Preparation method of basic copper nitrate

A copper nitrate, basic technology, applied in the direction of copper nitrate, etc., can solve the problems of unstable product properties, harsh equipment requirements, complicated process, etc., and achieve the effect of low cost, stable product properties and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

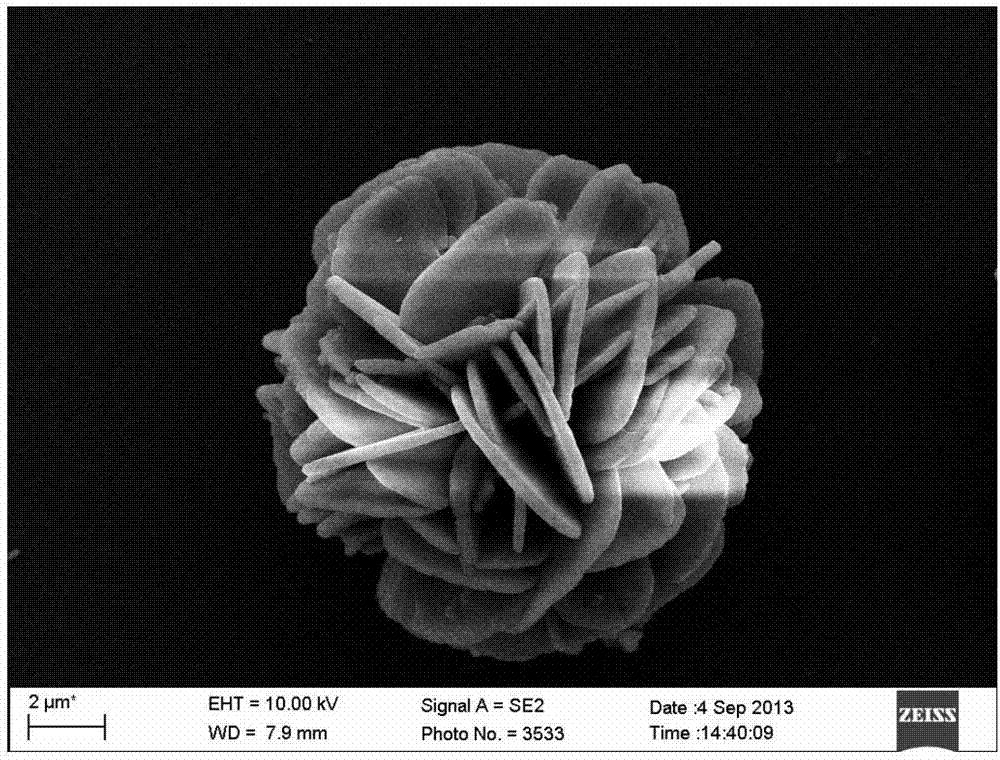

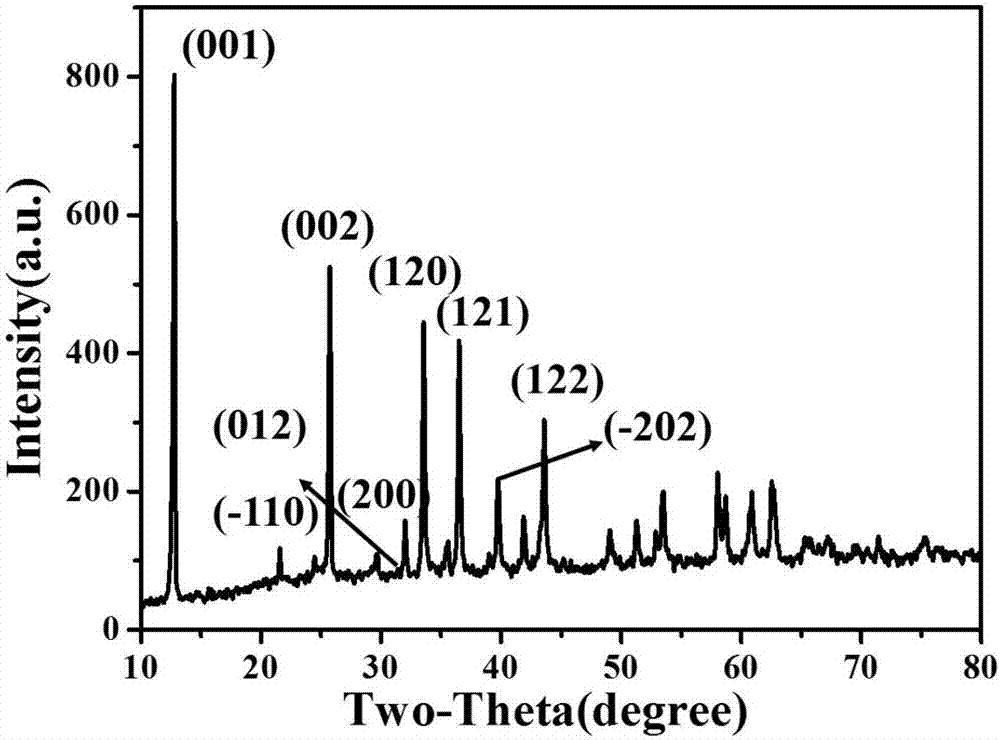

[0025] Example 1: Prepare 40ml of copper nitrate aqueous solution with a concentration of 0.75mol / L at normal temperature, add 30mL of 1,3-propylenediamine aqueous solution with a concentration of 0.012mol / L to it under stirring, continue to stir for 10min, and then Let stand for 2h. After filtering, washing, and drying at 60°C for 12 hours, 5.3 g of basic copper nitrate was obtained, with a yield of 72%. The shape of the product was flower-like, and the average particle size was 6 μm. The scanning electron micrographs and XRD patterns of the product are as follows: figure 1 , figure 2 shown.

Embodiment 2

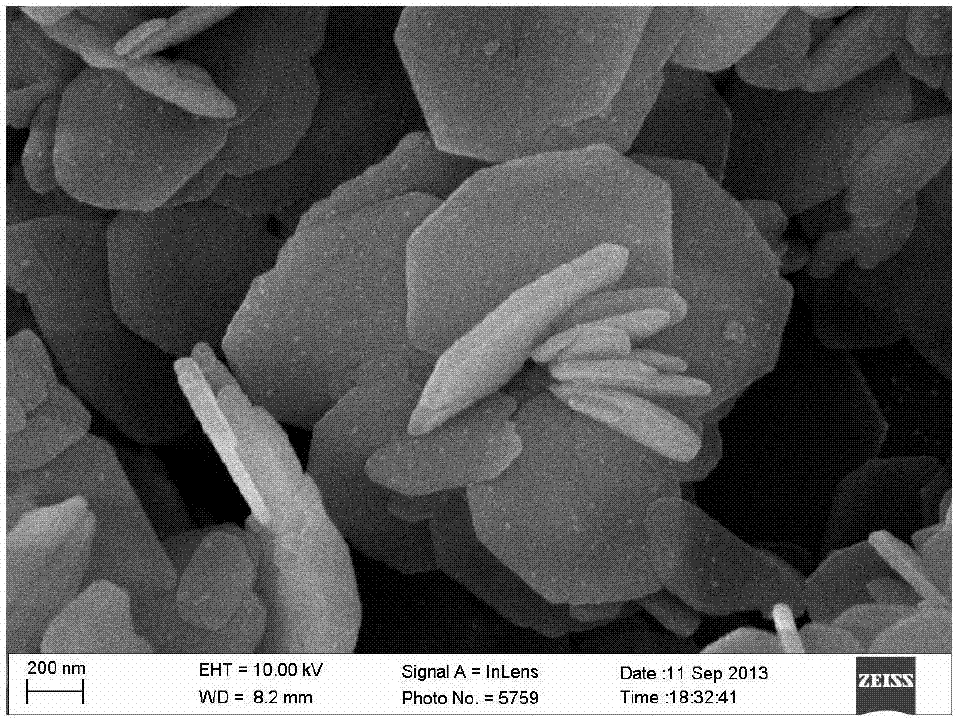

[0026] Example 2: Prepare 40ml of copper nitrate aqueous solution with a concentration of 0.75mol / L at normal temperature, add 30mL of 1,3-propylenediamine aqueous solution with a concentration of 0.008mol / L to it under stirring, continue to stir for 10min, and then Let stand for 2h. Filtrate, wash, and then dry at 60°C for 12 hours to obtain 4.8 g of basic copper nitrate, with a yield of 66%. The product has a flaky appearance and an average particle size of 2 μm. The scanning electron microscope photograph of the product is as image 3 shown.

Embodiment 3

[0027] Example 3: Prepare 40 ml of copper nitrate aqueous solution with a concentration of 0.75 mol / L at room temperature, add 30 mL of 1,3-propylenediamine aqueous solution with a concentration of 0.004 mol / L to it under stirring, continue stirring for 10 min, and then Let stand for 2h. Filter, wash, and then dry at 60°C for 12 hours to obtain 4.2 g of basic copper nitrate microspheres, with a yield of 58%. The product has a flake shape and an average particle size of 10 μm. The transmission electron microscope pictures of the product are as follows: Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com