Water-based anti-radiation acrylic polyurethane finishing paint

An acrylic polyurethane, anti-radiation technology, applied in the field of paint, can solve the problems of water resistance, chemical resistance, radiation resistance, wear resistance and weather resistance, etc., and achieve good wear resistance, high hardness and strong adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

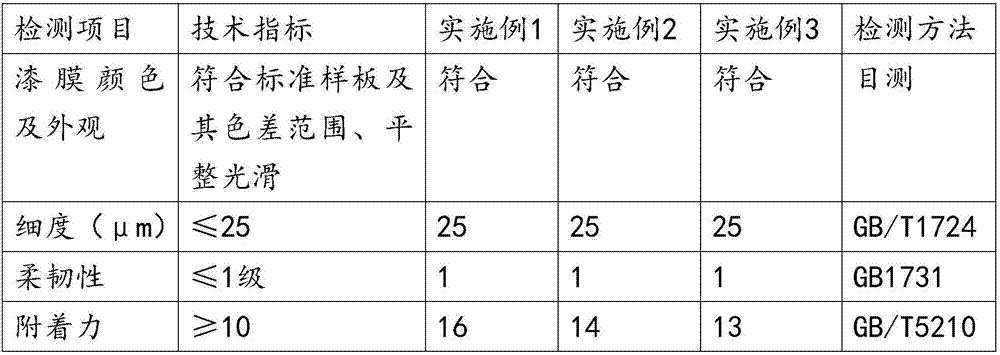

Examples

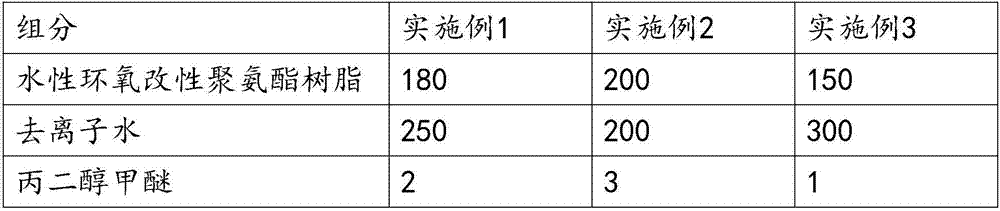

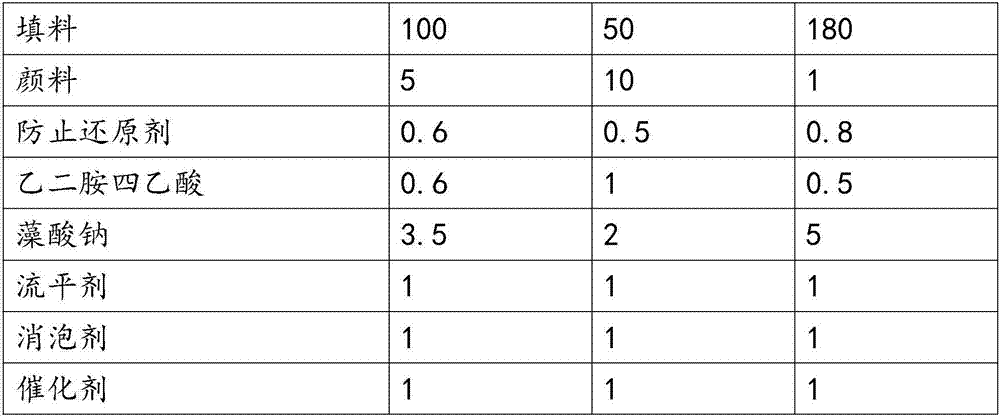

Embodiment 1-3

[0021] The preparation method of embodiment 1-3 is as follows:

[0022] (1) Pump the water-based epoxy modified polyurethane resin (PUD) into the batching kettle for stirring, the temperature in the kettle rises to 55-60°C, and keep it under stirring for 5 minutes;

[0023] (2) Open the pure water tank and the propylene glycol methyl ether head tank valve, add half of the amount of deionized water and the entire amount of propylene glycol methyl ether and sodium alginate, stop heating when the steam temperature in the kettle reaches 65-70 ° C, and at the same time Start the stirring function to heat the material evenly and stir for 20-35 minutes;

[0024] (3) After stirring evenly, add fillers, pigments and ethylenediaminetetraethylene, stir at high speed for 20 minutes, then pump into a sand mill and grind until the fineness is qualified. The reducing agent and auxiliary agent are evenly stirred and tested to be qualified, filtered, pumped into a packaging barrel by a meteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com