Electrothermal film glass tube preheating device

A technology of preheating device and glass tube, applied in the field of electric heating film glass tube preheating device, can solve the problems of uneven heating, low viscosity of electric heating film and glass tube, etc. Effect of Radiation Range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

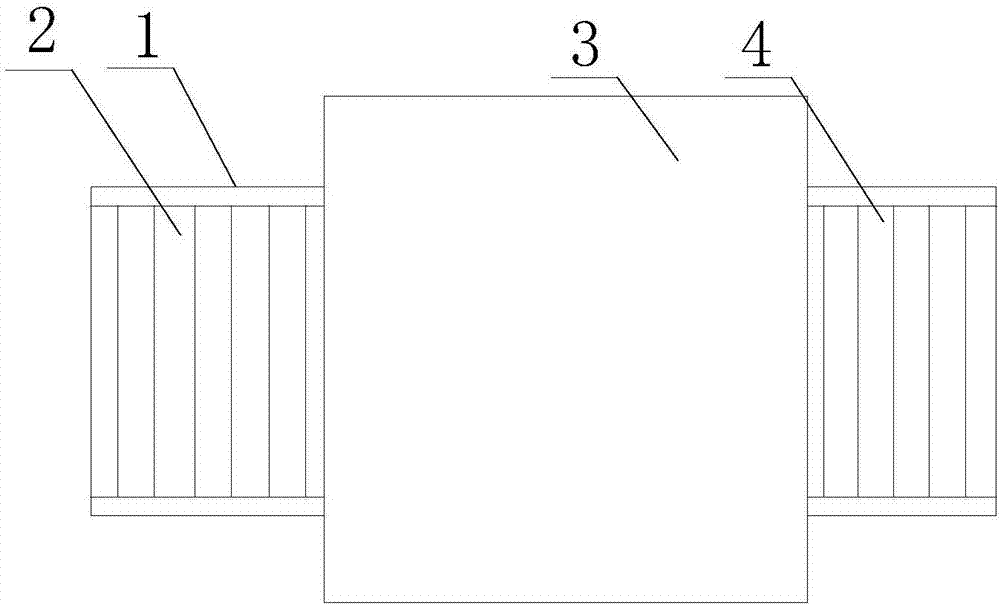

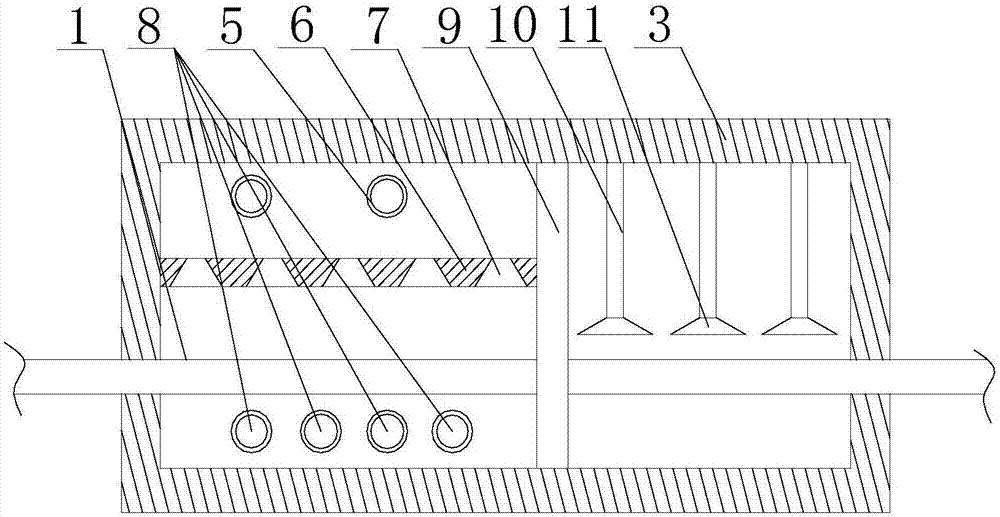

[0022] Such as Figure 1~2 As shown, this embodiment includes two conveyor belts 1 parallel to each other, and a metal mesh 2 is arranged between the two conveyor belts 1, and also includes a processing chamber 3 and a partition 9. Along the moving direction of the conveyor belt 1, the partition 9 The processing chamber 3 is divided into a preheating chamber and a heating chamber, two conveyor belts 1 move through the preheating chamber and the heating chamber, a plurality of hot air pipes 10 are arranged on the upper section of the preheating chamber, and the The air nozzle 11 of the hot air pipe 10 faces the metal mesh 2, two upper air pipes 5 facing the upper surface of the metal mesh 2 are arranged in the heating chamber, and a plurality of positive air pipes 5 are arranged in the heating chamber. For the lower air pipe 8 on the lower surface of the metal mesh 2, a baffle 6 is arranged between the two upper air pipes 5 and the upper surface of the metal mesh 2, and a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com