The Method of Making High-Strength Bolt Holes Quickly

A technology of high-strength bolts and bolt holes, which is applied in the production of bolt holes and the field of rapid production of high-strength bolt holes, can solve the problems of difficult control standards, etc., and achieve the effects of effective elimination and convenient fixing, increased repeated service life, and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The detailed steps of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] A method for rapidly manufacturing high-strength bolt holes, comprising the steps of:

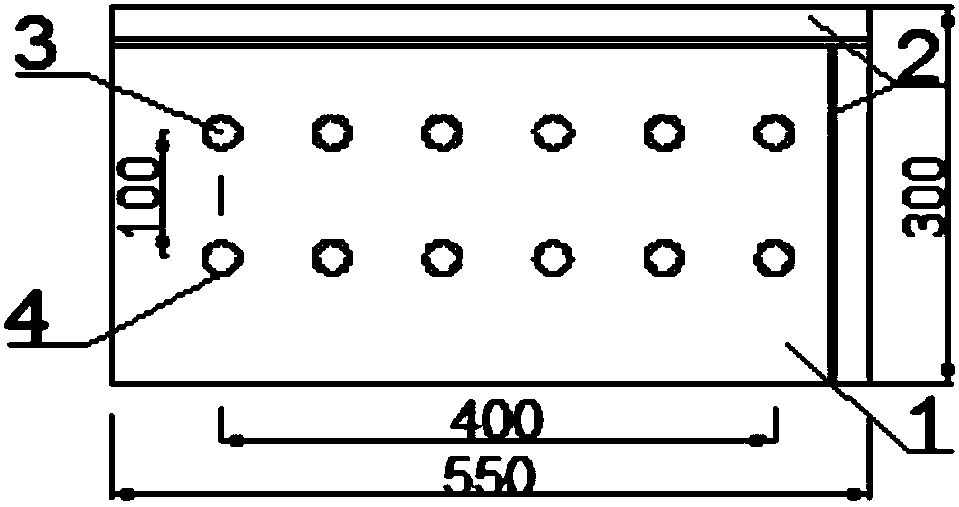

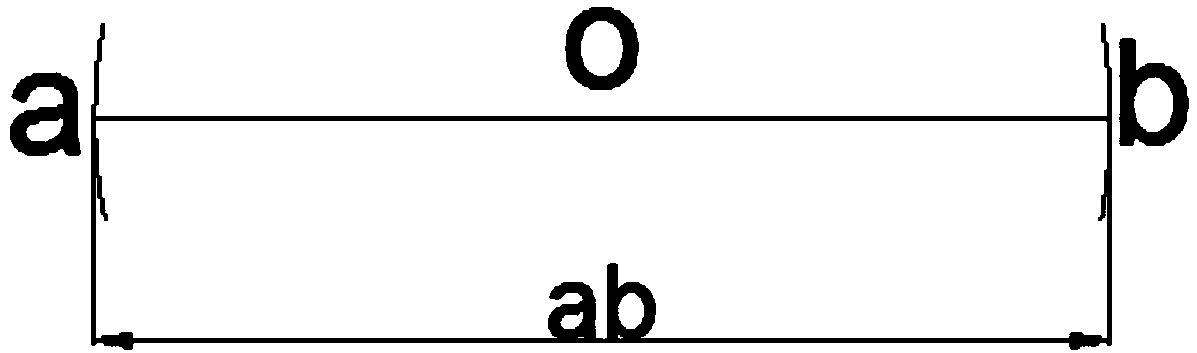

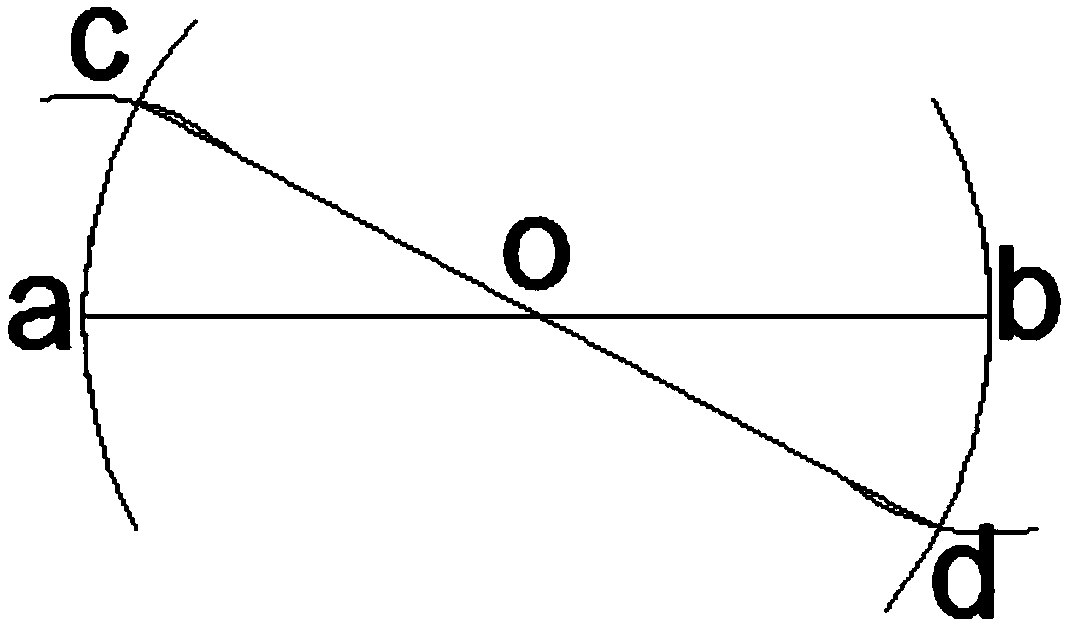

[0021] Step 1. According to the attached figure 1 The dimensions of the bolt hole groups shown in the legend for the bolt hole template shown, determine the diagonal ab of the rectangle, Take a piece of galvanized steel plate with a corresponding size of δ=1.0mm, use drawing rules to draw a semicircular arc on the galvanized steel plate with point o as the center, and the radius length is ab / 2, randomly pick a point a on the arc, connect ao and The arcs intersect to get point b, draw the line aob, and determine the diagonal (as shown in the attached figure 2 shown).

[0022] Step 2. Take a and b as the center of the circle and 100mm as the radius (the radius of 100mm is the distance between the two rows of bolt holes in the legend of the bolt hole t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com