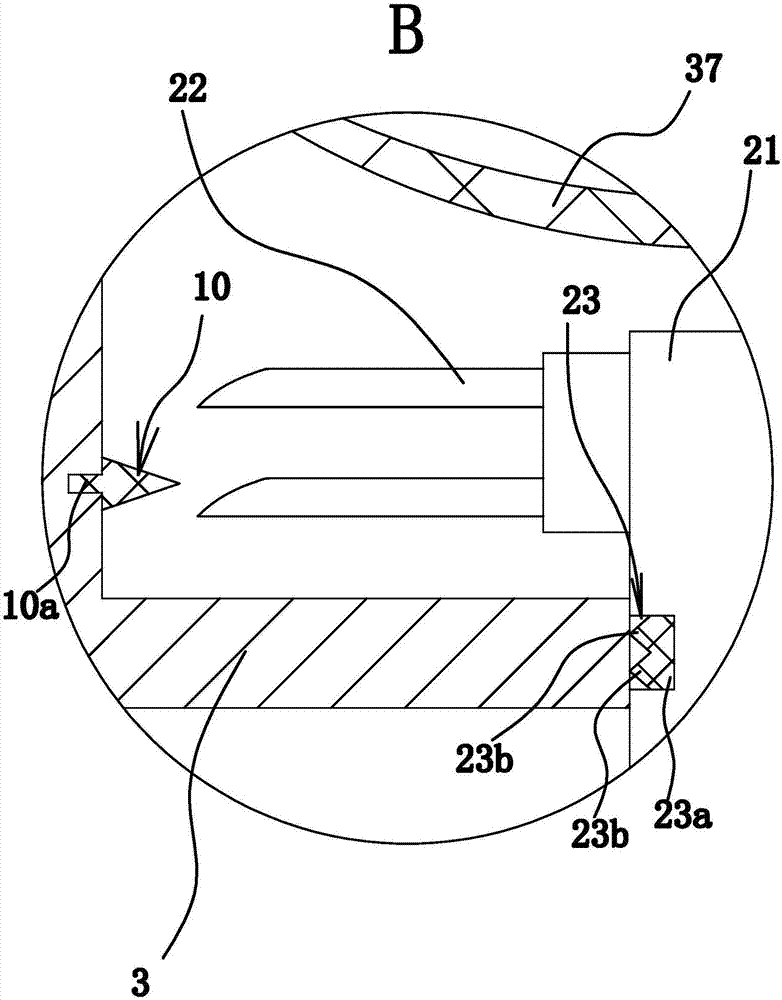

[0028] Such as Figure 1 to Figure 6 As shown, the glass fiber cloth gluing device consists of a bracket 1, a workbench 2, a tank body 3, an air suction ring 4, a roller shaft 5, a sealing ring 6, a negative pressure piece 7, an electric heating plate 8, a motor 9, and a crushing head 10. Composition of support block 11, piston 12, push plate 13, spring 14, etc. Wherein, the electric heating plate 8 is an existing product, which can be bought in the market.

[0029] Specifically, the workbench 2 is located on the support 1, such as figure 1 As shown, the workbench 2 is L-shaped, and the workbench 2 includes a horizontally arranged support part 2a and a vertically arranged support part 2b. Both the support part 2a and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com