Method for preparing anti-glare coated glass by solution chemistry

A coated glass, anti-glare technology, applied in the preparation of anti-glare coated glass, non-conductive anti-glare coated glass field, can solve the problems of anti-glare glass can not be tempered, expensive equipment, etc., to achieve excellent resistance to ultrasonic cleaning, simple equipment, The effect of excellent uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: have the preparation of low refractive index coating solution

[0036] 15 g CH 3 Si(OCH 3 ) 3 and 10 grams (CH 3 ) 2 Si(OCH 3 ) 2 Dissolve in 370 grams of absolute ethanol, add 1.5 grams of alumina powder with a particle size of 100 nanometers, stir evenly, then add 1.0 grams of a mixture of 70 wt% nitric acid and 10 grams of deionized water, and stir for 5 hours to obtain a solution a.

Embodiment 2

[0037] Embodiment 2: Pulling method prepares anti-glare film

[0038] Put solution a in a 500ml beaker and put it into a pulling machine, immerse the cleaned and dried 1.8×70×150 mm glass substrate in solution a, pull it at a speed of 2.5 mm per second, and then heat it in an oven to Keep at 350°C for 30 minutes to obtain an anti-glare coating with a thickness of about 150 nanometers.

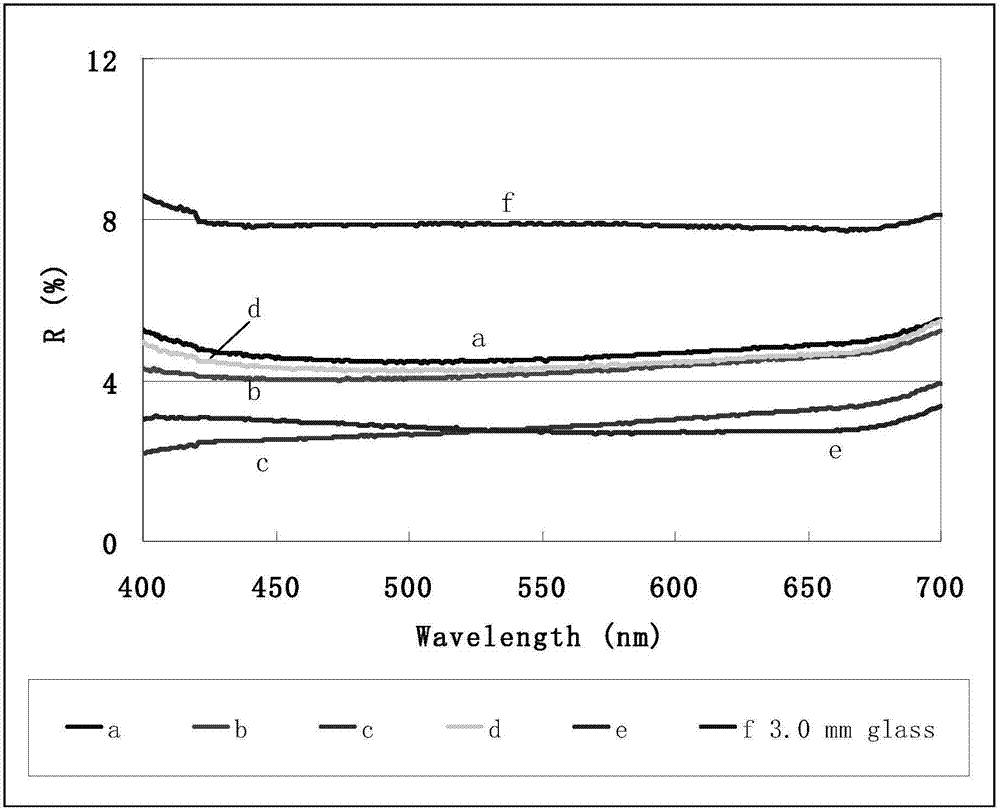

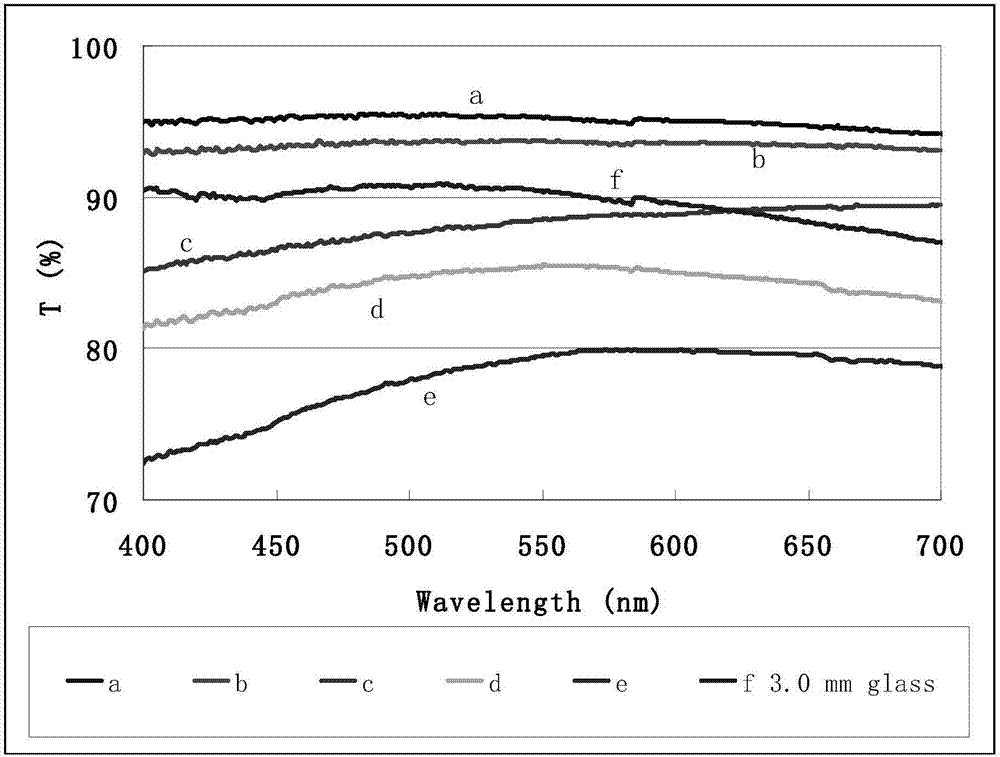

[0039] Referring to the above method, coating solutions using different precursor compounds can be prepared, and non-conductive anti-glare coatings with different film thicknesses can be prepared by the pulling method. The coated glass prepared in this way has excellent resistance to ultrasonic cleaning and physical tempering. After 7-tank ultrasonic cleaning, the coating remains intact and does not fall off. Table 1 lists the basic properties of some coated glasses.

[0040] Table 1. Basic properties of some anti-glare coated glasses

[0041]

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com