Thickness control method of aluminum plate hot mill adopting electric and hydraulic screwing down

A technology of hydraulic pressure reduction and thickness control, applied in rolling mill control devices, metal rolling, metal rolling, etc. Smooth running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for controlling the thickness of an aluminum plate hot rolling mill using electric and hydraulic pressure, the method comprising the following steps:

[0046] Step 1: Adjust the initial setting of the roll gap so that the deviation of the predicted rolling force in the last two passes is less than 200KN;

[0047] Step 2: During the rolling process of the penultimate pass, the roll gap and rolling force are accumulated in real time;

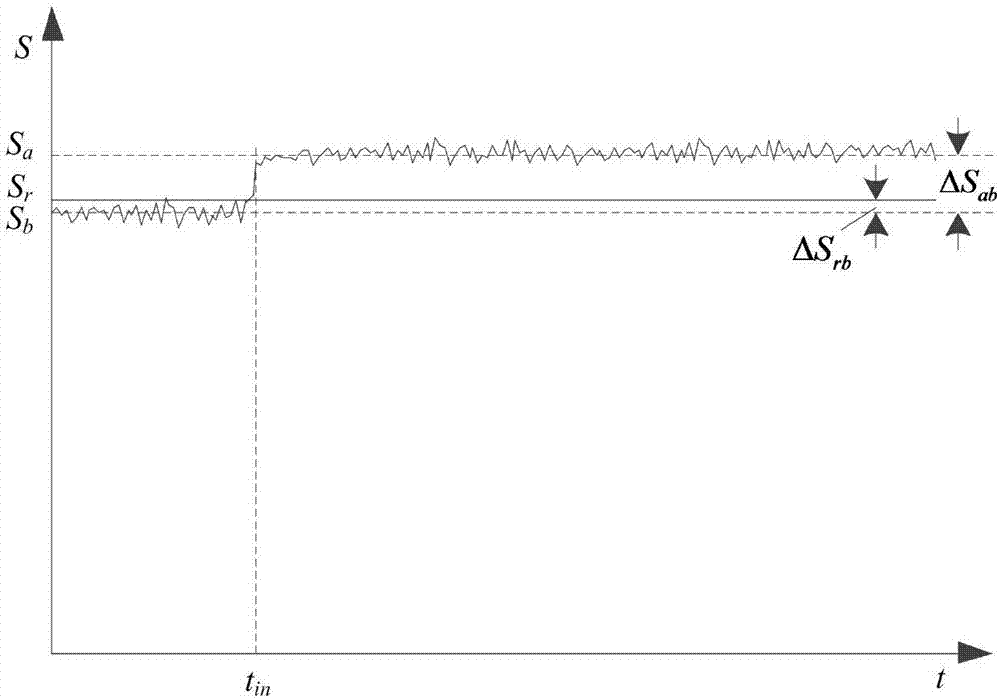

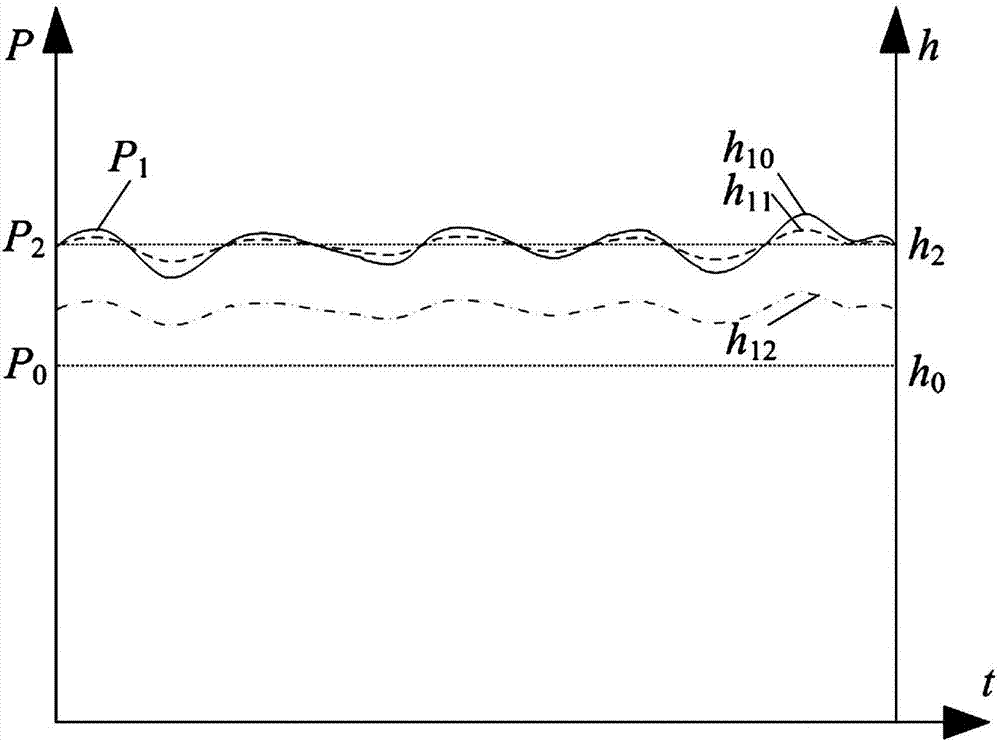

[0048] Step 3: After the penultimate pass rolling is completed, calculate the average roll gap S before the penultimate pass slab bites into the rolling mill 2b , the average roll gap S after the penultimate pass slab bites into the rolling mill 2a and the average rolling force P of the penultimate pass 2ave , to obtain the bounce amount ΔS of the electric roll gap before and after the penultimate pass of the slab biting 2ab ;

[0049] The bounce amount of the electric roll gap before and after the penultimate pass of the slab ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com