Aircraft engine ground direct connection type test air heating device

An aero-engine and air heating technology, which is applied in the direction of measuring devices, internal combustion engine testing, lighting and heating equipment, etc., can solve the problems of complex heater structure and high test cost, and achieve the effect of simple structure, good combustion stability and clean gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

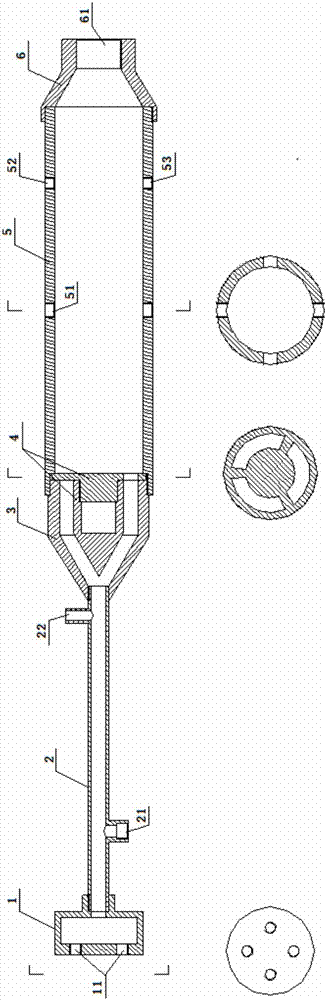

[0014] In order to illustrate the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

[0015] A ground direct connection test air heating device for an aero-engine of the present invention comprises an air inlet pipe 1, a pipe 2, a first adapter 3, a flame stabilizer 4, a combustion tank 5 and a second adapter 6;

[0016] The air inlet pipe 1 is located at one end of the entire heating device, the air inlet pipe 1 is a cylindrical cavity structure with through holes at both ends, and one end of the air inlet pipe 1 is provided with an air inlet 11 for connecting to an external air pressure tank; The other end of the air inlet pipe 1 is connected to the pipeline 2; the other end of the pipeline 2 is connected to the combustion tank 5 through the first adapter body 3; the flame stabilizer 4 is located in the combustion tank 5, and the flame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com